What Is a Nanocrystalline Core for Electric Vehicles?

Dongguan JH Amorphous offers high-performance nanocrystalline cores designed specifically for electric vehicle (EV) applications. These cores are made from Fe–Cu–Nb–Si–B nanocrystalline soft magnetic alloys, featuring ultra-fine grain structures (~10–20 nm) that provide exceptional magnetic properties. They are ideal for use in power electronics such as inverters, onboard chargers (OBC), DC/DC converters, and EMI filters, contributing to improved energy efficiency, reduced system size, and enhanced thermal stability in EV systems.

Material Characteristics

| Saturation flux density induction |

1.20T |

| Permeability @ 10KHz |

>80000 |

| Permeability @ 100KHz |

>20000 |

| Curie temperature |

570 °C |

| Stacking factor |

0.8 |

| Resistivity |

115 μΩ.cm |

| Working Temperature |

-40 ~ 140°C |

| Density |

7.2 g / cm3 |

| Ribbon Thickness |

12 ~ 20 μm |

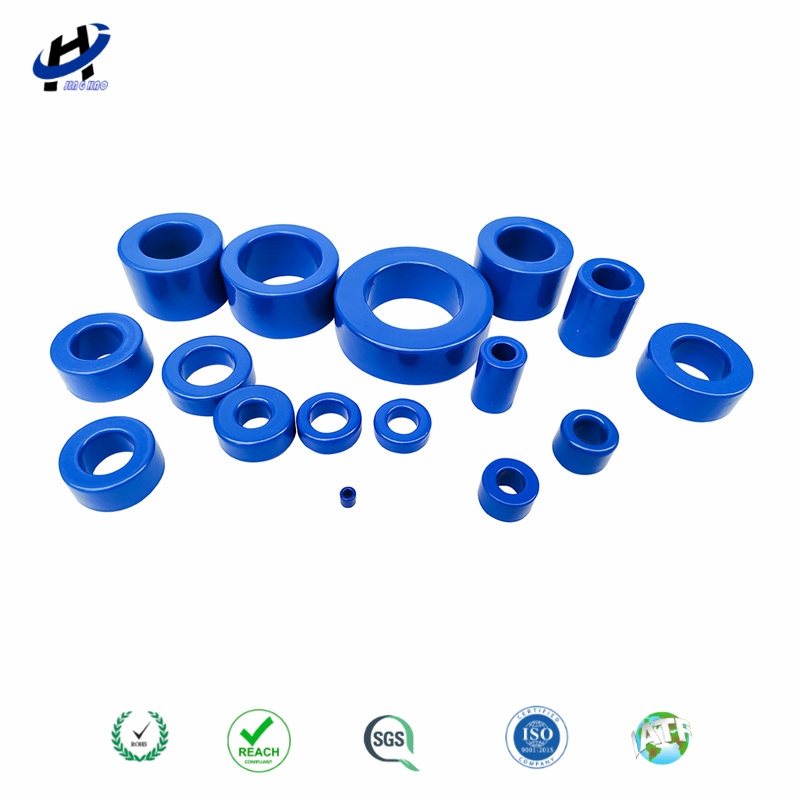

| Core shapes |

Troidal core / C Core / Customizable |

| Finish |

Coating / Casing / Customizing |

Key Features

-

High Magnetic Permeability

Enables efficient energy transfer and minimizes core losses, crucial for high-frequency applications in EV power electronics.

-

Low Core Losses

Reduces energy wastage and heat generation, enhancing overall system efficiency and reliability.

-

Wide Operating Temperature Range

Maintains stable performance from –40°C to +120°C, suitable for the demanding thermal environments in EVs.

-

High Saturation Flux Density

Allows for compact core designs without compromising on performance, contributing to space-saving in EV components.

-

Excellent Thermal Stability

Ensures consistent operation under varying temperature conditions, enhancing the durability and longevity of EV systems.

-

Low Magnetostriction

Minimizes mechanical noise and vibration, improving the acoustic comfort of EVs.

Ideal for Electric Vehicle Applications

-

Inverters & DC/DC Converters

Enhance power conversion efficiency and reduce size and weight of the powertrain.

-

Onboard Chargers (OBC)

Improve charging speed and efficiency, contributing to reduced charging times for EVs.

-

EMI Filters

Provide high attenuation of electromagnetic interference, ensuring compliance with automotive EMI standards.

-

Motor Drives

Enhance motor performance and efficiency, leading to improved vehicle range and responsiveness.

Custom Options

| Parameter |

Specification |

| Outer Dimensions |

4 ~130 mm |

| Core Material |

Fe-based Nanocrystalline / Fe-based Amorphous |

| Inductance & Impedance |

Customizable upon request |

Customized sizes, inductance values, and coating types are available. Contact us for technical consultation and design support.

Why Choose Dongguan JH Amorphous Magnet Cores

-

Precision manufacturing with consistent quality

-

Space-saving design optimized for modern electronic systems

-

Rapid prototyping and flexible production scalability

-

Full compliance with RoHS/REACH environmental regulations

Certificates

Dongguan JH Amorphous, a leading professional one-stop amorphous cores manufacturer.

We offer magnet solutions from design to worry-free after-sales. Let talk about your distinct project now!