Stainless steel PSA nitrogen gas generator for medicine / food

PSA Principle

PSA ( Pressure Swing Adsorption ) is an advanced gas separation technology, based on the physical adsorption of the internal surface in the adsorbent to gas molecules, separating the gas by the characteristics of absorbing to the quantity of different gas in general pressure.

The CMS (carbon molecular sieve) is a sorbent picked up from the air, used in separating oxyen and nitrogen molecular. As picture shown, the adsorption quantity of CMS is greatly higher to oxygen than nitrogen does with the same pressure.

PSA nitrogen generator produces N2 gas, using air as raw materials and carbon molecular sieve as adsorbent, by the selective adsorption of carbon molecular sieve to O2 and N2, achieving the separation of the N2 and O2 in the air.

PSA nitrogen producing,with PSA nitrogen has the characteristics of simple process, high automation, fast gas production (15~30 minutes), low energy consumption, high purity and purity which can be adjusted in a large range according to the needs of the user, convenient operation and maintenance, low operating cost and strong adaptability of the device. Small and medium sized nitrogen users are widely used below 3000Nm3/h. PSA nitrogen has become the preferred method for small and medium-sized nitrogen users.

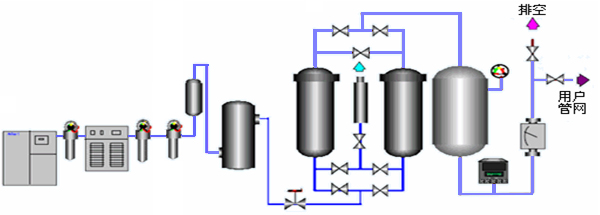

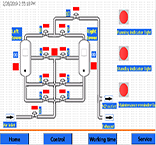

Nitrogen Gas GeneratorSystem

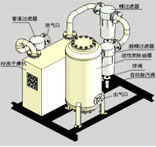

1.Compressed Air Purification System

Carbon molecular sieve is the key material to affect the production of nitrogen generator, as the compressed air provided by compressor usually contains oil and water, which will reduce the adsorption capacity of carbon molecular sieve, so oil and water must be filtrated firstly from the compressed air which will be carried into O2/N2 separation system.

First the air compressed by the compressor to 0.75-1.0 MPa is carried into the air purification system , and then pipelines filters help to remove most water, oil and machinery impurities from the air, the pressure dew point of air reach 2℃ -10 ℃ by the freeze-drying machine, the clean air will be get by purified through the fine filters, ultra-precision filter and activated carbon for oil removal in turn.

Compressed air purification system is composed by pipelines filters, freeze-drying machine, fine filters, ultra-fine filters, the activated carbon for oil removal, sewage automatic valves, ball valves, and other components.

2.Air Tank System

The role of air tank systems is to smooth the gas transmission of O2/N2 separation system, preventing too rapid flow velocity in the switching transient, air tank system could impact the purification of air, and help to extend the natural life of carbon molecular sieve.

Air tank system is composed by air tank, safety valve, closing valves, ball valves, pressure gauges etc..

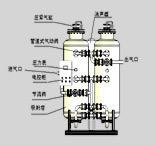

3.O2/N2 Separation System

O2/N2 separation system is the core of N2 generator. Its main part is two towers filled with carbon molecular sieve ,when the compressed air get into adsorption tower, the O2, CO2 and H2O is absorbed by carbon molecular sieve, N2 is produced from the export terminal . When one tower produces N2, another tower release the O2, CO2 and H2O by reducing the pressure to get the renewable desorption of carbon molecular sieve. Two towers alternate adsorption and regeneration to output N2 continuously.

O2/N2 separation system is composed by tow tower filled with carbon molecular sieve, pneumatic valve, muffler, throttle, clamping cylinder, pressure gauges etc.

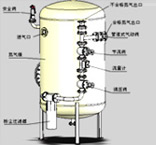

4. Nitrogen Buffer System

The main role of N2 buffer system is to balance the pressure and purity of N2 which separated from O2/N2 separation system to ensure continuous supply of N2.

Nitrogen buffer system is composed by buffer tank, flowmeters, dust filters, pressure regulating valve, throttle, safety valve and so on.

5.Electrical Control System

Electrical Control System is to control start-up & shutdown operation, the status light, sound and light alarm fault instructions, purity display, driving pneumatic valve by setting procedures etc.

Electrical Control System is composed by the process controller CPU, triple gas source, electromagnetic valves, lights etc.

Advantages

|

High purity.

The 99.9995% nitrogen gas is produced in one-time procedure without purification devices.HUILIN Nitrogen Generator produces the high-purity N2 preponderate over 99.9995% in one-time, which depends on the professional molecular sieve and special high-purity technics flow.

|

|

|

Excellent energy-saving

Unique distribution of gas flow, advanced energy-saving technology, excellent molecular sieve make HUILIN Nitrogen Generator energy-saving achieve 10~20% than other do.

|

|

steady-going, long life-span

Unique clamping cylinder technology effectively extending the life of molecular sieve.

|

|

High degree of automation

The automatic control technology could switch machines with one key, and have remote and centralized operation with nobody contro

|

Specification

|

Model

|

N2 Purity

(%)

|

N2 Capacity

(Nm3/h)

|

N2 Pressure

(MPa)

|

N2 Dew Point

(℃ )

|

|

WG-STD 97

|

97%

|

5~3000

|

0.2MPa lower than air resource ( adjustable)

|

≤-45 ℃

|

|

WG-STD 98

|

98%

|

4~2500

|

|

WG-STD 99

|

99%

|

3~2100

|

|

WG-STD 295

|

99.5%

|

2~1800

|

|

WG-STD 39

|

99.9%

|

1.5~1300

|

|

WG-STD 49

|

99.99%

|

1~800

|

|

WG-STD 495

|

99.995%

|

1~750

|

|

WG-STD 59

|

99.999%

|

0.5~500

|

|

WG-STD 595

|

99.9995%

|

0.5~400

|

Tips:

1>If no special demands by the user,the mode.specification and basic performance parameters are different with this standard,that in accordance with the contract regulation.

2>There are micro-Helium, Neon, Argon etc. Inert gases in the N2 purity.

3>Flow unit “Nm3/h”is pointed to 20℃, in the state of 0.101MPa (absolute pressure).

4>The pressure number are gauge value unless otherwise specified.

5>The dew point number is under normal pressure value unless otherwise specified.

Why choose us

1. We have more than 10 years of experience in air separation equipment and have rich experience in facing all difficulties.

2. Our delivery cycle is short. The soonest we can deliver the goods is 15 working days since we pay the deposit.

3.We have professional engineers in charge of after-sales service, which can be provided anywhere in the world.

4, we have a unique technology, so that the life of the molecular sieve more than 10 years.

All our machines are fully automated and there is no need for guards.

6. Our machines save 10%~20% more energy than our counterparts.

Detail Photo