Product Name: Injection Molded Plastic Case for Face Cleaner

Production Introduction: Making the case from ABS, and then make chrome plated over the edge & assemble with soft-touch silicon, we can finally have a lovely face cleaner.

Mold cavity: S136/H13

Mold Base:LKM/HASCO/DME

Surface treatment: Polishing/Texture/Etched/Sand Blasting

Runner: Hot runner (Yudo, Moldmasters, Husky, Hasco, Synventive, etc.)

Shaping mode: Plastic Injection Molding

Mold lifetime: 100,000~1,000,000 shots

MOQ:1set

Mold lead time: 3~7 weeks for T1

Production lead time:2~5 weeks, according to order qty

Mold payment terms: 50% deposit

by

T/T against PO, balance by T/T after approval of samples but before shipment

Products payment terms: 30% deposit by T/T against PO, balance by T/T before shipment

Port of loading: Xiamen or other China port, as per customers'

requirements

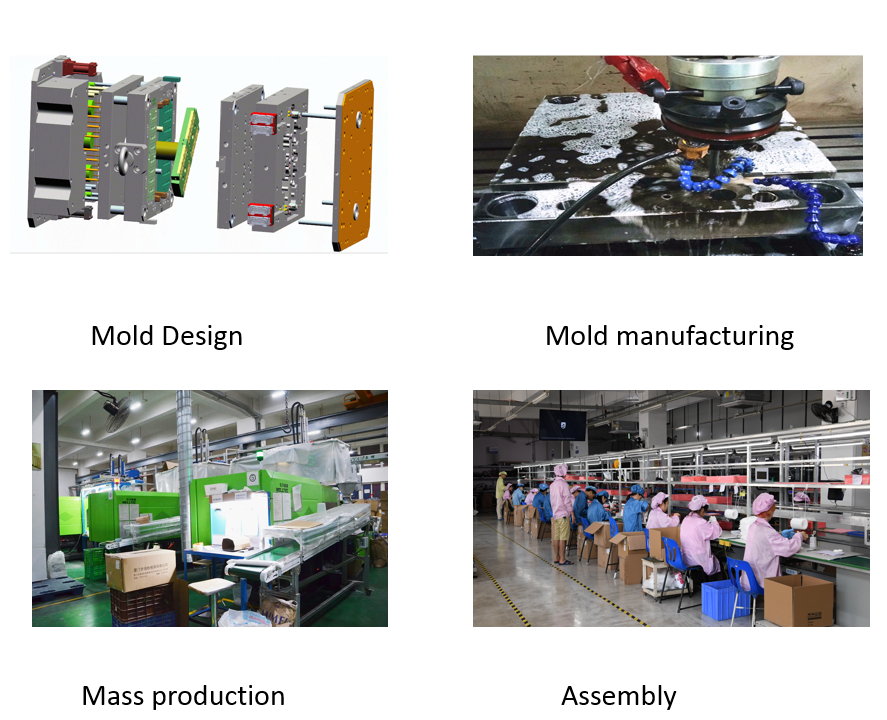

QQS Moulds provides services of plastic part design,

prototype making, mold design, mold production, mass production in house.

Moreover, we have reliable partner for painting, PCBA making and final

assembly. We are working with many clients both home and abroad, and we keep

every process very transparent with customers, because we hope to have a

win-win situation for both parties.

Q: Can you also make the silicon on plastic casing of face cleaner?

A: Yes, we can outsource this for you, and provide all in one services for customers.

Q: For

the plastic case of projector, can you make the mold without part drawing?

A: Yes, if customers cannot provide 3D

drawing, we can only develop the mold as per sample.

Q: Do you have injection machine to

produce the parts?

A: Yes, we have our own

injection shop, so we can make the production & assembling for customers,

if request.

Q: What

kind of molds are you making?

A: We mainly make plastic

injection molds, but we can also build compression molds (for UF or SMC

material) & die casting molds.

Q: How long does it take to build

a mold?

A:It varies a little depending on the product sizes and complexity of part,

generally speaking, a medium size mold can be finished for T1 within 25~30

days.

Q:

Is it possible for us to know the schedule of molds without visiting your

factory?

A:Upon the contract, we will send you a mold production schedule, and during

the production, we will keep you updated by weekly report with related

pictures. So, you can know the schedule of your molds clearly.

Q:

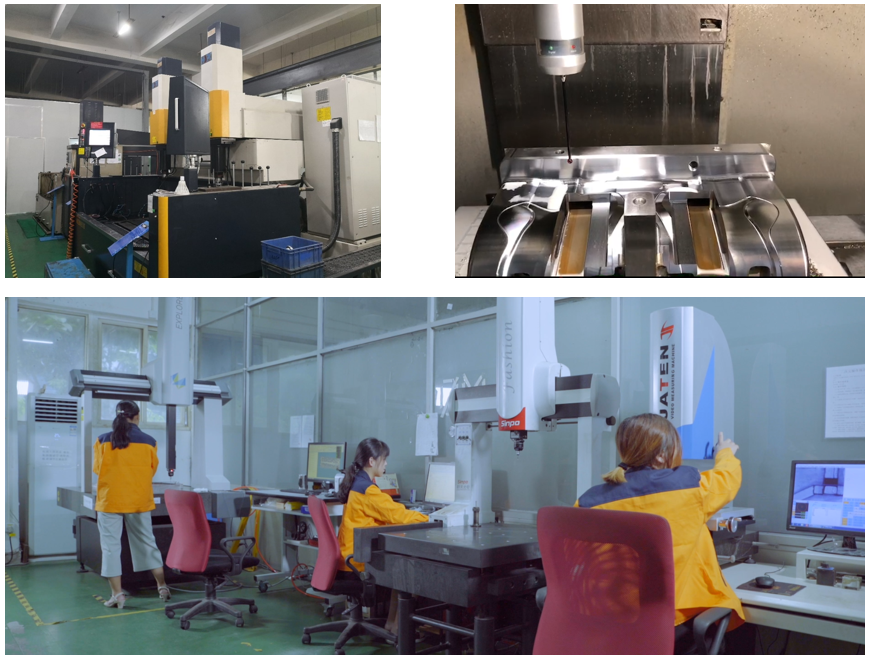

How do you guarantee the quality?

A: We will appoint a project manager to follow your molds, who is responsible for every process. Besides that, we have QC for every procedure, and we will also have CMM & online inspection system to guarantee all components to be within the tolearance.

Q: Do you support OEM ?

A:Yes,

we can produce by technical drawings or samples.

Q: What kind of resin do you proceed

with?

A:We proceed with both thermoplastic and thermoset.