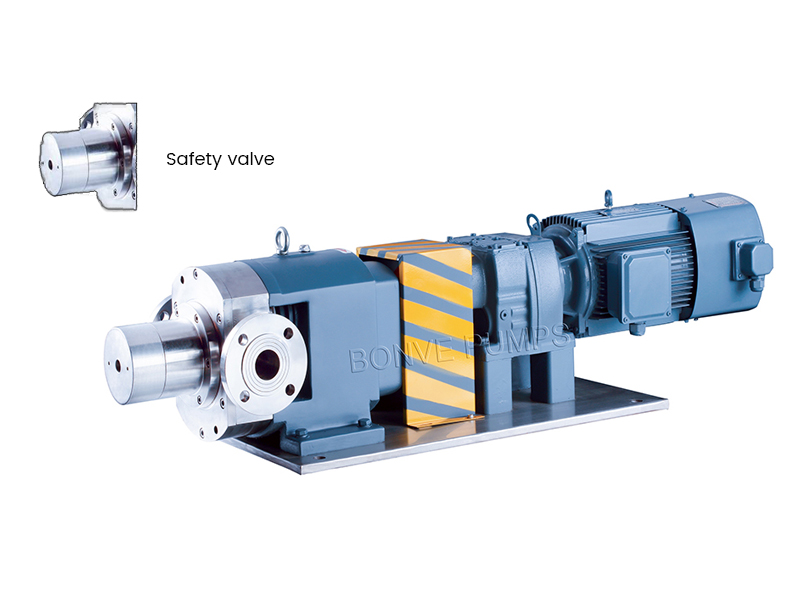

Positive displacement lobe pumps with safety valve design

PUMP INTRODUCTION

The positive displacement lobe pumps must

be protected from excess pressure when they are operating. BONVE lobe pumps can be fitted with a stainless steel safety valve or a safety by-pass. The

valve protects the pump and prevents excessively high pressure arising in the

circuit. It reduces the differential pressure between suction and discharge,

but not the maximum pressure within the plant. Safety valve is an important

method to protect the pump, to prevent over-pressure damage to the pump.

PUMP FEATURES

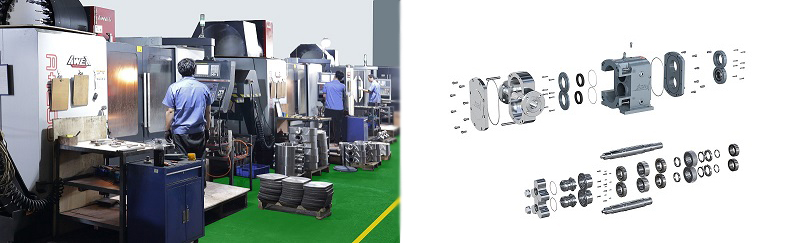

We pursue

excellence, more than ten years of dedicated research and development, only to

allow customers to obtain long service life, high precision, strong

versatility, customized lobe pump.Below are the positive

displacement lobe pumps main features.

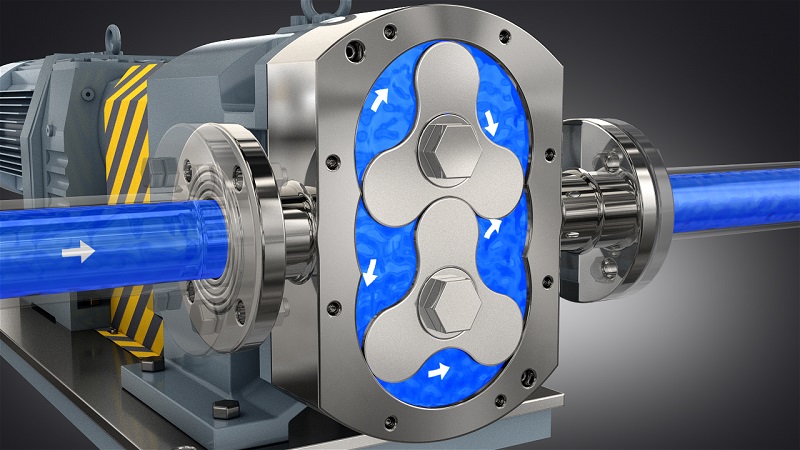

Long service life: gap is kept between the

rotor and the rotor, the rotor and the pump body; no friction; simple assembly

and disassembly, easy maintenance and cleaning, and few wearing parts; energy

saving, low failure rate, reliable sealing and low noise.

High precision: all main parts including the pump chamber, rotors, gear box, shafts,

bearings are processed by CNC.

Strong versatility: we offer the targeted seal type and rotor type as per the specific

product to be transferred. The rotors and seal types are interchangeable.

Customization: according to the customers installation condition, pump port direction

can be horizontal and vertical. And the connection types can be screw and clamp

type, etc.

TECHNICAL PARAMETERS

|

Model

|

Displace

-ment

|

RPM

|

Flow

|

Dis. Pre.

|

Power

|

Vacuum

|

Port size

|

Max

viscosity

|

|

(L/r)

|

(r/min)

|

(m³/h)

|

(Mpa)

|

(kW)

|

(Mpa)

|

(mm)

|

(cp)

|

|

25BV12-05

|

0.06

|

10-1000

|

0-0.5

|

0-1.2

|

0.37-1.1

|

-0.080

|

25

|

1,500,000

|

40BV12-2

|

0.15

|

10-1000

|

0-2

|

0-1.2

|

0.75-2.2

|

-0.080

|

40

|

1,500,000

|

50BV12-5

|

0.32

|

10-800

|

0-5

|

0-1.2

|

1.5-4

|

-0.085

|

50

|

1,500,000

|

65BV12-10

|

0.65

|

10-600

|

0-10

|

0-1.2

|

2.2-7.5

|

-0.085

|

65

|

1,500,000

|

80BV12-20

|

1.74

|

10-500

|

0-20

|

0-1.2

|

4-15

|

-0.095

|

80

|

1,500,000

|

90BV12-30

|

2.60

|

10-500

|

0-30

|

0-1.2

|

5.5-22

|

-0.095

|

100

|

1,500,000

|

100BV12-40

|

3.65

|

10-500

|

0-40

|

0-1.2

|

7.5-30

|

-0.095

|

100

|

1,500,000

|

125BV12-50

|

4.60

|

10-500

|

0-50

|

0-1.2

|

7.5-37

|

-0.095

|

125

|

1,500,000

|

140BV12-70

|

6.10

|

10-500

|

0-70

|

0-1.2

|

11-45

|

-0.095

|

150

|

1,500,000

|

150BV12-80

|

7.63

|

10-500

|

0-80

|

0-1.2

|

11-55

|

-0.095

|

150

|

1,500,000

|

200BV12-120

|

11.56

|

10-400

|

0-120

|

0-1.2

|

15-75

|

-0.095

|

200

|

1,500,000

|

250BV12-150

|

14.22

|

10-400

|

0-150

|

0-1.2

|

18.5-90

|

-0.095

|

250

|

1,500,000

|

300BV12-200

|

20.80

|

10-300

|

0-200

|

0-1.2

|

22-110

|

-0.095

|

300

|

1,500,000

|

350BV12-300

|

32.60

|

10-250

|

0-300

|

0-1.2

|

45-160

|

-0.095

|

350

|

1,500,000

|

400BV12-400

|

50.40

|

10-250

|

0-400

|

0-1.2

|

55-200

|

-0.095

|

400

|

1,500,000

|

Note:

1. Tested medium: water. Your liquid's density, viscosity and temperature are necessary to supply when choose the pump.

2. Speed, flow rate, electrical power and pressure will be varified according to different liquid properties.

3. Port size can be changed as needed.

APPLICATIONS

-

Beverages: Beer,carbonated soft drinks, coffee liquor, fruit juice

concentrates, milk drinks, sugar

solutions, wine, yeast slurries;

-

Confectioneries:

Biscuit cream, caramel, chocolate, cocoa butter, cocoa mass, condensed milk,

fat, fondant, glucose, high-boiled sugar syrup, jellies;

-

Dairies: Butter, cheese, cream, egg,

ice cream, milk, quarg, whey, yoghurt;

-

Pharmaceutica:

Blood, cell cultures, enzymes, ointments, protein solutions, syrups;

-

Prepared Foods: Additives, baby food, edible oils, fruit puree,

meat chunks, jam, petfood, sauces, soups,

toppings;

-

Consumer

products: Soap&Detergents, AES, LAS, AOS, K12, glycerin, fatty alcohol, bath shampoo, skin cream, shampoo, detergent, tppthpaste, liquid

soap, washing power slurry, etc.

-

Sugar: Glucose, high/low green syrup, liquid sugar, magma, massecuite, molasses, sugar syrup, thick

juice, treacle.

CERTIFICATES

FACTORY FIELDS

OUR PARTNERS

CONTACT US

We welcome you

to contact us for a pump solution if have any demand.

Contact person:

Ms. Kepner

Tel:

+86-574-87769810 Fax: +86-574-62962898

Mobile/Whatsapp/Wechat:

+86 15869300458

Email: bvsales1@bonvepumps.com