L Shaped Gold Coated Double Tube NIR Infrared Emitter for Lamination Glue Activation

Brief introduction of Short Wave IR Heater

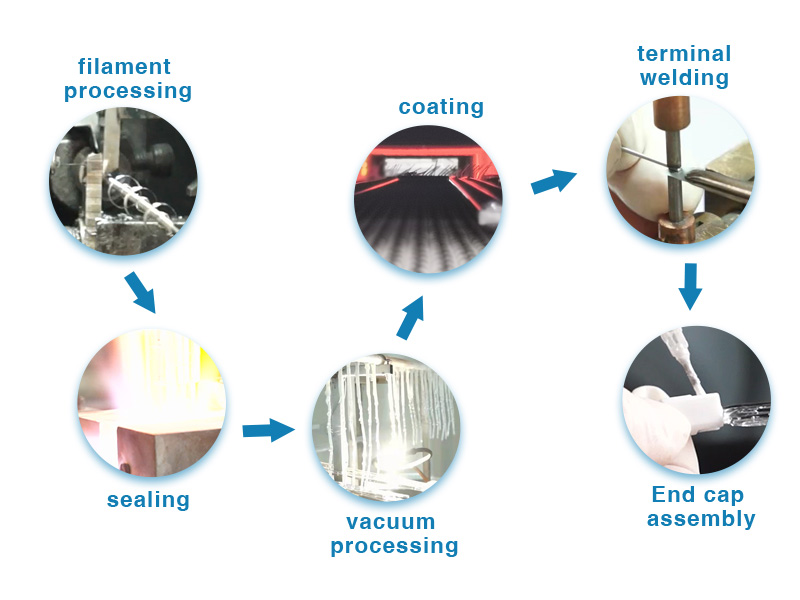

Short wave quartz infrared heaters are used in various industrial applications. It contains tungsten filament, helically wound, encased in quartz envelope. Tungsten as resistive element is capable of generating temperature in excess of 2750℃. Its response time is very rapid in 1 second it emits over 90% of IR energy. It is by products free & pollution free. Heat focus is very accurate due to compact and narrow diameter of IR tubes. Short wave IR element has maximum heating rate of 100w/cm.

The quartz envelope allows transmission of IR energy and protecting the filament from convective cooling and corrosion. Addition of small percentage of halogen gas in it not only increases life of emitter but also protects blackening of tube and depreciation on infrared energy. The rated life of short wave infrared heater is around 5000 hours.

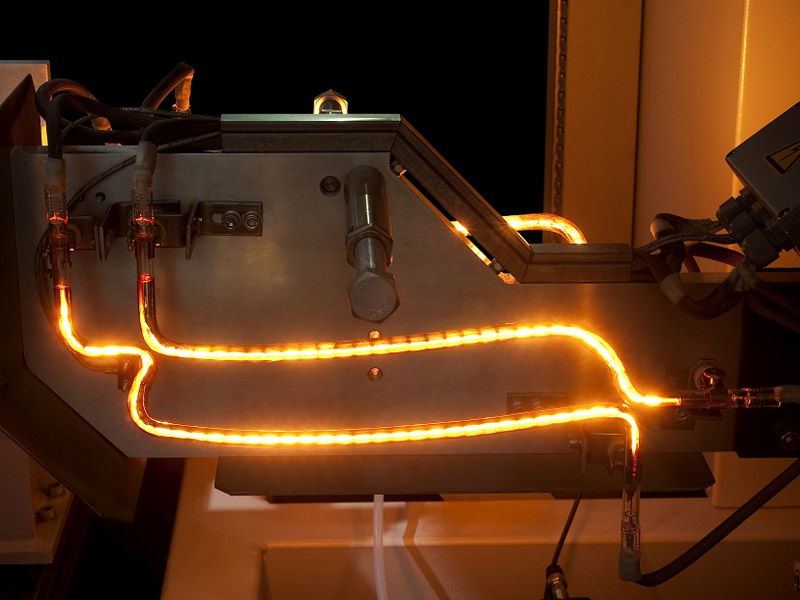

3D contour heaters

All infrared emitters are custom based on clients' requests including shape. out of precise heating, sometimes the 3D contour heater lamps are required based on the heated object property and location. 3D contour heater lamps belong to vacuum lamp like short wave IR lamp and fast medium IR lamp, mostly they are single tubes. And because of the complicate shapes, resin and graphite tooling will be asked for the tube shaping process. Tube shaping is just the first step,then we can start the production of IR heaters, it means 3D heaters take more energy and longer time for finishing compare to straight tube IR lamps.

Lamps' advantages:

Contactless process

Higher strengths

Particle purity

Absolutely air and gas impermeable

Joining of different materials

Simple machine technology, large parameter window

Wide range of IR machines

All types of tooling and emitters

Extensive know-how for all joining processes

Numerous reference

Product applications

PET performs heating in stretch blow moulding machines.

Printing ink drying in offset machines

Pre-heating before embossing

Screen printing curing on T-shirts

Textiles and various such applications

Paint curing

Powder coating

Lacquers drying

Drying glaze on ceramic tiles

Textiles

semiconductor industry

Why choose us

1. The materials used for our lamps are at good quality approval UL testing

2. As a manufacturer of infrared lamps over 10 years history, and we have experienced workers, half of them have worked for us over 5 years

3. We are factory, so we can control the delivery date, material, quality directly

4. For any exclusive-human damage within warranty time, we will delivery the replacements within 3-5 work days once confirming

5. Safe package to protect lamps from being broken during shipping

6. we will provide you the lamp’s clips free of charge ( 2 units clamps for 1 piece lamp)

7. Various Payment methods like wire transfer, paypal, western union

8. Shipping ways provided including DHL, Fedex, TNT, UPS, air, sea

FAQ

1. How to place the order?

Let us know your required lamp specifications including lamp type,diameter, length, power, voltage,reflector...then we send you the

quotation,after payment,production will be started, after finished, they will be shipped to your side.

2. Could you supply clamps for lamp installing ?

Yes, we will provide mounting clamps/clips for clients, and the corresponding clamps quantity with purchased lamps are supplied freely bu us.

3. Could you provide sample for performance testing and appearance checking?

Yes, we can provide the sample based on your required specs.

4. Have an unusual design?

Send us a drawing, sketch, or sample and we'll be happy to quote it.

We specialize in small runs and custom designs, but can be highly competitive on large orders as well.

5. How does your factory do quality control

" quality is priority", we always and keep paying more attention to QC from the material purchasing to the lamps' packing. Our product have gained CE, ROHS, ISO9001.

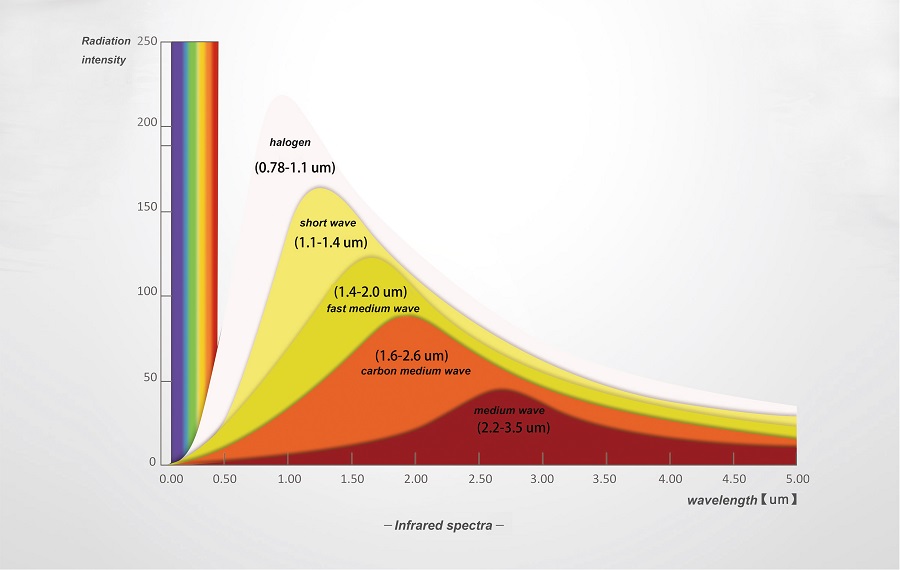

6. Why there are different wavelength IR lamps

All materials including chairs,human body, everything will absorb a fraction of the infrared spectra, reflect a fraction at the surface and allow a fraction of the radiation to pass through. Infrared lamps can realize the heating and drying purpose at a shorter time with less energy but get a good performance only when the infrared radiation which precisely matches the absorption characteristics of the product. Depending on the temperature of the heating filament, an infrared emitter can delivers distinctly different radiation at various wavelengths. Short wave radiation can penetrate deep into some solid materials and ensure a uniform through heating. Medium wave radiation is absorbed mostly in the outer surface and predominantly heats the surface.Medium wave radiation is particularly well absorbed by many plastics,glass and especially water and is converted directly into heat. So we need different lamps at different wavelength for different heating applications requests.