Click To View Video

(ZYKM II 2000x4700mm Running In ‘CARTONESA S.A. DE C.V.’ Salvador)

Product Name:

Model ZYKM II High Speed Full Automatic Printing Slotting Die Cutting Machine

Overall Machine Performances

●This machine is made in line with European concepts featuring reliability, function and safety, and CE certification, issued;

●It is especially designed for jumbo boxes, all the machine is electrically set without any manual operation, and therefore, the printing accuracy, productivity and efficiency are more prominent after setting;

●PLC touch screen control includes the functions of indications of auto counting, speed, production amount, skip feeding and alarms;

●The phase adjustment adopts the original Korean digital dial disk control and it can be set from the current value to target value once in high precision;

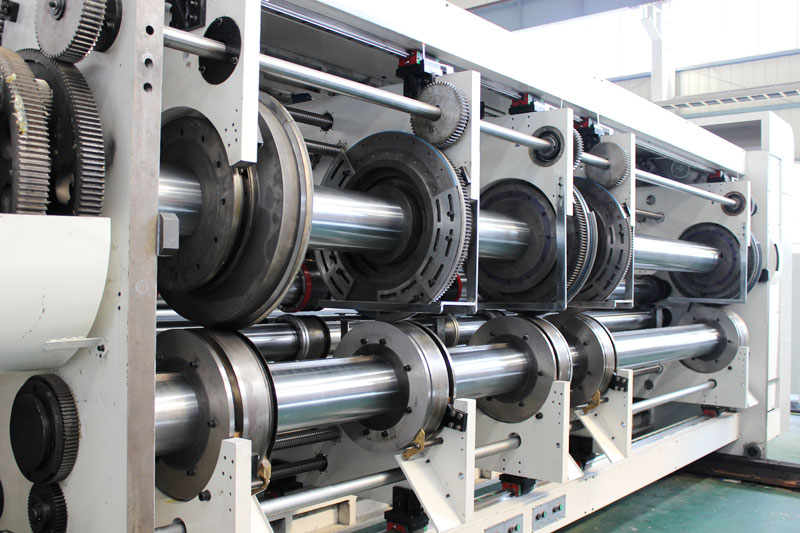

●Imported transmission gears are adopted, which are hardened and ground in >60o Rockwell hardness;

●Main bearings from NSK Japan are used;

●Main electric components are purchased from the suppliers such as DELTA from Taiwan, SCHNEIDER from France and OMRON from Japan;

●Spline free joint ring is employed to reduce center abrasion and remain precise registration for a long time;

Feeder

●Wheel lead edge feeder increases fan airflow to make the feeding more precise at both high or low speed;

●Frequency inverter controls vacuum airflow and pressure to let it adapt to blank size;

●Measures taken to make the positioning from front part of feeder to reduce feeding error and improve feeding, slotting and diecutting accuracies; moreover, it remains more stable in high speed production;

●Left/right baffles are electrical controlled;

●The front/back positions of trail blank support are controlled electrically to facilitate feeding size setting;

●Front baffle is set electrically;

●PLC touch screen control includes the functions of auto counting, speed, yield, skip feeding and alarms etc.

●Upper suction fan removes dust particles on blank to make it cleaner

Printer

●Printing phase adopts dual speed electrical setting;

●Printing phase settings is done with original Korean CNC meter to set from the current value to target value in one step and CNC control values are also displayed;

●Electric axial settings and digital indication are employed at 360 degrees phase for ±10mm axial setting range;

● Printing plate cylinder axial shifting is electrically set at ±10mmsetting values, which are shown on digital meter to facilitate plate alignment;

●Pre-impressing wheel is added in the last color printing to avoid blanks crushed in the process of creasing.

Slotter

●Slotting phase setting adopts original Korean CNC meter to set from the current value to target value in one operation and the digital control and indication are available to let the setting even more quick and easy;

●Slotted box height setting is done with five-knife electrically. A collision proof protector is installed in slotter boss to prevent it from damaging;

●Upper/bottom slotting shafts are set electrically and synchronously with transmission shaft coupling to guarantee upper/bottom knives aligned and prolong their service life;

●The clearance of slotting bosses are set electrically;

●Slotting knife width is 10mm to be especially designed for jumbo boxes of triple-wall corrugated boxes, which is indented blade made of alloy steel through thermal treatment and grinding featuring sound hardness and tenacity. The steel alloy is under thermal treating, grinding and sharpening featuring sharp blade and more precision;

●Elastic angle cutter design is able to cut off single-wall, double wall and triple wall boards easily without any setting, boasting the simple operation;

●Upper creasing wheels are wrapped with PU coverings to protect blanks.

Die-cutter

●Diecutter cylinder is made of quality steel through precise machining, strict dynamic and static balance tests featuring sound running and accurate diecutting;

●Diecutter fastening screw-hole distances: axial: 50mm; radial: 20 divisions in proportion;

●Diecutter cylinder phase is set with dual speed electrical digital settings and planetary gearing at 360 degrees (available at either running or stop);

●Diecutter cylinder left and right shifting is set electrically within 10mm setting range;

●It is made of quality steel through precise machining, dynamic/static balance tests;

●Anvil cylinder is equipped with tracer and differential compensation device to control the anvil cylinder speed within ±3mm compensation range;

●Anvil cylinder adopts trimming system to make the covering flat to prolong its service life.

Auto stacker

1. Auto/manual control modes available;

The tension of conveying belt of sheet collecting arm can be set separately without the limit by belt length featuring easiness, flexibility and quickness.

2. Collector Bed Elevation

1) Driven by a strong chain for smooth elevation and transverse movement;

2) 1600mm stacking height;

3) Collecting bed elevation motor is attached with a brake to remain it at a fixed position without sliding down.

3. Collection Baffle

1) Collecting plate is driven pneumatically and the stacking height is control by photocell;

2) Back baffle can be set manually in line with blank length;

3) The grained surface belt shows fine friction to prevent it from slipping.

Technical Parameter

|

Technical Data

|

2500x3600

|

2000x4700

|

|

Max machine speed(p/min)

|

60

|

60

|

|

Max feeding size(mm)

|

2500x3600

|

2000x4700

|

|

Min feeding size(mm)

|

400x720

|

400x720

|

|

Skip feeding(mm)

|

2700x3500

|

2200x4600

|

|

Max printing area(mm)

|

2500x3500

|

2000x4600

|

|

Printing plate thickness(mm)

|

7.0

|

7.0

|

|

Paperboard thickness(mm)

|

2.0-12

|

2.0-12

|

Specifications are subject to change without prior notice in technical requirements