Selective Catalytic Reduction (SCR)

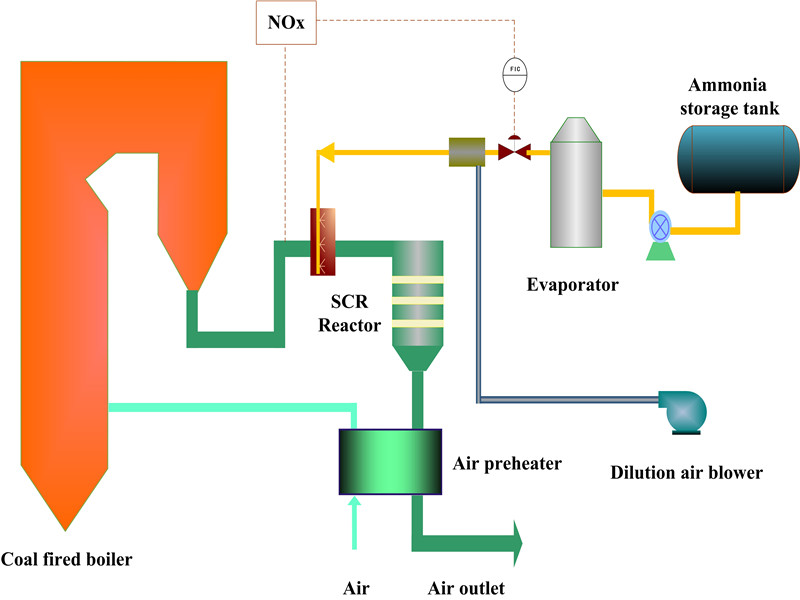

Selective Catalytic Reduction (SCR) is widely applied all over the world as a proven denitration technology, is a process of chemically converting nitrogen oxides (NOx) into nitrogen (N2) and water (H2O) by using catalyst to realize NOx removal in the flue gas. And a gaseous reductant, typically anhydrous ammonia, aqueous ammonia or urea, is added to a stream of flue or exhaust gas and is absorbed onto the catalyst.

ACT owns the most comprehensive DeNOx technologies with the support of state-level R&D center to carry out CFD numerical simulation and physical model test.

When SCR reaction temperature downstream the desulfurization and dedusting system is 250~280℃, the denitration efficiency can be higher than 80%.

Features:

- High NOx removal efficiency (> 90%)

- Excellent reliability

- Mature technology

Selective Non-Catalytic Reduction (SNCR)

Selective Non-Catalytic Reduction (SNCR)

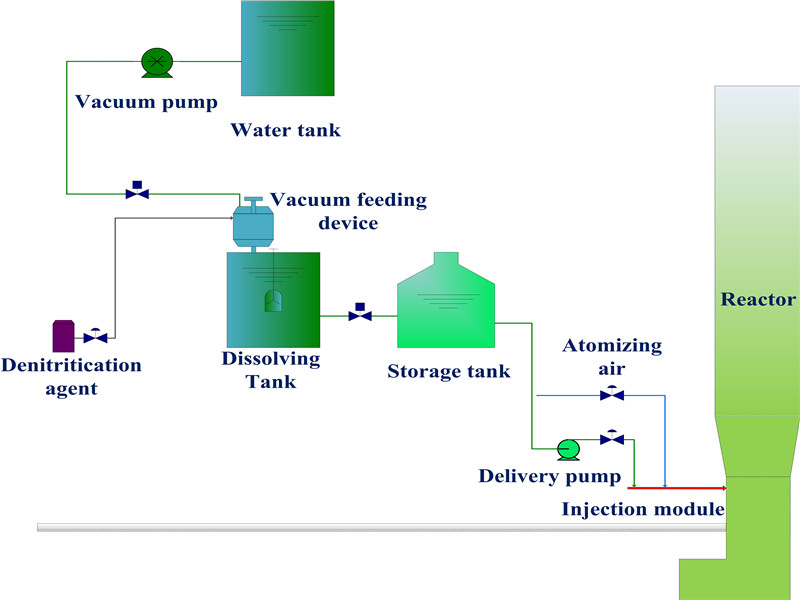

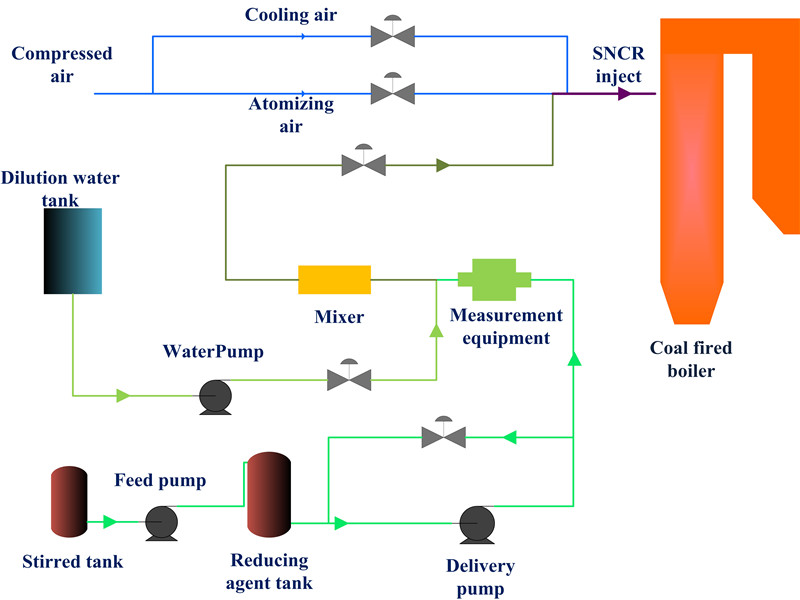

Selective Non-Catalytic Reduction(SNCR) is a process by injecting ammonia-based reagents into the furnace where the temperature is in the range of 850°C to 1100°C, normally in the upper area of furnace or inlet of cyclone separator. The reagents react with NOx into N2 and H2O, NOx reduction could reach 40-70% under proper reaction condition and temperature, and ammonia slip concentrations could be well controlled.

Features:

- NOx removal up to 60-70% for CFB boiler, and 40-50% for PC boiler;

- Partition adjustable design, adapt to various conditions with different temperature

- Modular design, simple system with small footprint and low investment

Circulating Oxidation Absorption Denitration (COA)

Based on hundreds of D-MEC units, ACT has independently developed a co-denitration technology (COA). Normally 95% of NOx is NO contained in the flue gas, and which is insoluble in water, so it’s difficult to remove by using the calcium-based absorbents with water membrane. COA is based on the circulating fluidized bed with intense turbulence, it take the absorbent with large BET surface as the carrier, a special additive is added for oxidation and catalysis, to convert the NO to NO2, then realize the NOx removal by reaction with the absorbent.

Reaction principle:

2NO+O2 → 2NO2

3NO2 + H2O → 2HNO3 + NO

Ca(OH)2 + 2HNO3→ Ca(NO3)2 + 2H2O

Features:

- Denitration temperature ≤ 100°C, efficiency up to 40-60%

- Efficiency up to 70-80% combined with SNCR

- Sub-system to D-MEC unit, great investment reduction

- Adapt to various conditions, boiler load range: 30 to 110%

- Modular design, Simple system with small footprint

- No waste water, no secondary pollution