liquid desiccant air conditioning unit can be reduced by 50% to 60%. and the sterilization rate reaches 92-95%.

Min.humidity<2.0g/kg

Total heat recovery efficiency ≥65%

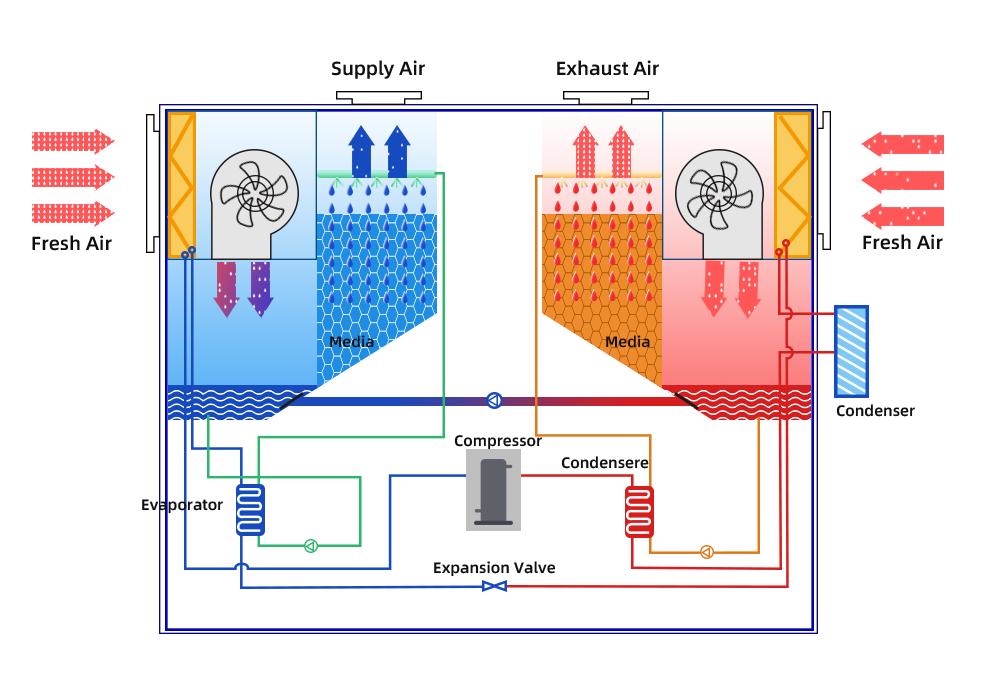

Introduction

The total heat recovery type fresh air unit is mainly used for the fresh air treatment of office scientific research buildings, transportation hubs, museums, science and technology museums, hotels, apartments, hospitals, and industrial plants, especially for the fresh air treatment of air conditioning systems with independent temperature and humidity adjustment.

Applicable Condition

◆ ambient temperature:-10°C-45°C.

◆ Minimum air humidity:2g/kg.

Advantages

1) Easy installation and convenient maintenance.

2) International quality, reliable operation.

◆Refrigeration components, control components, pumps and fans and other operating components are all internationally renowned brands with reliable quality.

◆Adopt intelligent control, man-machine interface and standard communication protocol, with stable control and high precision.

◆Complete protection devices, stable and reliable operation.

3) Professional anti-corrosion and anti-rust design, long service life.

◆The heat exchanger is made of titanium tube, which will never rust.

◆ The water tank is made of PP material for injection molding, and the pipeline is designed with soft connection to reduce pipeline nodes and prevent liquid leakage.

4) The solution balancer can be air-cooled and water-cooled, with stronger applicability.

5) City tap water only, without softening water.

Specification:

Model (NTD(V)F口口)

|

03B |

06B |

09B |

12B |

15B |

| Power supply |

3PH-380V-50Hz |

| Supply airflow m³/h |

1000 |

2000 |

3000 |

4000 |

5000 |

| Exhuast airflow m³/h |

1200 |

2000 |

3600 |

4800 |

6000 |

| Cooling capacity KW |

7.2 |

14.4 |

21.6 |

28.8 |

36 |

| Dehumidifying capacity kg/h |

5.4 |

10.8 |

16.2 |

21.6 |

27 |

| Rated power kw |

3.1 |

5.8 |

9.2 |

12 |

15.5 |

| Noise dB(A) |

60 |

61 |

62 |

63 |

64 |

| Compressor type |

Fully closed scroll compressor |

| Throttle |

Thermal expansion valve |

| Cryogen |

R407C |

| Fan type |

Outer rotor centrifugal fan |

| Pre-filter grade |

Primary (G4) |

| Supply air pressure Pa |

130 |

280 |

300 |

330 |

350 |

| Exhaust air pressure Pa |

130 |

240 |

250 |

260 |

270 |

| Weight Pa |

660 |

1050 |

1600 |

1850 |

2200 |

Note:

① Nominal working condition: fresh air dry bulb temperature 36°C,RH 65%,return air dry bulb temperature 26°C, RH40%;supply air dry bulb temperature 16°C RH 35%.

② Please contact our company for different working conditions.

③ Tap water can be used as supply water,no softened water is needed.

④ The fan can be customized or installed with a frequency converter according to the customer's residual pressure requirements.

③ For non-standard units,please contact us.

Characteristics:

Different Dehumidification Methods in Air Handling Process

Comparison and Power Consumption Analysis of Several Dehumidification Products

Energy Consumption Analysis of Rotary Dehumidification

Requires high-grade heat to heat air for regeneration, and the

ehumidified air needs to be cooled via refrigeration to reach the supply

air state point, resulting in extremely high energy consumption.

Four Major Problems of Rotary Dehumidifiers:

1.Regeneration requires temperatures over 100°C, leading to high

heating energy consumption.

2.The dehumidified air has a high temperature and requires cooling, adding

significant additional refrigeration energy consumption.

3.The desiccant wheel is prone to clogging, necessitating frequent cleaning

and maintenance.

4.The wheel undergoes large temperature variations, making it susceptible to aging and noticeable efficiency degradation.

Refrigeration Dehumidification Energy Consumption Analysis

Moisture is removed by cooling air to low dew-point temperatures for condensation dehumidification. The air must then be reheated to reach the supply air state point, resulting in very high energy consumption.

Three Major Drawbacks of Refrigeration Dehumidification:

1.Low operating temperatures during dehumidification significantly reduce compressor efficiency;

2.Energy waste through mandatory reheating processes;

3.Condensate water generation creates mold growth risks and other hygiene hazards.

Analysis of Liquid Desiccant Dehumidification Energy Consumption

The liquid desiccant absorbs moisture from air in the medium-high temperature range. Air temperature is maintained near ambient room temperature without reheating or recooling consumption, resulting in low energy consumption.

Six Major Advantages of Liquid Desiccant Dehumidification:

1.Rapid and deep dehumidification with moisture removal capacity down to 2 g/kg;

2.Waste heat recovery from heat pump condensers for solution regeneration, enabling dual cooling output through integrated dehumidification;

3.Operation above dew point temperature maintains high compressor efficiency;

4.Post-dehumidification air temperature approaches supply air point, eliminating energy offset for reheating/recooling;

5.Inherent antimicrobial properties of salt solutions ensure higher air quality;

6.Winter humidification capability via four-way valve reversal (using wet media), offering superior energy efficiency over electrode humidification.

This project is applied to comprehensive hospitals

1.Use area 1000㎡

2.Adopt AHLD-N9A(N) equipment

3.The total air volume is 5800m³/h

4.Outdoor working condition is 37℃/65%

5.Indoor working condition is 25℃/60%

6.Solution dehumidification equipment bears the entire indoor humidity load and part of the cooling load. Main cooling load is still provided by the indoor refrigeration equipment.

This Project: Chocolate factory in Singapore

Air treatment type: Fresh air dehumidification treatment

Area: 10000m2

Outdoor working condition: 35 ° C DB/30 ° C WB,70%RH

Indoor working conditions: < 40%RH

The air supply temperature of the equipment is 22℃, the relative humidity is 40%, the abslute humi. is 6.5/kg, the dehumidifier is 296.8kg/h, the cooling capacity is 270.5kW, and the equipment power is 80.6kW.

The Project Name:MERCK Pharmaceuticals, Singapore

Air treatment type:

Fresh air humidity, temperature independent treatment

Area: 3000m2 Outdoor working condition: 29℃DB/89%RH

Indoor working conditions: 20-25℃DB/54%RH

Equipment: AHLD-N09B , Airflow: 3000m³/h, 15 sets

Rated cooling capacity: 28kW,

Dehumidification capacity: 32.8kg/h, Rated power: 9.2kW

Operating condition: This project was put into operation in the spring of 2013. After adaptive debugging, it is in good condition and can meet the indoor temperature and humidity requirements

The Project Name:Plant seedling laboratory

Use area: 315m2 Outdoor working condition: 35.6℃DB/27.9℃WB;

Indoor working conditions: bright stage 22℃DB/60%RH, dark stage 15℃DB/90%RH

Equipment: AHLD-DF18N,Airflow: 18000m³/h, 2 sets

The rated cooling capacity of the equipment is 150kW, Dehumidification capacity: 108kg/h,Installed power: 75kW

Operating condition: This project was put into trial operation in the autumn of 2021. After multi-season adaptive debugging and adjustment, it can meet the indoor temperature and humidity requirements.

More advantages:

1.Supply air temperature is suitable, without reheating problem of freezing dehumidification and recooling problem of rotary wheel dehumidification.

2. Dehumidification above the dew point, avoiding the possibility of bacterial growth in the condensate pan affecting air quality.

3.Halite solution has a sterilizing and purifying effect on air, improving air quality.

4.Air supply and exhaust air flow through different ducts, without the risk of leakage bettween supply air and exhaust air of rotary wheel dehumidification .

5.Humidity treatment range is wide, can be as low as about 20%.

6. Solution regeneration temperature is low, can utilize condensation heat or low-temperature natural heat source, energy-saving and environmentally friendly.

7. Solution system maintenance is simple, usually only need to clean the filter.