Apart from those warehouse solution allowing direct access to each pallet (as seen in our section "unit load ASRS"), multi-deep pallet storage systems are another important group of solutions used for warehouse environments where there’s a high throughput volume for products that relatively high levels of inventory but limited SKUs .

This group includes solutions with Drive-In/Drive-Thru Rack, Gravity Flow Rack, Radio Shuttle Rack System, Mobile Racking, and Multi Deep Pallet ASRS.

Multi Deep Pallet ASRS are fully automated pallet storage solutions for warehouses with low ceilings, fewer unique products and high throughput requirements, these shuttle based ASRS system range from:

Mother & Baby Shuttle (satellite) System

Four Way Shuttle System

S/R M + Shuttle System

Radio Shuttle System-- Semi Automated Solution

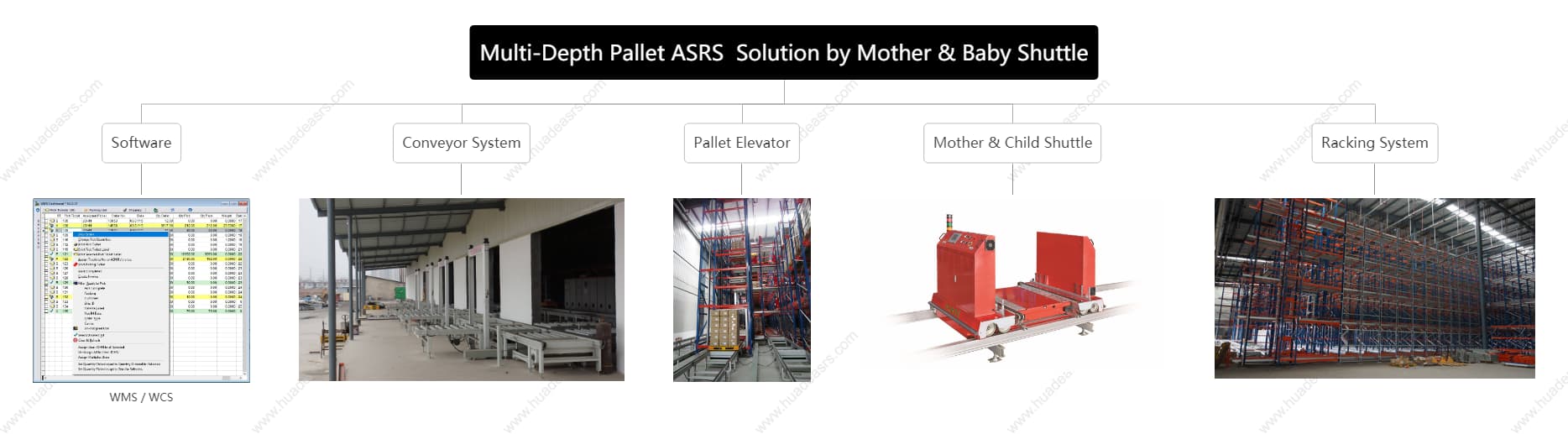

HUAYIDE’s Mother & Baby Shuttle ASRS consists of high-density pallet racking, mother shuttle (satellite) powered by bus bar, baby (child) shuttle board on mother shuttle, pallet elevator, buffer conveyors etc.

How does it works?

Racking system are divided into several racking modules in the proposed area. Each Racking Module has different levels and each of them with a main aisle attached with multiple lanes located on the both sides of aisle for pallets storage.

Mother Shuttle (Satellite / Carrier) runs along the aisle and powered by bus bar at every level, its onboard Child Shuttle (Satellite) is controlled by the Mother Shuttle via WIFI that moves along the lanes for performing pallet storage and retrieval automatically.

The system need to be integrated with vertical lift so that carry pallet to the designated storage level. Once pallet reach to the assigned level, it will be moved to buffer conveyor and wait for mother & baby shuttle pick up. Then Baby shuttle will take the load and get inside the Mother shuttle to again move on the aisle in order to reach the next location. Retrieval of loads also happens through the same process.

The movement of the mother shuttle is automatically controlled by software in an onboard Programmable Logic Controller (PLC) which communicates to the main controller.

HUAYIDE Mother& Baby shuttle also can be operated manually through a touch screen Human Machine Interface (HMI), which allows the operator to verify the current state of the shuttle, modify parameter, etc.

Mother & Child Shuttle systems can be used in a wide range of environments, from -30℃ in frozen food storage to 50℃. The modular design of the HUAYIDE system opens up completely new possibilities for automation in existing warehouses.

Facts:

- Maximum storage capacity up to 80%-90%

- Effectively eliminate error rate by Warehouse Management System

- Allow for expansion as throughput increase without changing original layout

- Ideal solution for manufacturing businesses, especially those in the fast moving consumer goods, food ,beverage and cold chain industries

Specifications:

|

Type

|

Non layer transfer type

|

Layer transfer type

|

|

Mother Shuttle Model

|

HDSZS

|

HDSZM

|

|

Mother Shuttle Power Supply Mode

|

Bus bar

|

battery

|

Bus bar

|

battery

|

|

Max Load Capacity (kg)

|

1500

|

1500

|

1500

|

1500

|

|

Applicable Pallet Size (pallet length mm)

|

1100×1300

|

1100×1300

|

1100×1300

|

1100×1300

|

|

Speed

|

Mother Shuttle empty load

|

2.5

|

1.5

|

2.5

|

1.5

|

|

Mother Shuttle fully load

|

2.0

|

1.0

|

2.0

|

1.0

|

|

Satellite empty load

|

1.0

|

0.9

|

1.0

|

0.9

|

|

Satellite fully load

|

0.6

|

0.5

|

0.6

|

0.5

|

|

Motor power

|

Mother Shuttle drive motor

|

2.2 (AC380V)

|

1.5 (DC48V)

|

2.2 (AC380V)

|

1.5 (DC48V)

|

|

Mother Shuttle chain motor

|

0.4 (AC380V)

|

0.4 (DC48V)

|

0.4 (AC380V)

|

0.4 (DC48V)

|

|

Satellite drive motor

|

0.4

|

0.4

|

0.4

|

0.4

|

|

Satellite lifting motor

|

0.37

|

0.37

|

0.37

|

0.37

|

|

Mother Shuttle battery

|

Battery capacity Ah

|

|

80

|

|

80

|

|

Continuous working hours on a single charge

|

|

8

|

|

8

|

|

Charging time h

|

|

8

|

|

8

|

|

Child Shuttle battery

|

Battery capacity Ah

|

Super capacitor

|

50Ah (DC24V)

|

Super capacitor

|

50Ah (DC24V)

|

|

Carrier & shuttle charging mode

|

On-line

|

On-line

|

On-line

|

On-line

|

|

Control mode

|

Manual, Automatic, On-line

|