Polyurethane foam grouting waterproof coating materials is a reactive solidified film-forming high-molecular waterproofing coating, polymerization reaction.It used for waterproofing in toilets, baths, balconies, parking lots, etc.

It is more suitable for waterproofing in complex shapes and pipes construction.

Type

-One Component Water-Soluble Polyurethane

Key features

-Low viscosity, water quick dispersion happening reaction, forming impervious elastic colloidal concretion body, has the good plugging stop-water performance.

-With water formed ivory elastic colloidal concretion body, has high compressive strength, low temperature resistance, good elasticity, penetration-proof quality is good wait for a characteristic.

-Can permeate into crack depth, reaction after forming institutional concretion body omni-directional fill plugging cracks.

-Good expansion, good performance of reaction with large volume water.

Typical properties

PU-110A Gel Type

|

Appearance

|

Yellowish transparent liquid

|

Density (g/cm3)

|

1.0-1.2

|

Viscosity (mpa.s)

|

200-300

|

Gel time (s)

|

10-50

|

Expansion Ratio (%)

|

20-30

|

Water Embracing (s)

|

45-80 (5-15 times water)

|

|

PU-110B Flex Type

|

Appearance

|

Yellowish transparent liquid

|

Density (g/cm3)

|

1.0-1.2

|

Viscosity (mpa.s)

|

200-300

|

Gel time (s)

|

10-60

|

Expansion Ratio (%)

|

50-200

|

Water Embracing (s)

|

50-100 (5-15 times water)

|

The product video

|

|

|

|

Cement grouting material foaming effect display

Youtube video link:

|

Cement grouting material plugging effect show

Youtube video link:

|

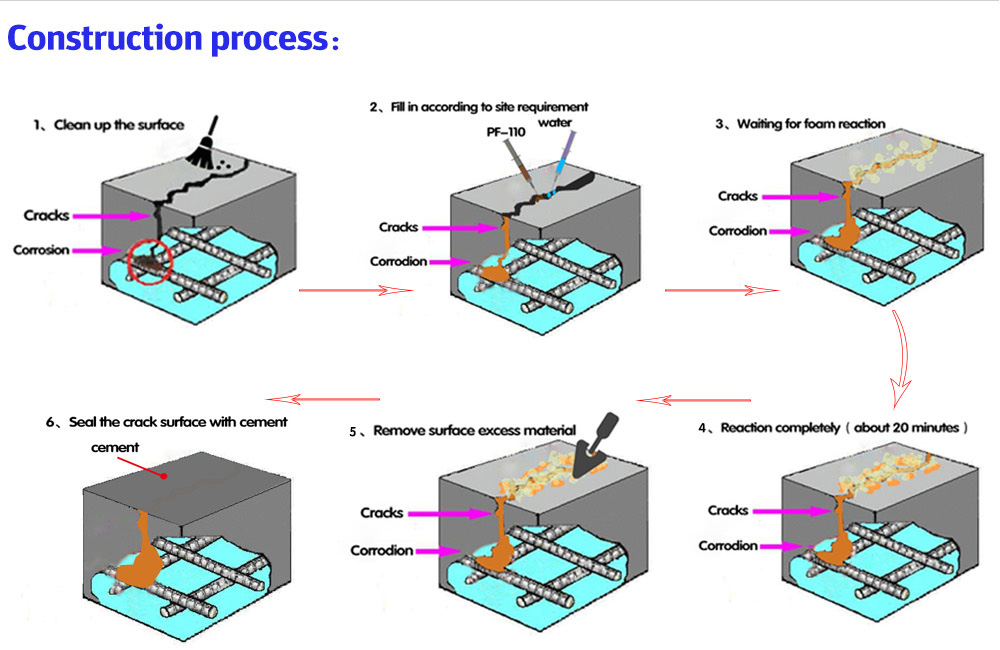

Application

-Pool, towers, basement, shelter building such as irrigation seam plugging and waterproof coating.

-Metal and concrete pipe shaft preservation and steel structure of the corrosion.

-Underground tunnel, buildings foundation reinforcement.

-Architectural engineering distortion seam, construction seam, structural cracks plugging and reinforcement.

-Port and dock pier, DAMS, hydropower station with the curtain grouting reinforcement plugging.

-Geological drilling slurry-supported plugging, oil exploitation of water and mine where water gushing closed etc.

Other similar products

|

Model Nuber

|

Product name

|

|

PU-110

|

One Component Hydrophilic Water-Soluble Polyurethane Water-stop Foam Gel

|

|

PU-111

|

One Component Oil-Soluble Polyurethane Hydrophobic Foam

|

↑ ↑ ↑ ↑ ↑ Please click product model nuber for more informations

Storage and handling

-Available in 25 kg/ barrel or 10 kg/ barrel for Polyurethane foam grouting waterproof coating materials

-Store products in tightly closed original containers at 5-40℃

-Shelf life: 9 months from delivery date

-According to non-dangerous goods transport