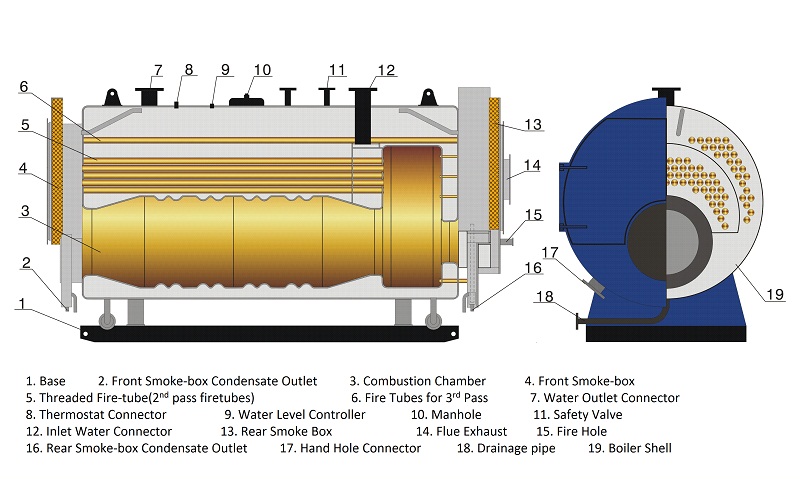

Devotion Oil Fire Steam Boilers Structure

Features of Devotion Oil Fire Steam Boilers

-

The Boilers are three pass, wet back structure which ensure higher safety and reliability.

-

Two groups of fire tube symmetrically arranged contribute to boilers being evenly heated thus prolong service life.

-

Corrugated hearth design effectively prevents damages resulted from expansion and contraction, thus deliver a safer boilers for users.

-

Threaded smoke tubes can increase heat transfer so as to improve heat efficiency.

-

High efficiency due to enlarged heating surface thanks to larger combustion room design, which also reduce the boiler volume and NOx discharge.

-

Multi level sealing for front and rear smokeboxes ensure no smoke leakage;

-

Lager steam space, better quality steam;

-

High-efficient insulation materials results in low boiler surface temperature. The heat dissipation loss may be ignored;

-

The boiler control system is applicable for long-term operation under high temperature and high humidity environment;

-

PLC control system is adopted to realize the complete and stable interlocking protection of temperature, pressure and water level, the manpower guarding isn’t required.

-

Boilers are manufactured and tested in compliance with Chinese national standards. All pressurized parts are made from high quality steels from well-known steel plants.

-

Each boiler must undertake a series of inspections and tests before leaving the factory, such as Non-destructive test and hydraulic tests.

-

All components and auxiliary equipment like burners, pumps, water level gauge, safety valves are supplied by renowned brands.

-

Easy maintenance with availability of man holes and hand holes.

-

A patented economizer (optional) can save 15% fuel and reduce noises.

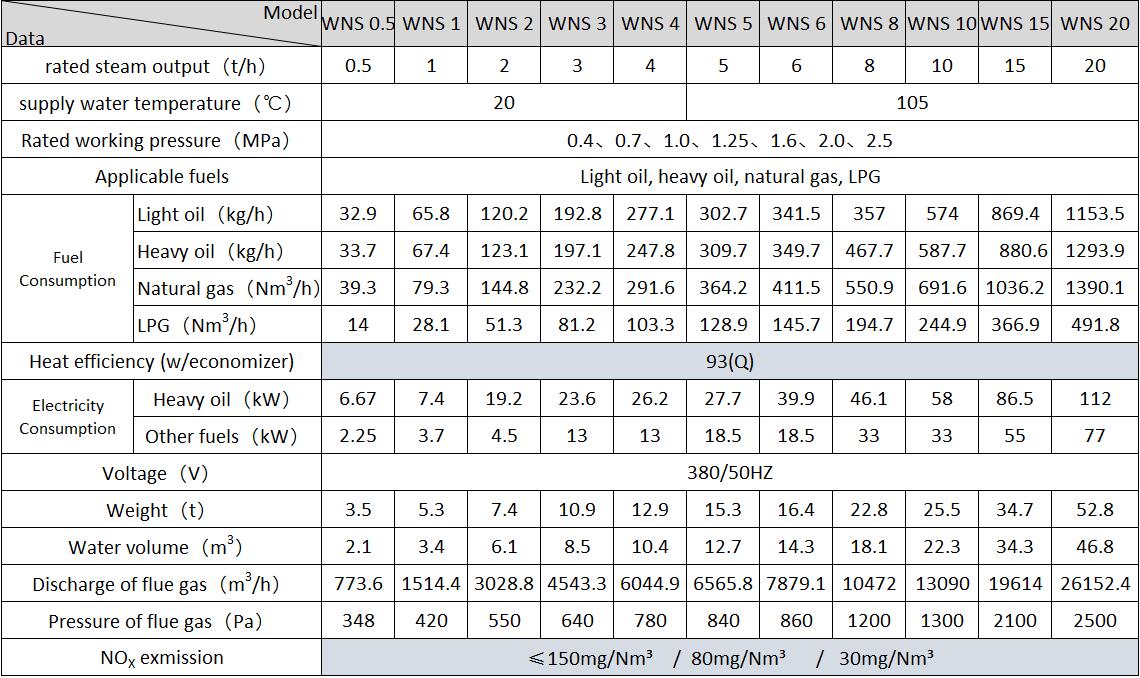

Oil Steam Boiler Technical Data

Notes:

1. The rated pressure of each model of boiler is available at 0.4, 0.7, 1.0, 1.6, 2.45Mpa

2. The low heating values of different fuels are calculated as follows:

Light oil: 42875kJ/kg(10240kcal/kg)

Heavy oil: 41870 kJ /kg(10000kcal/kg)

Natural gas: 35590kJ /Nm3(8500kcal Nm3)

LPG: 100488kJ / Nm3 (24000kcal/ Nm3)

3. Parameters in the above sheet shall be adjusted subject to changes of heating values or chemical composition.

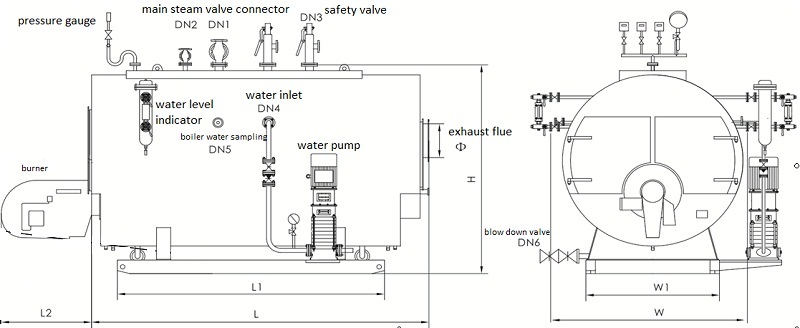

WNS Oil Steam Boiler Installation Diagram

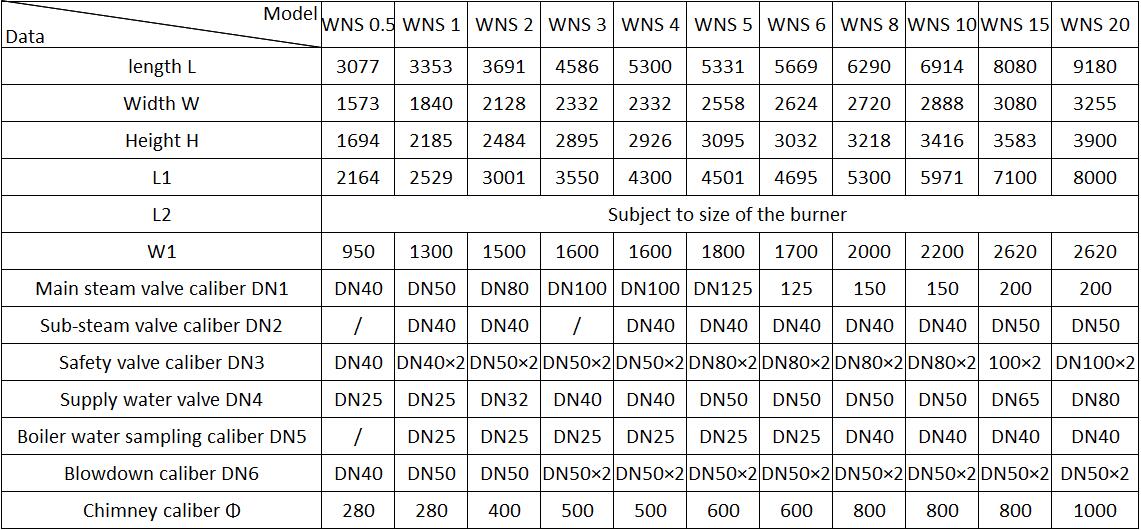

WNS Oil Steam Boiler Installation Dimension

Note: The above data are subject to changes without prior notice for pursuit of innovation and continuous improvement on products.