Product Item: Industrial Ceramic Piston Parts

Comparison Properities of different material pumps:

|

Properties Product Name

|

Chromium Pumps

|

Glass Pumps

|

Ceramic Pumps

|

|

Hardness(Vickers)

|

5-7

|

8-10

|

≥13

|

|

Porosity

|

1.5

|

5

|

0

|

|

Supereme Suitable Temperature

|

300°C

|

250°C

|

1000°C

|

|

Acid resistance

|

Acid nonresistance

|

acidproof

|

acidproof

|

|

Alkali resistance

|

Alkaliproof

|

Alkal nonresistance

|

Alkaliproof

|

|

Roughness of Surface

|

≥1.0μm

|

≥2.5μm

|

≤0.2μm

|

|

Lifespan(Ten thousand times)

|

≈300

|

≈50

|

≥1000

|

|

Particle release

|

More

|

Most

|

Few

|

Wide Useage of Ceramic Pump:

* Liquid of filling machines made in China;

* Liquid filling machines, such as BOSCH, B+S, GROENINGER, made in Germany, Italy, America and Japan.

* Pharmaceutical: Topicals and parenterals: injectable in vials, ampules, syringes, enema… Enterals: syrups, capsules, drop…

* Liquid food: Beer, beverage, dairy, wine, edible oil…

* Cosmetics: Perfumes, lotions, creams, pastes, shampoo and make-up...

* Others: ink, reagents, chemicals.

Quality Insurance:

* Product quality standard and application function of finished product testing system

Finished appearance and physical dimension standards (roughness, roundness, straightness, cylindricity and 3D surface scan);

Application

Function of Finished Product testing system (airtightness, measuring

accuracy, rotproofness and fire resisting quality testing).

Material Specification

|

Material

|

Alumina

|

Zirconia

|

Silicon Carbide

|

Silicon Carbide

|

Hot pressZrO2

|

|

|

(Al2O3)

|

(ZrO2)

|

(SiC)

|

(Si3N4)

|

|

|

Color

|

White

|

Light Yellow

|

White

|

White/ transparent

|

White

|

Black

|

Dark Grey

|

Dark Grey

|

|

Purity(%)

|

96

|

99.5

|

99.7

|

99.99

|

3Y-TZP

|

——

|

——

|

——

|

Density

(g/cm3)

|

3.7

|

3.9

|

3.93

|

3.97

|

6

|

3.2

|

3.25

|

6.07

|

Hardness

(HRA)

|

87-91

|

88-92

|

99-93

|

89-93

|

84-87

|

90-94

|

89-92

|

89-91

|

|

Bending Strength(MPa)

|

350

|

370

|

390

|

390

|

1000

|

400

|

700

|

2000

|

|

Compression Strength(MPa)

|

3000

|

2350

|

2300

|

200

|

3500

|

——

|

3800

|

4000

|

Fracture Toughness

(MPa/m)

|

4

|

4

|

4

|

4

|

7

|

4

|

5

|

8

|

Thermal Expansion Coefficient

(x10-6/°C)

|

7.2

|

7.2

|

7

|

7

|

10

|

3.7

|

3.2

|

9.5

|

Working Temp.

(°C)

|

500

|

1200

|

1600

|

1600

|

200

|

——

|

1100

|

300

|

|

Thermal Shock Resistance

(°C)

|

200

|

250

|

200

|

200

|

200

|

400

|

550

|

200

|

Note: All the above specifications are provided by our testing center, which is certificated by CNAS.

Applications

Pharmaceutics

Topical and parenterals: inject able in vials, ampoules, syringes, enema.

Entrails: syrups, capsules, drop

Liquid Food

Beer, beverage, dairy, wine, edible oil.

Cosmetics

Perfumes, lotions, creams, pastes, shampoo and make-up.

Others

Ink, reagents, chemicals.

Perfusion Scope and Precision of Ceramic Pump

Perfusion Volume Scope: 0.1-2000ml or custom design.

Super High Perfusion precision: perfusion transmitter is water for injection)±0.25%

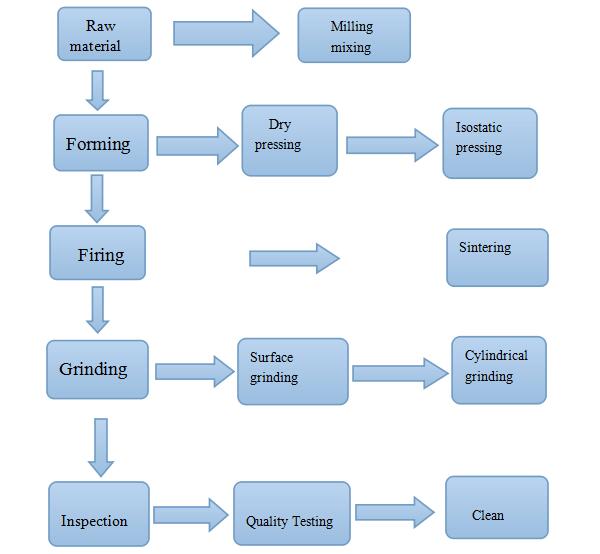

Production process

Special offer: Most of our crucibles are produced to order, please mark clearly height, bottom diameter, top diameter, wall thickness and any special requirements i.e. lips etc. To speed up quotations please supply a drawing and if appropriate, the name of the system in which they are to be used.