1 Product Parameters

|

Specifications

|

|

Type

|

Insulated Cold Storage Room Sandwich Panel

|

|

Density

|

40~45kg/m³

|

|

Thickness

|

40/50/60/75/80/100/120/150/200mm

|

|

Metal skin thickness

|

0.4~0.8mm

|

|

Panel Effective Width

|

1000mm for wall and roof

|

|

Skin material

|

PPGL,PPGI,Stainless steel,aluminum coil

|

|

Pre-painted

|

PE/SMP/HDP/PVDF etc.

|

|

Fireproof Grade

|

B1

|

|

Thermal Conductivity

|

≤0.023/≤0.02

|

|

Temperature Range

|

40~43/40~50℃

|

|

Length

|

Max 11.9m or Customized.

|

|

Customized design is welcomed.

|

2 Product Features

Excellent insulation performance

The thermal conductivity is between 0.019-0.022w/m·k, which is the lowest thermal conductivity in the current practical application of thermal insulation materials. Using high pressure continuous foaming technology, the foam is uniform and dense, the cell density is up to 200,000 /cm³, the closed cell rate is up to 97%, and the water absorption is very low, which can effectively prevent the infiltration of water vapor, so as to play its excellent thermal insulation performance.

Good fire resistance

Polyurethane foam has excellent fire resistance, forming a coking protective layer during combustion, which will not melt and drip like EPS and XPS. The flame retardant property can be further improved by combining with metal surface material. Combustion performance reached the national standard 8624-2012 B1 level.

Leading pentane technology

Using non-fluorinated raw materials for one-time high-pressure foaming, no chlorofluorocarbons, room temperature effect is 0, no pollution to the environment, Conform to the international convention on the ozone layer and European environmental standards.

Proprietary airtight technology

Using proprietary airtight structure technology makes the adjacent plate joint insulation layer more organically integrated into one, natural, eliminate "cold steam bridge", greatly improve the airtight performance, more suitable for air conditioning warehouse.

Energy saving, consumption reduction and environmental protection

The selection and processing of polyurethane board strictly follow the national and industry environmental standards, and the board is not easy to breed bacteria and parasites during use, which ADAPTS to various complex situations and stringent environmental requirements in the cold chain industry. The cold storage insulation system of the proprietary plate airtight structure technology connects the cold storage body organically, realizes absolute airtight, saves energy consumption by 30%, and greatly reduces operating costs.

Easy and quick installation

Plate factory prefabricated, installation system design mature, meet the all-weather construction needs, shorten the installation cycle, reduce labor costs and material loss.

3 The Technical Specifications of Cold Storage Sandwich Panels

|

Thickness /mm

|

Temperature difference between inside and outside/℃

|

Height of wall panel/m

|

Length of roof panel/m

|

Applicable cold storage temperature/℃

|

|

100

|

30

|

5

|

4.45

|

-15

|

|

125

|

35

|

5.5

|

5.2

|

-20

|

|

150

|

50

|

6

|

5.85

|

-25

|

|

175

|

65

|

6.5

|

6.3

|

-30

|

|

200

|

75

|

7

|

6.8

|

-40

|

The data shown in the left table are only available for the panel which subject to the internal-external pressure difference and contraction pressure, without wind load. If the specified length/height is exceeded or wind load occurs, panel supporters are required.

The above data are calculated according to the heat flow of 8~10W/m2.

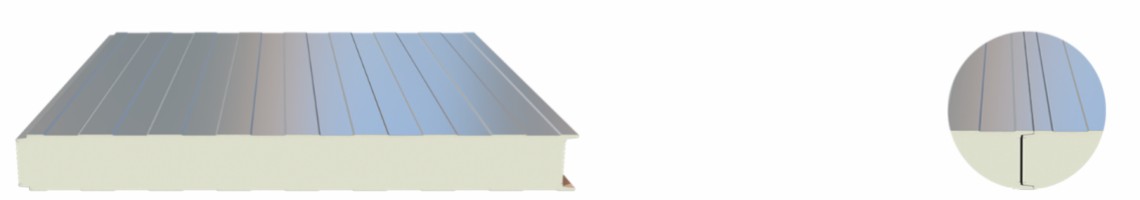

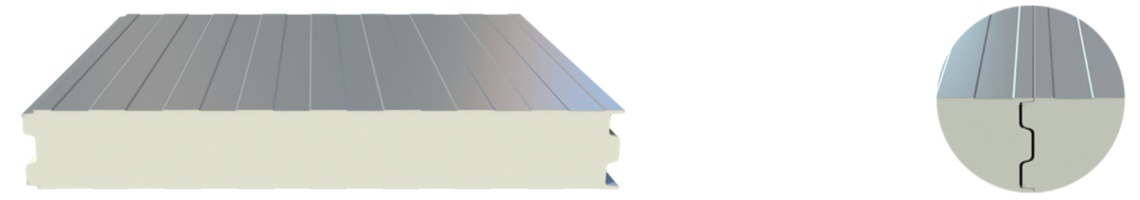

4 Plate Type and Node Figure

Cold storage board plug-in interface-C type

Cold storage board plug-in interface-E type

5 Application Areas of Cold Storage Panels

·Fast frozen processing and refrigeration of food

·Food processing plant

·Storage of dairy products

·Biological products and medicines

·Indoor cold storge

·Cold storages for cold-chain transportation vehicle