Front Idler Assembly OEM Excavator Undercarriage Parts

1. Why Choose Us?

-

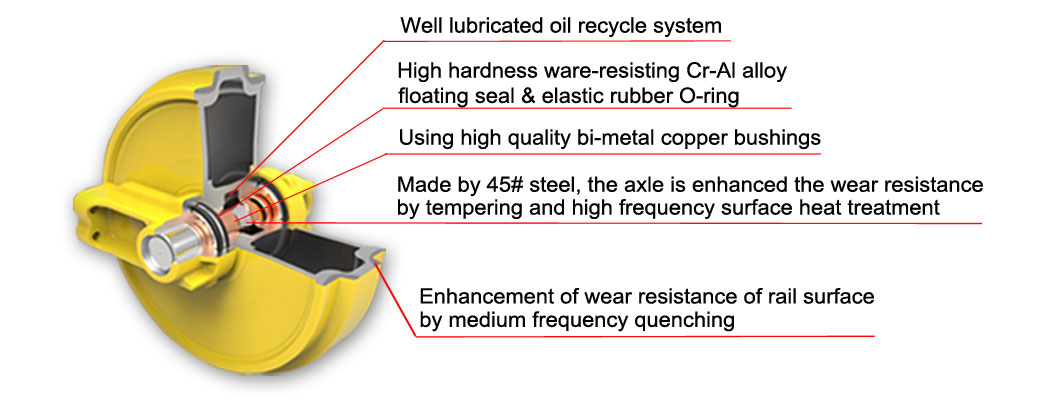

We

use high quality material to ensure quality and consistency, and our heat

treatment process provides hardness in high wear areas, and elastic core to

resist shock and impact loads.

-

Through quench-tempering processes to ensure excellent mechanical properties, high strength and superior wear resistance to avoid bending and breakage.

-

Advanced Germany KUKA automatic machining center, horizontal and vertical CNC machining ensure the accuracy of assembly dimensions.

-

Our quality control is strictly performed from sourcing raw materials and different machining procession to final packing.

-

After-sale services: video technical support, 24 h online support

2. Professional Idler Production Processes

3. Main Idler Dimensions of Installation

Main Parameters

|

Brand

|

Model

|

Main

Dimensions of Installation

|

|

A

|

B

|

D

|

L

|

M

|

N

|

O

|

|

HITACHI

|

EX40-3

|

358

|

318

|

92

|

240

|

140

|

60

|

40

|

|

EX100-1

|

490

|

450

|

134

|

90

|

260

|

70

|

65

|

|

EX120-1

|

490

|

450

|

134

|

90

|

260

|

70

|

65

|

|

EX150-1

|

544

|

510

|

140

|

80

|

260

|

70

|

75

|

|

EX200-5

|

537

|

500

|

160

|

80

|

287

|

64

|

65

|

|

EX220-5

|

537

|

500

|

160

|

80

|

287

|

64

|

65

|

|

EX270-1

|

575

|

530

|

204

|

130

|

324

|

70

|

85

|

|

EX300-5

|

617

|

570

|

204

|

130

|

324

|

70

|

85

|

|

EX400-1

|

675

|

625

|

205

|

108

|

333

|

85

|

110

|

The models above are just for reference, we can't list all models here. We can supply more products as your requirements. Please feel free to send us your inquiry.

4. Compatible Brands

5. Hot Sale Products