When striving for cost-effective production of components for automotive industry, from the metal/plastic forming process to the finish-machining operations. For the parts to be ready for assembly, machining operations like Turning, Drilling, Milling, Broaching, Threading are required.

JY Machinery provides CNC machined service to help your business in the following ways:

Production of Complex Parts and Components with Great Accuracy

High Speed Production

Cut down the Production Expenses and Boost Business profits

Product Description:

|

Material

|

1. Stainless Steel: SS303, SS304, SS316, SUS420J2, etc

2. Steel: 12L14, 12L15, C45(AISI1045), etc

3. Carbon Steel: CH1T, ML08AL, 1010, 1035, 1045, etc

4. Alloy Steel: 10B21, 35ACR,40ACR, 40Cr, 35CrMn, etc

5. Aluminum or Aluminum Alloy: Al6061, Al6063, etc

6. Brass: C3604, C38000, etc

|

|

Surface Treatment

|

Zinc plated, Nickel plated, Chrome plated, Passivation, Oxidation, Anodization,

Geomet, Dacromet, Black Oxide, Phosphatizing, Powder Coating and Electrophoresis, etc

|

|

Standard

|

ISO, DIN, ANSI, JIS, BS and Non-standard.

|

|

Certificate

|

GB/T19001-2008/ISO9001:2015

It can match ROHS,SGS and environment protection

|

|

Products Range

|

Dia: 2-200mm or as your request

|

|

Manufacture Process

|

Raw Material/QC/Heading/Thread/HeatTreatment/Surface Treatment/QC Inspection/Sorting and Packing/Shipping

|

|

Tolerance

|

+/-0.005mm or as your request

|

|

Lead Time

|

Sample:3-7 days after order confirmed or as your request

|

|

After-sales Service

|

We will follow up every customer and solve all your problems satisfied after sale

|

Production Capabilities:

|

Manual

|

Turning

|

Milling

|

|

Gringding

|

Prototyping

|

Drilling

|

|

Broaching

|

Automic

|

CNC Milling

|

|

CNC multi axis

|

CNC lathe turning

|

Production milling

|

|

Production turning

|

Prototyping

|

Thread milling work

|

|

CNC Production turning

|

CNC prototyping

|

Production gear manufacturing

|

Technic Series:

|

CNC machining

|

Laser Cutting

|

Turning

|

|

Grinding

|

Milling

|

Hobing

|

|

Casting(Sand/die casting)

|

Stamping

|

Welding

|

|

Bending

|

EDM

|

Wire Cutting

|

|

Laser engraving

|

Knurled

|

Etc...

|

More CNC Machined Parts:

Our Factory:

Why Us?

-

We are a professional manufacturer specializing in manufacturing various metal parts, including CNC precision turning parts, CNC precision milling parts, automatic lathe parts, EDM wire cutting parts etc for over 10 years.

-

With experienced technical engineers and modern inspection equipment, our factory can help you to lower cost at the moment of worldwide financial crisis.

-

We are committed to focusing on the client's demand and satisfaction, and to providing high quality products at competitive prices according to your drawings or samples. Special parts for your special needs!

-

Our strong R&D and QC department can control the products to meet your strict requirment, 100% inspection on critical dimensions with high accuracy +/-0.005mm.

-

Factory direct price and on time delivery.

-

Small quantity acceptable.

-

Free samples available.

-

OEM workable.

Quality Control:

Our principle is that no products are allowed to be produced without confirmation of the samples and drawing,meanwhile our company has the capability of production and quality controlling in the whole process from the selection of raw materials to the production of our products ,even to pre sales and after-sales service.We are able to ensure the stable quality of our products through controlling the key points with a variety of techniques and analysis means.

Testing Equipment:

Micro hardness tester, atomic absorption spectrometer, spectrophotometer, B&R&V three sclerometer, tool microscope, metallographic microscope, 3D imaging instrument, electronic universal testing machine, electronic balance, plug, two dimensional test instruments, pressure tester, tension tester, torque tester etc.

Raw Materials Control:

-

Strict supplier management and control measures

-

Perfect monitoring and control process

-

Data analysis based on the actual situation

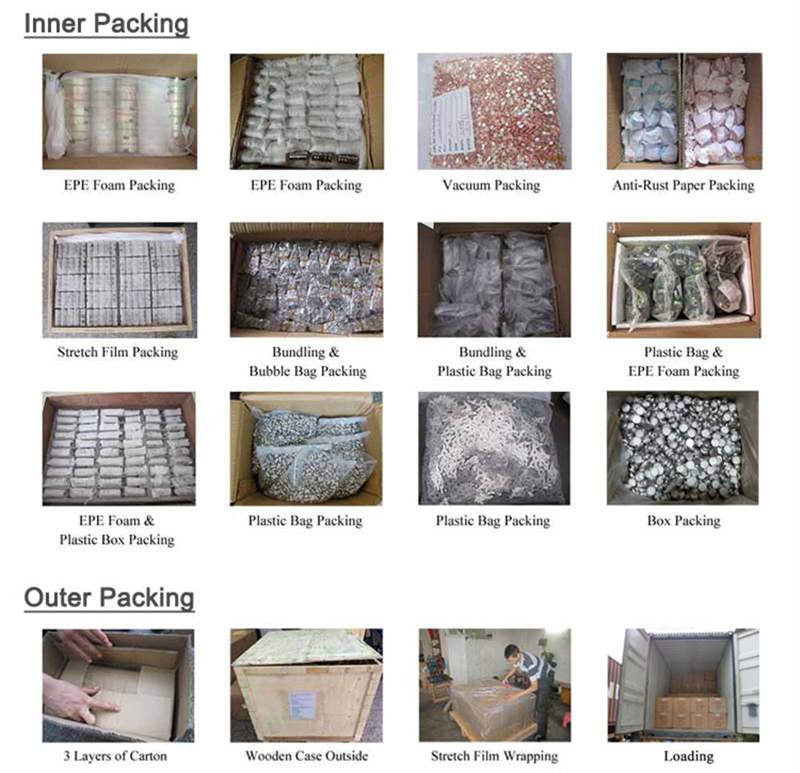

Packing Details: