Lithium Battery Precision Extrusion Coating Machine

Prosuct Specification

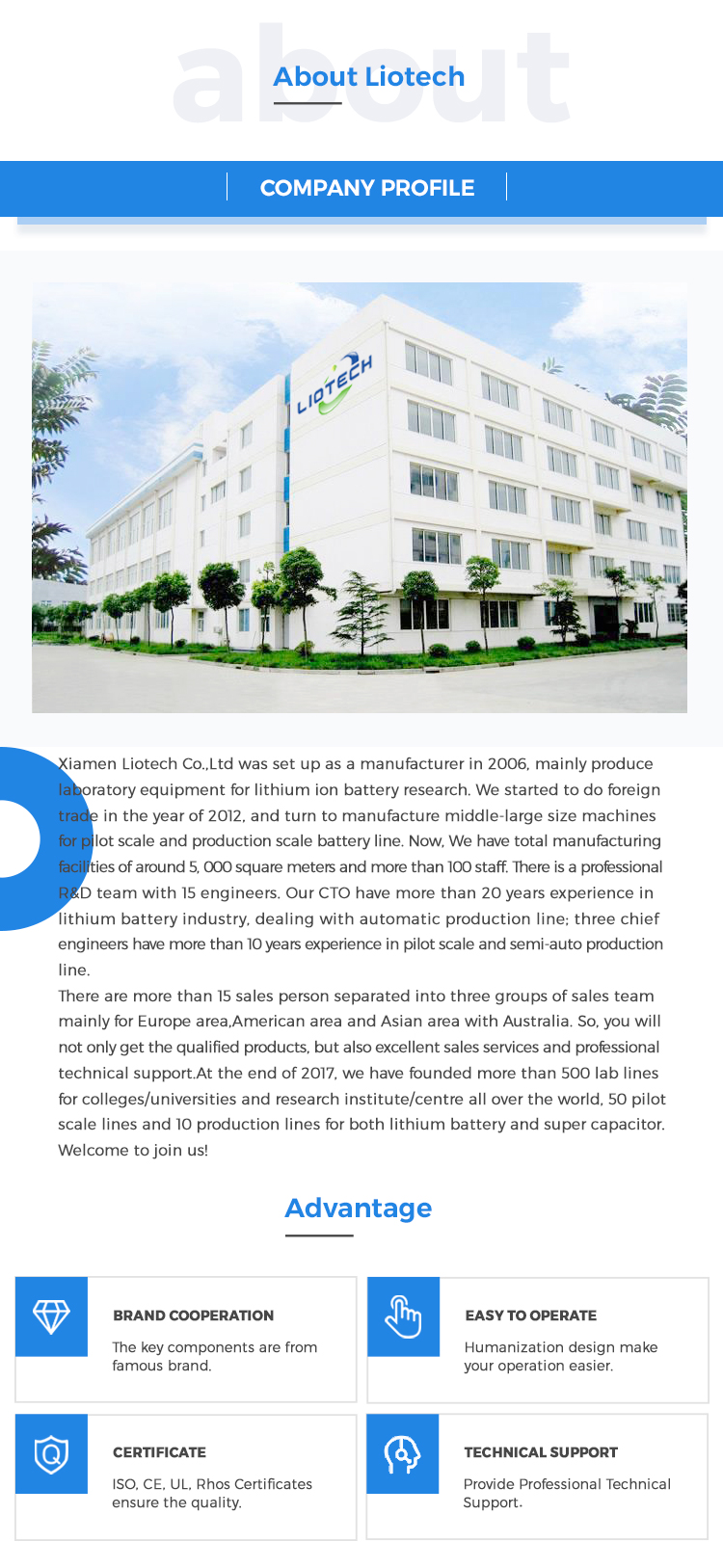

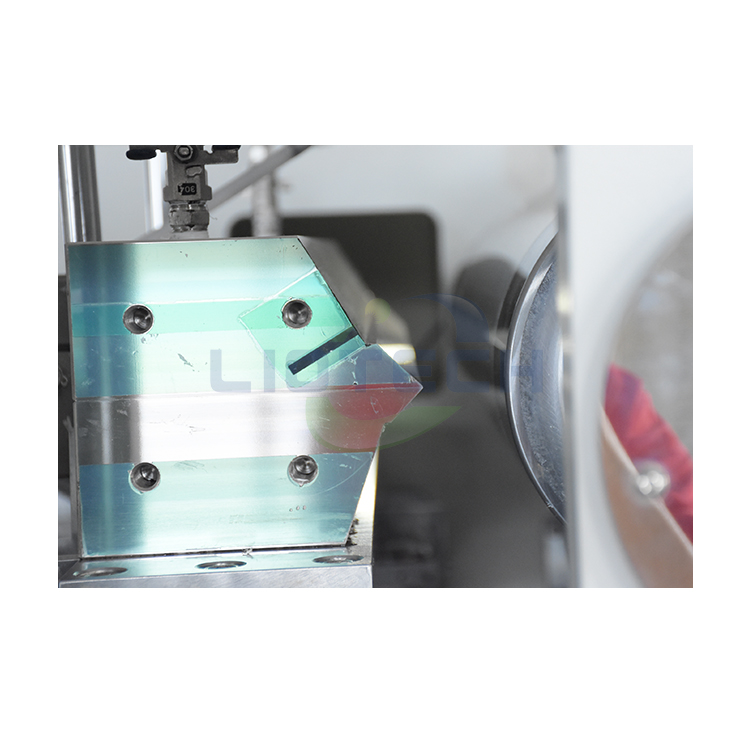

The electrode substrate mounted on the unwinding device enters the unwinding tension system after automatic deviation correction. After adjusting the unwinding tension, it enters the coating head. The electrode is coated according to the setting procedure of the coating system. After coating the wet electrode into the oven by hot air drying. The dry electrode is adjusted by the tension system, and the winding speed is controlled to keep it in sync with the coating speed. The electrode is kept in the set position by the automatic rectifying system, and the rewinding device is used to rewind the chip.

|

Basic parameters of the substrate

|

|

|

cathode substrate

|

anode substrate

|

|

Name

|

Copper foil

|

Aluminum foil

|

|

Thickness

|

(6-30) μm

|

(10-30) μm

|

|

Width

|

(300-600) mm

|

(300-600) mm

|

|

Coating parameters

|

|

Materials Name

|

Cathode slurry

|

Anode slurry

|

|

Graphite,intermediate carbon,hard carbon etc.

|

LCO,NMC,LMO,LFP etc.

|

|

Dry thickness

|

(50-150) μm

excluding foil single dry

|

(50-150) μm

excluding foil single dry

|

|

Wet thickness

|

100μm~500μm

|

100μm~500μm

|

|

Solid content

|

(40-70) ±5%

|

(30-80) ±5%

|

|

Proportion

|

(1.0-1.4) g/cm3

|

(1.0-2.5) g/cm3

|

|

Viscosity

|

(3000-5000) CPS

|

(5000-12000) CPS

|

|

Temperature

|

According to the process to control the RT ~ 140 ℃, using electric heating mode

|

|

Solvent

|

NMP oil/water system

|

NMP oil/water system

|

|

Basic parameters of the machine

|

|

Width of coating roller

|

700 mm

|

|

Effective coating width

|

500mm and below

|

|

Coating method

|

continuous extrusion coating/intermittent extrusion coating

|

|

Coating speed of dressing

|

≤8m/min (related to paste state and coating process setting)

|

|

Power

|

380 V x 50 Hz, 3 phases (control power supply 220 V x 50 Hz, single phase)

|

|

Total power

|

maximum 150KW

|

|

Air source

|

0.6 MPa

|

|

Total machine length: no more than 32 meters (excluding thickness measurement system)

|

|

Safety requirement

|

Meet relevant national standards

|

|

Dry part parameters

|

|

Number of temperature control areas

|

6 knots

|

|

Total oven length

|

18+0.6 (300 mm negative pressure chamber at head and tail) =18.6 m

|

|

Heat source

|

Electrical heating

|

|

Temperature

|

MAX: 140℃

|

|

Oven surface temperature

|

the temperature is not more than 50 ℃ (excluding oven door)

|

Images

Packing