Lab 3L Stainless Steel Spray Drying Equipment

|

Item

|

Unit

|

OLT-S15

|

OLT-S30

|

OLT-S30C

|

OLT-S50

|

OLT-S100

|

|

Max capacity

|

ml/h

|

1500-2000

|

3000

|

3000

|

5000

|

10000

|

|

Temperature range of inlet air

|

℃

|

40℃ ~ 300℃

|

30℃ ~ 300℃

|

30℃ ~ 300℃

|

140°C ~ 300°C Adjustable

|

50°C ~ 300°C

|

|

Temperature range of outlet air

|

℃

|

40℃ ~ 140℃

|

30℃ ~ 140℃

|

30℃ ~ 140℃

|

80°C ~ 90°C

|

30°C ~ 150°C

|

|

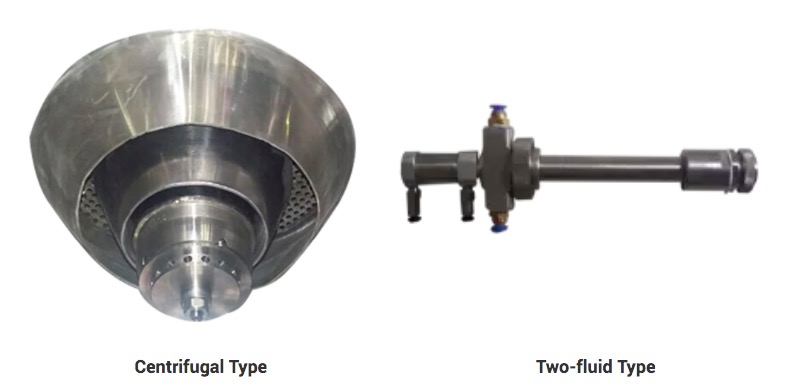

Spray system

|

/

|

Two-fluid nozzle

|

Two-fluid nozzle

|

Centrifugal nozzle

|

Centrifugal nozzle

|

Centrifugal nozzle

|

|

Precision of temp

|

℃

|

±1

|

|

Dryer time

|

S

|

1.0 ~ 1.5

|

|

Speed of squirt pump

|

ml/h

|

50 ~ 2000

|

3000

|

3000

|

5000

|

10000

|

|

Nozzle size

|

mm

|

0.5/0.7/0.75/1.0/1.5/2.0

|

/

|

|

Spray direction

|

/

|

Downwards co-current

|

|

Heater Power

|

/

|

3KW 108V-240V

|

|

Total power

|

/

|

10KW 380V

|

|

Heat source

|

/

|

Electric

|

|

Air compressor

|

/

|

Built-in oil-free air compressor

|

|

Dried powder restoring rate

|

%

|

≥95

|

≥98

|

|

Dimension

|

mm

|

940*850*

1500

|

1700*1100*

150

|

1700*1100*

150

|

1800*930*

2200

|

2500*1600*

2800

|

|

Maximum moisture evaporation

|

Kg/h

|

2

|

3

|

3

|

5

|

10

|

1.Stainless steel material, arc corner design and polyester powder coated shell, prevents corrosion of acidity and alkaline air effectively.

2. Imported Schneider electrical components which is more stability.

3. PLC control system, make your research more easier and efficient.

4. Build in oil-free air compressor, without any noise.

5. Self-priming peristaltic pump, avoid secondary pollution, make sure whole process conducted steady and smoothly.

6. Narrow size distribution, more than 95% of the dry powders are in the same range of particles.

7. Innovative tower wall purging device, improves the material recycling rate.

8. High speed of drying, after spraying of the material liquid, the surface area of material will be increased greatly, make your research more efficient.

9. In the hot-air flow, 95%~98% of water can be evaporated at a moment. You can finish material drying only in several seconds.

10. Especially suitable for drying the heat sensitive materials, after drying, there's no need for smashing and sorting, so as to reduce the operation procedures and save your time.

1.Beverages, Flavours and Colouring, Milk and Egg Products, Plant and Vegetable Extracts, Pharmaceuticals, Heat sensitive Materials, Plastics, Polymers and Resins, Perfumes, Ceramics and Advanced Materials, Soaps and Detergents, Blood, dyestuffs.

1.Beverages, Flavours and Colouring, Milk and Egg Products, Plant and Vegetable Extracts, Pharmaceuticals, Heat sensitive Materials, Plastics, Polymers and Resins, Perfumes, Ceramics and Advanced Materials, Soaps and Detergents, Blood, dyestuffs.

2.Most solutions and supernsions can be spray dried providing.

3.Food, biology, material, pharmacy, university, and R&D institute.

4.Food Stuffs, Adhesives, Oxides, Textiles, Bones, Teeth and Tooth Amalgan and many others.

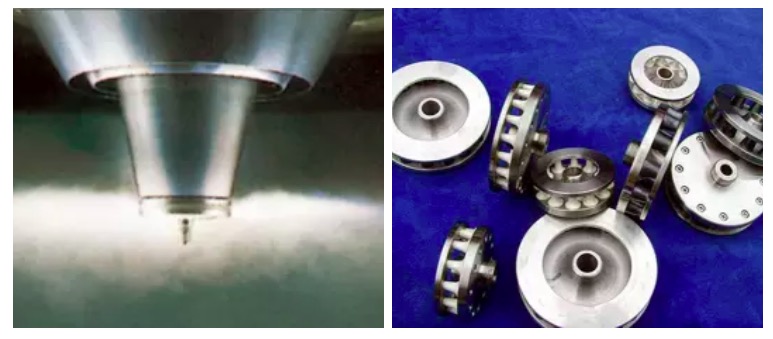

Air through filtering and heating, enter the hot air distributor which is at the top of spray dryer, hot air spiraling evenly into the drying chamber. Liquid through the high-speed centrifugal automizer which is at the top of drying chamber, (rotating) centrifugal spray into tiny fog droplet, then contact with the hot air flow, drying finish product in a very short time and whereabouts. Finished product output continuously between the drying tower bottom and cyclone separator, exhaust through dust catcher emptying by induced draft fan.

Drying effection