Laboratory Jar Roll Ball Mill Ultrafine Grinding And Mixing

Product Description

Jar mill is a kind of equipment used for ultrafine grinding and mixing for laboratory and small batch production, which is also called rolling machine altar. The machine is preferred equipment for scientific research, teaching, experiment and production due to its advantages such as beautiful design,compact structure, easy operation, high efficiency, and uniform granularity. It is widely applied to industries of electronic material, magnetic material, biological medicine, ceramic glaze, metal powder, nonmetallic minerals, new materials and etc. Optimal design of rotating speed is adopted in the machine, where mill jar is dragged to rotate by rubber roller, balls inside the jar make incline flow movement and disperse materials, thus it obtains best effects of grinding. As result, materials are grinded to micron powder. Timing control panel is adopted in the machine with controlling functions of pausing and cumulative timing, and you may set working time according to requirement at any time. It saves time and labor, and is easy for operating.

Principle

When ball mill works, the grinding media and the materials of the cylinder are rotated to a certain height. Due to the gravity, they fall down from the tube wall. The materials are crushed by impact action of the grinding media, and friction and shearing action of grinding media's rolling and sliding. The final granularity can be amounted to 5μm-13μm .

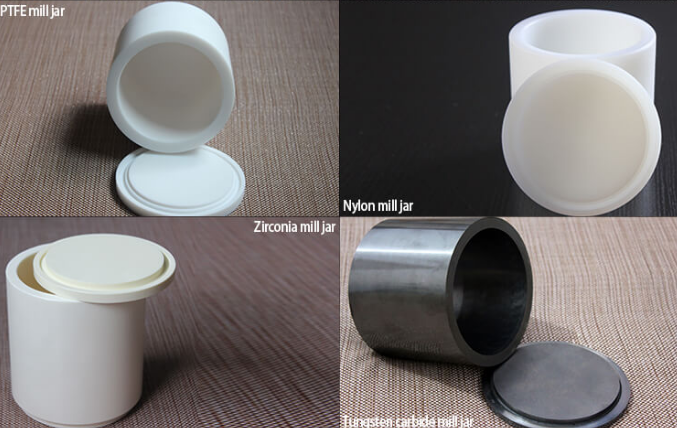

Matched Accessory - Mill Pots and Mill Balls

Besides the ball mill machine, our factory provides all kinds of mill pots stainless steel pot, zirconia pot, alumina pot, nylon pot, PU pot, tungsten pot, hard metal pot tempered nylon pot etc. Further, we also provide stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, etc.

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.