Touch Screen Programmable (1-200 Mm/Min) Dip Coater With Drying Oven Up To 100°C

Specifications:

|

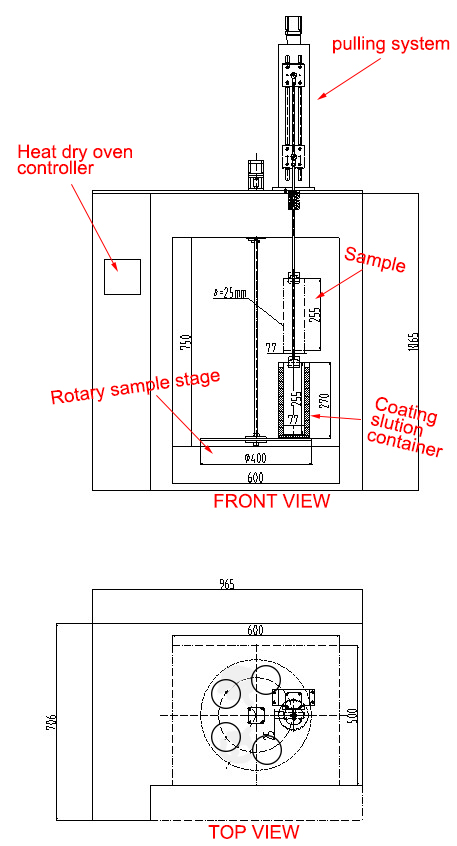

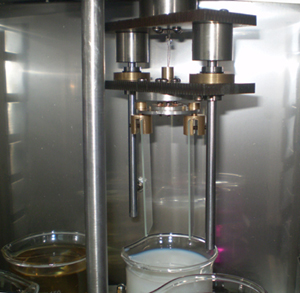

Structure

|

· 5 positions programmable rotary stage

· stepping motor control pulling system with control resolution as low as 1mm/min

· Stainless steel pulling wire

· quick sample clip for up to 10" x 3" sample

· Stainless steel oven chamber

|

|

Rotary dipping stage

|

The rotary dipping stage has five slots to place coating solution containers. It is controlled by the program to send each container sequentially in position for sample coating. According to the program which user can coat their sample with one or multiple layers of coating at one go.

|

|

Touch screen controller

|

6" color touch screen controller

|

|

Travelling Distance

|

300 mm max.

|

|

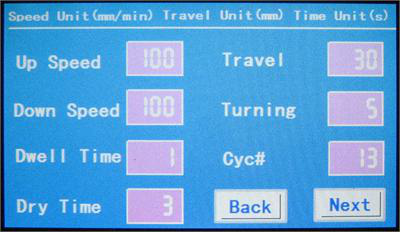

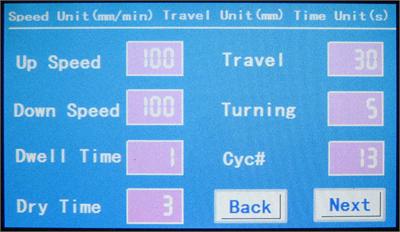

Dipping/Pulling Speed

|

1-200 mm/min Adjustable

|

|

Max. Working Temperature

|

200°C (+/- 1.5°C accuracy)

|

|

Max. Sample Size

|

10" x 3"

|

|

Max. Sample Weight

|

4 kg

|

|

Dipping/Pulling Motor

|

Stepping Motor

|

|

Oven

|

· Working Voltage: 208-240V AC

· Max. Power Consumption: 2300W

· Inside dimensions: 600 x 500 x 750mm (L W H) ( 225L)

|

|

Compliance

|

CE Certified

|

|

Warranty

|

One year limited with lifetime support

|

|

Application Notes

|

· In order to get better film coating, the substrate shall be treated by plasma cleaner

· Use ultrasonic processor to disperse nanopowder or homogenize solution to get better coating

|

|

Net Weight

|

100 kg (220lbs)

|

|

Shipping Dimensions

|

40"(L) x 40"(W) x 60"(H)

|

|

Shipping Weight

|

182 kg (400 lbs)

|

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.