Patented Design of Automatic Plate Alignment For Letterpress Intermittent Printing Machine

-

Enables automatic chromatography before the machine begins printing to reduce material wastage and machine adjustment time.

-

Achieves accurate stop/start chromatography at high rev. Speed by automatically locking the screw rod with the controller system following the completion of automatic chromatography at the printing station; there is no need for manual adjustment when restarting the machine following stoppage, at which time the system automatically calculates the time for acceleration and cushioning based on the preset speed and adjusts the tension for accurate positioning. Throughout the entire process, wastage limited to only one meter of raw material.

-

Free of the need for further fastening with a locking handle, at this moment avoiding damage to the equipment when the handle is locked or effects on chromatography caused by manual locking.

Application for Letterpress Printing Machine

Art paper, Mirror coat paper, Foil paper, PET, PVC, PP, PE, Electrostatic paper, Laser Film, Flocking paper, Binding cloth, Textile, Cardboard, Kraft, Crepe paper, Polar Film, Silver reflect Film, Laminate copper foil, Photoelectric Film, Conductor Film, Soft PC plate, LCD Conductor glue, Shockproof glue, High Tec. The laminate material, EMI insulator, Sponge rubber ..... etc. Generally Speaking, all the printing materials just not too shrinkable or stretchable can be printed by this machine.

Specifications for Intermittent Rotary Letterpress Printing Machine

Max. web width : 350 mm

Max. Printing Area

Full Rotary: 340(w)*376(L)

Intermittent Rotary: 50~305(L) x 270(w)

Max. Speed: 30-200 RPM, 0 ~ 12000 imp / hr

Power supply: 3 phase, 80 A, 15 kW

Machine weight: 3500 KG (N.W.), 4500 KG (G.W.)

Mechanical installation dimensions: L 550 x W 120 x H 140 (CM)

Standard Features for the Letterpress Label Printing machine :

-

Transformer

-

Tension Rewinding Device

-

Screen Roller (6 rollers)

-

UV Dryer ( 6 stations)

-

2nd Pass Scanner Unit

-

Printing Plate Setting Station

-

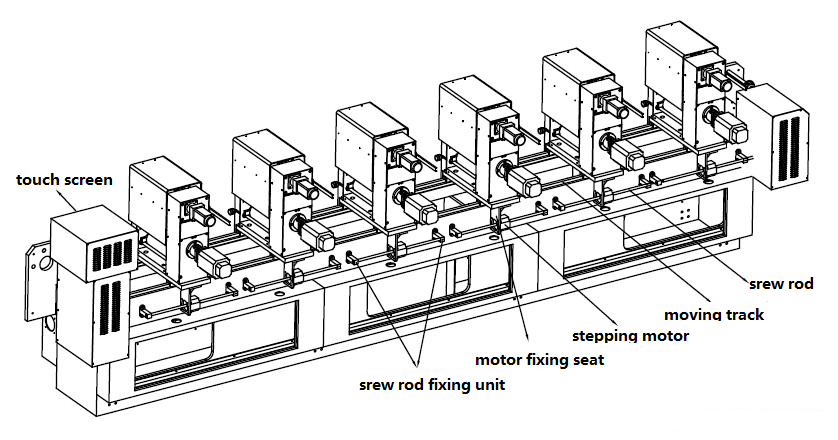

Auto. Registration Device ( 6 stations)

-

Micro-adjustment positioning Unit ( 6 stations )

-

Web Guiding Feeder ( Device Import from Italy )

-

UV Center Control Case, Including Exhausting System

-

Ink Roller ( six stations, Including Ghost Shadow Erasing Roller )

Option Functions For different clients

-

Corona Device

-

Round Knife Die-cut Seat

-

Flexo Varnish Station (exclusive printing station )

-

Laminating Rewinder

-

CCD Registration Station ( high precision guarantee )

-

Electrostatic Eliminator

-

Slitter & Rewinder

-

Back Printing Station

-

Cold-stamping Station

-

Rewinding Machine (with web guiding system )

-

Flat Press die -cutting

Characteristics for Letterpress Full / Intermittent Rotary Printing Machine

-

Machine body casting molding, CNC machining center completed one body integrated molding,

-

permanent non-deformation, to ensure the durability of the structure and printing stability.

-

Full-servo printing control system, ensure high running accuracy.

-

Removable stencils, change it faster.

-

Adopt the left-right sway ink wheel to stir ink evenly eliminating printing overlap ghosts.

-

Unilateral fine-tuning press device saves time and effort.

-

The printing station can close when not using to reduce the wear of the roller.

-

Japan imported anilox roller to ensure the high quality of ink.

-

A set of stencils can be printed multiple sizes, saving the printing cost.

-

The ink release system can control each color station separately through the touch panel.

-

Automatic ink discharge and manual ink discharge can be selected.

-

Automatic Plate Alignment can entirely save materials wastage and adjust machine time, no need to manually fix the color seat; the system will automatically enter the locked state after changing.

-

Automatic ink applies unit: The system automatically adjusts the tension and amount of ink under different printing speed ensuring accurate alignment and the same printing quality.

-

Second printing device to meet customer's repeated printing process.