Packaging Laser Coding Marking Machine

The packaging laser coding machine does not need consumables and does not produce any chemical substances harmful to the environment and human body. it is an environment-friendly marking mode with long laser life, maintenance-free operation and low cost; four-layer board design is adopted to improve the anti-interference ability. and the use of a new generation of integrated circuits and a variety of protection circuits, so that the system has strong anti-interference ability, high reliability, good linearity and high repetition accuracy.

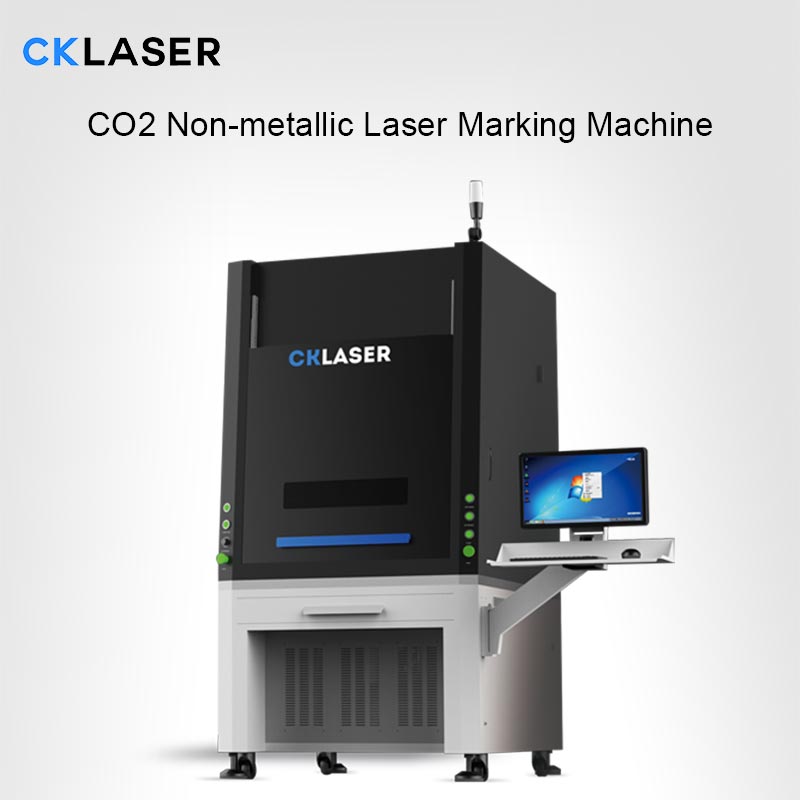

Laser equipment recommendation:

| Carbon dioxide Non-metallic Laser Marking Machine enclosure is completely made from metal sheets with an integrated full-cover design. After upgrade, the space use is more reasonable, with three dimension versions available - Large, Medium and Small. Moreover, it can be compatible with CO2, FB, UV and many other models. |

| Supermini CO2 laser marking machine is used for laser marking and engraving of non-metallic materials, equipped with 2.5-inch oversized optical system to achieve fine, fast and large format laser marking. |

|

|  |

Functional features:

Dot matrix laser marking.

The marking laser machine is mainly to completely depict the trajectory of the characters to be identified, while the dot matrix laser machine is to mark some important track points of the characters.Therefore, in the case of the same energy, the printing speed of the new dot matrix laser printer is faster.

Separate film underlining.

It realizes the easy tearing effect of the flexible packaging, and can maintain the integrity of the film, so that the outer film is intact, so that we can effectively prevent the goods in the package from being exposed to light and moisture.

Locate and underline the packaging material.

Tearing the thread through the human eye is clearly visible, so tearing the package is easy for consumers. Laser marking and laser drilling technology can effectively prevent the expansion of small holes and avoid the damage to the integrity of packaging, and can have good air permeability and moisturizing effect at the same time.

Process application: