Industrial Electrical Pole Silicone Rubber Gaskets

Pole silicone rubber gaskets has outstanding high and low temperature resistance, keeps good elasticity in the temperature range of -70℃-+260℃, and has the advantages of ozone resistance, weather aging resistance, suitable for sealing gaskets in thermal machinery. Without any toxicity can be made of insulation, insulation products and medical rubber products. At the same time, it has waterproof, flame retardant, high temperature resistance, electric conductivity, wear resistance, oil resistance and other advantages.

Characteristics of silicone rubber gasket:

● High reliability

● High compressibility, soft and elastic

● Low thermal conductivity

● Natural viscosity, without additional surface adhesive

● Meet ROHS, SGS and UL environmental requirements certification

● A variety of color options, bright colors, customizable shapes.

● Raw materials are 100% food grade environmental protection silica gel.

● Low carbon environmental protection, non-toxic and tasteless, soft, anti-slip, shockproof, anti-seepage, heat insulation, not easy to aging, not easy to fade, easy to clean.

● Durable, effectively protect the surface of furniture from scald and scratch.

● Temperature range: -40 ~ 230 degrees Celsius. Baked and frozen, it remains soft and undeformed.

Below is our industrial electric power silicone rubber parts:

Experience: More than 20 years experience in rubber OEM production

Shape: According to customer's drawing

Package: PE bags, Cartons,Pallet

Payment Terms: T/T,L/C and so on.

Sample time: 25-30 days

Shipment Way: Vessel,Air,Express etc.

Q1.Which kind of product do you produce?

Kingtom:Rubber injection parts,rubber compression parts and rubber extrusion parts,rubber-metal parts,plastic parts.

Q2.What information do you need for making price?

Kingtom:1.2D/3D drawing,or samples photo with detail size.

2.Material And Material hardness

3.Detail quantity

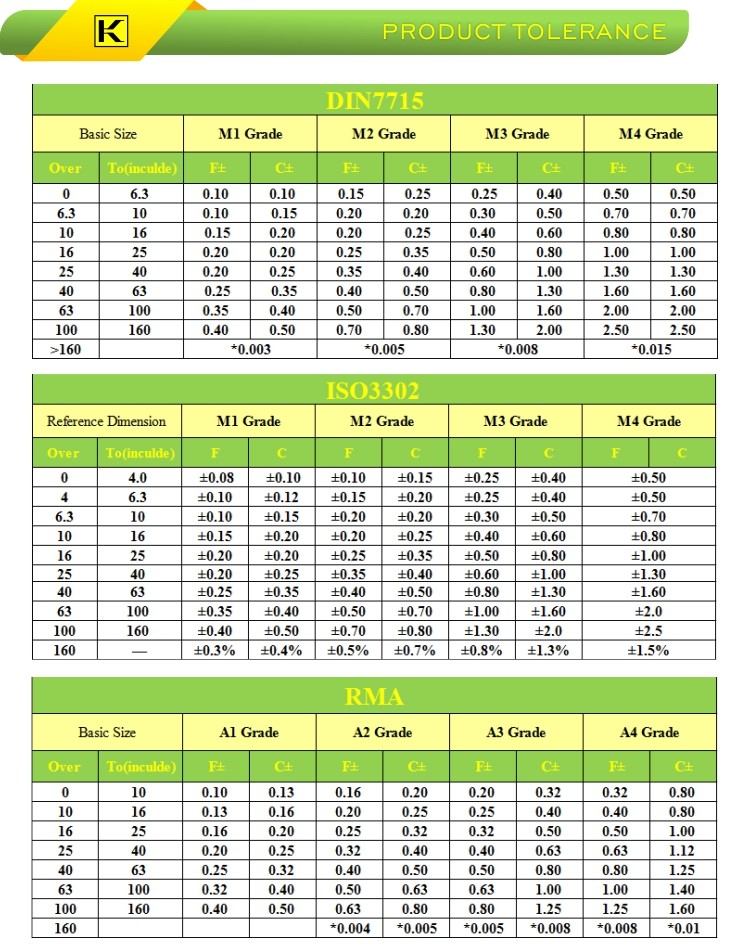

4.Your other requirements like tolerence,surface treatment.

5.Product usage environment

Q3.I don't have 3D drawing,how should i do ?

Kingtom:You can send one sample to us,then we can produce as your sample.

Q4:How to make sure the quality?

Kingtom:Check the samples before mass production.

There is the detail inspection report and goods photos before shipping.

Q5.Do you provide samples?

Kingtom:Yes,samples is free and you just pay the express cost.

Q6.How is the delivery time?

Kingtom:It usually takes 10-30days.It depends on the orders.