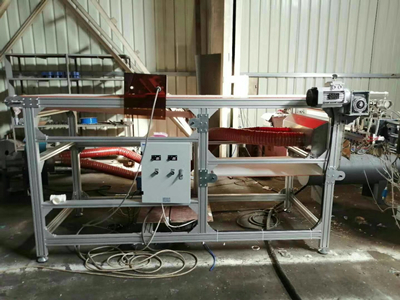

PP Melt Blown Nonwoven Fabric Extrusion Machine

Quick Details

|

Condition

|

New

|

Application

|

sheet

|

|

Plastic Processed

|

PP

|

Screw Design

|

Single-screw

|

|

Place of Origin

|

Guangdong, China

|

Brand Name

|

LianXin

|

|

Voltage

|

220v, 380v, 400v, 415v

|

Dimension(L*W*H)

|

9000*1000*2500mm

|

|

Weight

|

3t

|

Certification

|

CE ISO9001

|

|

End product

|

PP Melt Blown Nonwoven Fabric

|

Inverter

|

ABB Brand

|

|

Thickness

|

Customizable

|

Color

|

Customizable

|

|

Warranty

|

12 Months

|

Diameter

|

Customizable

|

|

L/D

|

25-28

|

Screw Dia(mm)

|

45~80

|

|

Power(W)

|

22kw

|

Automatic Grade

|

Automatic

|

XINHUA design and manufacture the small melt blown fabric machine which is particularly suitable for making melt

blown roll fabric of the face mask production of different width and weight/㎡. Different melt blown fabric Width and

weight can be adjusted on our machine by adjusting the screws, roll collector, etcs.

Product details

|

Special design screw

The melt blown process is a nonwoven manufacturing system involving direct conversion of a polymer into continuous filaments, integrated with the conversion of the filaments into a random laid nonwoven fabric.

|

|

|

|

Hanger mould

The melt blown process involves the attenuation of the filaments using high-velocity hot air streams that impinge on the extruded filaments as they are emerged from the extrusion nozzles to obtain much finer filaments.

|

|

|

|

|

Condensation screen or roller

Polymer melt extruded from the nozzle hole of die head by using high-speed hot air flow to draft the thin flow, so as to form a microfiber and collect it in roll type fabric on the condensation screen or roller, at the same time, charging statics by static charger to make the melt blown fabric surface able to absorb more particles to realize a much high level filtration.

|

Transmission system and Cutter

1.high capacity ,stable

2.Solution metering pump technology: a specially designed solution metering pump, through accurate pressure measurement in front of the pump, the use of microcomputer processing to adjust the speed of the extruder, maintain pressure stability, orderly supply logistics to optimize the feeding process, to ensure the stability of the head mold extrusion;

3. Extrusion mold and spinneret parts; Divided into vertical and horizontal structure, so that the production of spun bonded non-woven cloth net evenly spread, strong, good permeability;

|

|

More machine details :

Why Choose Us

FAQ

Q: Are you a factory or trading company?

A: We are a factory in Guangzhou, welcome to visit and check at any time.

Q: What’s the lead time for a whole production line usually?

A: About 25-60days or depends on different production lines.

Q: Will your company offer install and guide service door to door?

A:Yes, oversea installation service is available.

Q:How to deal with the machine problem after 1 year free warranty?

A:1. 24 hour telephone technical service

2. Offer spare part with cost price

3. Door to door service again .

Q: If your company has passed some certificates?

A: Yes, we have passed CE, ISO.

If you are interested in our plastic pipe extruder machine,Contact now! Tell us the details of your needing.