Click To View Video

(Running In “RADHE PACKAGING” India)

Product Name:

Model ZYKM II High Speed Full Automatic Printing Slotting Die Cutting Machine

Overall Machine Performances

●This machine is made in line with European concepts featuring reliable function and safety, and CE certification is issued;

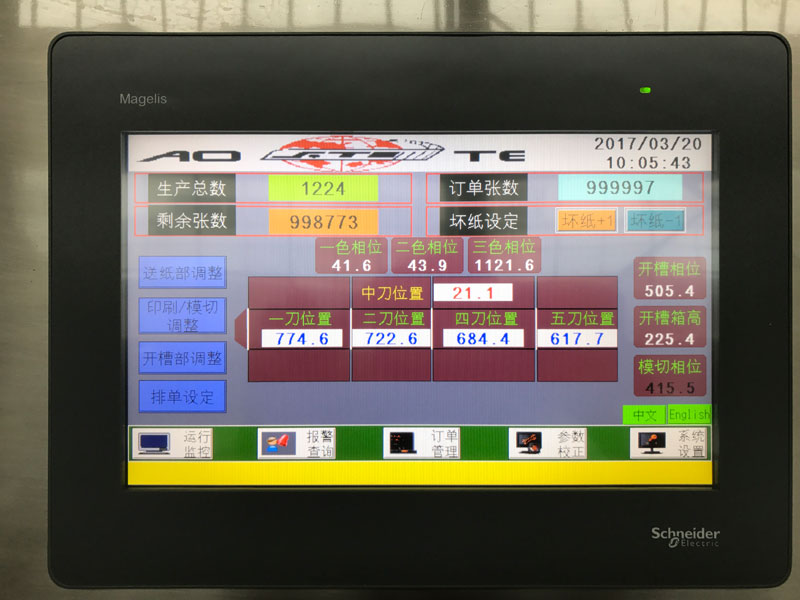

● In automatic control system, merely an order of box size information is input on touch screen, all the cylinders clearances, axial and circumference data of feeder, printer, slotter and die cutter will be set automatically featuring accuracy and reliability without personal interference to realize full automation and enhance production efficiency;

●Full auto production control system of CNC (Computer Numerical Control) stores and quickly changes production orders, featuring fast order change and simple operation;

●Imported transmission gears are adopted which are hardened and ground with > 60o Rockwell hardness;

●Bearings are imported from Japan;

●All transmission rollers are made of top quality steel processed through dynamic/static balance tests, chrome plating and polishing;

●All the main electric control devices are purchased from SCHNEIDER France and OMRON Japan and others well-known suppliers;

●10 inches HD color touch screen is imported from Schneider France in clear display and easy operation;

●Entire machine is equipped with special stainless steel shield in beautiful appearance, easy cleaning and .never rust;

●Spline free joint ring is applied to reduce central wear and maintain long-term accurate overprinting.

Feeder

●Wheel lead edge feeder features accurate feeding, little vibration, long service life and easy maintenance;

●High feeding accuracy and adaptable blank caliper is between1.5mm-10mm;

●The mechanical vibration can be eliminated basically to meet the requirements of working accuracy to minimize the error from the clearances in the process of pull rollers running;

●Left/right raffles are set electrically and a side squaring device is installed.

●Cleaning brushes remove dust on blank surface to improve printing quality.

●Upper suction fan removes dust particles on blank to make it cleaner.

Printer

●It is made of quality steel with professional workmanship through strict dynamic/static balance tests, chrome plating after grounding and then polishing to secure the smooth running and delicate printing;

●Ratchet fixed plate-reeling shaft and full page slot of printing plate mounting are suitable for easy plate mounting of 10mm plate hanging strip;

●Touch screen controls printing cylinder forward or backward circularly at 360o (frequency inversion and dual speeds);

●Printing cylinder axial shifting is set electrically on touch screen at ±10mm setting value in digital indication;

* The last color printer is added with pre-creasing wheel to prevent blanks from crushing in the process of creasing;

●An automatic cleaning device is able to let ink recycled and cleaning easier and faster.

Slotter

●Automatic

production management system can fulfill the settings of axial direction and

phase of feeder and printers, settings of box height, phase, circularity and

axial shifting, and diecutter automatically in case all the data of orders are

entered into touch screen without any human interference featuring accuracy and

reliability. Coupled with transmission spindle, the top/bottom knives are well

aligned to prolong their durability;

●The man-machine interface alarm prompts and displays equipment abnormal

situation, so as to eliminate the abnormal phenomenon;

●A

collision proof protector is installed to prevent it from damaging;

●Slotting

knife is indented blade of 7mm width, which is made of alloy steel through

thermal treatment and grinding featuring sound hardness and tenacity. The

trimming knife is made of steel alloy is under thermal treating, grinding and

sharpening featuring sharp blade and more accuracy.

●Elastic

angle cutting design is able to cut off sing-wall and double wall corrugated

boards easily without setting, boasting the simple operation;

●Upper

creasing wheels are wrapped with PU coverings to protect blanks;

Die-cutter

●The phase and axial settings of die cutting cylinder can be done on touch screen, which is electrically set and digitally controlled;

●The setting of diecutter cylinder left and right shifting is done on touch screen in electrical setting and digital control within 10mm setting range;

●Anvil cylinder is made of quality steel through precise machining, dynamic/static balance tests;

●Anvil cylinder adopts trimming system to make the covering flat, even and smooth to improve its life and reduce costs;

●An interlocking press button is fixed in diecutter to realize emergent stop, conveying stop and resuming blank feeding;

Auto Stacker

1. Auto/manual control modes available;

The tension of conveying belt of sheet collecting arm can be set separately without the limit by belt length featuring easiness, flexibility and quickness.

2. Collector Bed Elevation

(1) Driven by a strong chain for smooth elevation and transverse movement;

(2) 1600mm stacking height;

(3) Collecting bed elevation motor is attached with a brake to remain it at a fixed position without sliding down.

3. Collection Baffle

(1) Collecting plate is driven pneumatically and the stacking height is control by photocell;

(2) Back baffle can be set manually in line with blank length;

(3) The grained surface belt shows fine friction to prevent it from slipping.

Technical Parameter

|

Technical Data

|

900x2000

|

1200x2000

1200x2400

|

1300x2500

|

1600x2400

1600x2800

|

|

Max Mechanical speed(p/min)

|

250

|

200

|

200

|

140

|

|

Max feeding size(mm)

|

900x2000

|

1200x2000

1200x2400

|

1300x2500

|

1600x2400

1600x2800

|

|

Min feeding size(mm)

|

320x650

|

320x650

|

350x685

|

400x750

|

|

Skip feeding size(mm)

|

1100x1900

|

1400x1900

1400x2300

|

1500x2400

|

1800x2400

1800x2800

|

|

Max printing area(mm)

|

850x1900

|

1200x1900

1200x2300

|

1300x2400

|

1600x2300

1600x2700

|

|

Standard plate caliper(mm)

|

7.2

|

7.2

|

7.2

|

7.2

|

|

Min slotting distance(mm)

|

Forward

|

160x160x160x160

|

160x160x160x160

|

160x160x160x160

|

160x160x160x160

|

|

backward

|

250x60x250x60

|

250x60x250x60

|

250x60x250x60

|

250x60x250x60

|

|

Max slot

|

300

|

400

|

400

|

400

|

Specifications are subject to change without prior notice in technical requirements