Specification of silicon carbide powder:

|

Part No.

|

Particle

|

Purity

(%)

|

SSA

(m2/g)

|

Bulk density

(g/cm3)

|

Density

(g/cm3)

|

Crystal

|

Color

|

|

CP1406P-50N

|

50nm

|

99

|

60

|

0.59

|

3.2

|

cubic

|

green

|

CP1406P-50N

|

100nm

|

99.9

|

30

|

1.2

|

3.2

|

cubic

|

green

|

CP1406P-50N

|

1-3um

|

99.9

|

18

|

1.8

|

3.2

|

cubic

|

green

|

Note: We can supply different size products of silicon carbide powder according to client's requirements.

Beta SiC powder is with high chemical stability, high hardness, high thermal conductivity, low thermal expansion coefficient, wide bandgap, high electron drift velocity, high electron mobility, special resistance temperature characteristics. Silicon carbide powder is also with the properties of anti-wear, excellent performance, high temperature, thermal shock resistance, corrosion resistance, radiation, good semi-conductive characteristics. Silicon carbide powder is widely used in electronics, information, precision processing technology, military, aerospace, advanced refractory materials, special ceramics, advanced grinding materials and reinforcing materials and other fields.

Application of silicon carbide powder:

1. β-SiC is an excellent sintered powder

Silicon carbide powder is wiedly used in advanced structural ceramics, advanced ceramics and refractories market. Beta SiC crystallize in about 1800 ℃ and ceramics sintering temperature is from 2300 ℃ to 2500 ℃. The change process in the β-SiC crystal form will change the volume of the ceramic sintered compact performance play a good role, thereby increasing the overall performance of silicon carbide ceramic toughness and strength. Add β-SiC to boron carbide ceramic product can improve the toughness of the product at the same time lower the sintering temperature.

2. Beta Silicon carbide powder is also a good electronic materials

β-SiC is a semiconductive material. Its anti-corona effect is several times higher than the α-Sic, and Al2O3. Otherwise, SiC is also with good wear resistance, high temperature performance. High purity β-SiC can be made of monocrystalline silicon carbide wafer, excellent electrical conductivity, and thermal conductivity. Use β-SiC to make electronic packaging materials, heaters; heat exchangers, etc. will have high thermal shock resistance and good thermal conductivity performance.

3. Beta SiC powder is a very good special coating.

β-SiC has a diamond structure and spherical shape, with ultra-wear resistance, corrosion resistance, superconducting heat, low thermal expansion coefficient and other characteristics. Beta Silicon carbide powder has a good application of the special coating. The β-SiC ultrafine powder coated onto conventional materials, which will be a substantial increase in wear life. Coating β-SiC material to aluminum piston can increase 30-50 times of the life of the piston.

4. With the high hardness of Beta Silicon carbide powder, it is a great abrasive polishing material

β-SiC is abrasive polishing materials whose grinding efficiency is much higher than white fused alumina and α-SiC. Beta SiC to made grinding paste, slurry, high-precision and ultra-wear-resistant coating emery cloth belt also has a good prospect.

5 Beta SiC is widely used as high-grade special additives

By adding β-Sic can greatly improve the thermal conductivity, lower coefficient of expansion, increase wear resistance of polymer composites and metal materials. Adding ultrafine β-SiC powder could greatly improve the performance of high-strength nylon materials, special engineering plastics, polyether ether ketone (PEEK), rubber tires, lubricants and other compression.

6 Beta SiC powder could improve the C powder fluidity.

For β-SiC as an additive add to C powder could greatly improve the fluidity and adhesion. And the add amount is about 5% could greatly help.

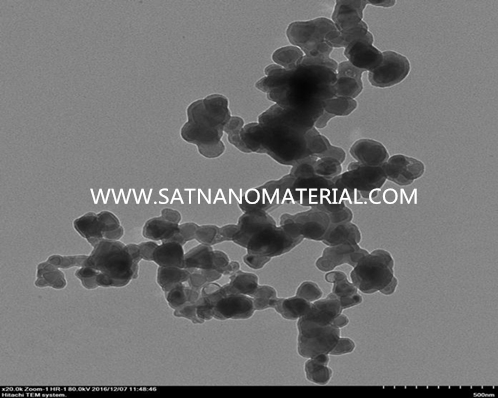

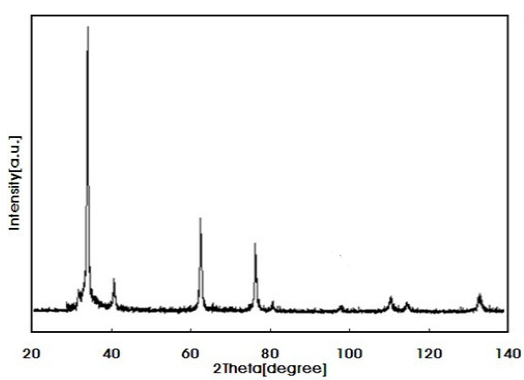

SEM & XRD of silicon carbide powder:

Storage conditions:

silicon carbide powder should be sealed and stored in a dry and cool environment. It should not be exposed to the air for a long time, to prevent agglomeration due to moisture, affecting the dispersion performance and use effect, and should avoid heavy pressure, do not contact with oxidant, and transport according to ordinary goods.