Customized design and manufacture all kinds of purlin shapes and custom design purlin hole styles

Product Name: High Speed Auto Change Purlin Roll Forming Machine With Universal Cutter

Our full automatic High Speed Auto Change Purlin Roll Forming Machine With Universal Cutter has matched hex nuts, with special hexagon spanner, it is more convenient for adjusting different material width. Considering the purlin raw material thickness is bigger, not good feed material head into purlin roll forming machines by manual, we designed the feeding rollers are driven by main motor and transported by sprocket chain, it can save human power when producing.

This purlin roll forming machine is size interchangeable, can produce both c and z sections, see below mark out cassette, it is used for exchanging C and Z type, when the roll forming machine produce C purlin roll forming machine at first, after first c purlin producing task, we need to operate these six cassette: pull out and rotate them 180 degree, next, whole roll forming line can start to roll forming z purlin producing task. Easy operation. The servo motor on right picture is for changing purlin size.

This High Speed Auto Change Purlin Roll Forming Machine With Universal Cutter is pre-punch pre-cut type, we have made one waste material collector under punching and cutting section, it is for collecting punching hole waste material to outside.

All hydraulic pipes are together with screw casing, it is for keeping hydraulic pipes safe and can be used more long time.

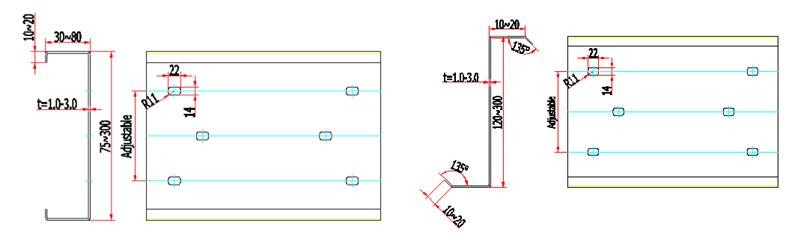

Profile Design Drawing

Suitable material: Zinc coated coil,Galvanized steel coil, Material thickness: 1-3mm, 2.5mm for inspection (common used), material Yield<=Q345Mpa.

Technical Parameter

|

Parameters

|

Specification

|

|

Voltage

|

380V/50HZ/3PH

|

|

Driving Motor

|

18.5KW

|

|

Hydraulic Cuting Motor

|

5.5KW

|

|

Motor For Width Adjust

|

0.75KW*3

|

|

Forming Steps

|

18

|

|

Working Speed

|

15-20m/min

|

|

Thickness for Steel

|

1.0-3.0mm (Material:PPGI,GI Steel G550)

|

|

Shaft Diameter

|

80mm

|

|

Shaft Material

|

High grade 45# forged steel

|

|

Roller Material

|

Gr15 steel with polished and heat treatment

|

|

PLC Cabinet

|

Schneider, Delta

|

|

Encoder

|

Omron

|

|

Sprocket Wheel

|

45 steel high-frequencies quench

|

|

Cut-off System

|

Post punching post cutting

|

|

Cutting Blade Material

|

Cr12 steel

|

|

Machine Frame Material

|

Fine welded structural steel;

|

|

Roofing Material

|

PPGI, GI steel G330-550

|

|

Painted Color

|

Blue+Gray White Or Customization

|

|

Overall Size

|

9000*1400*1800mm

|

|

Weight

|

9500KGS

|