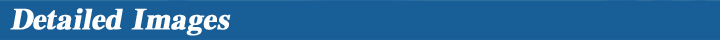

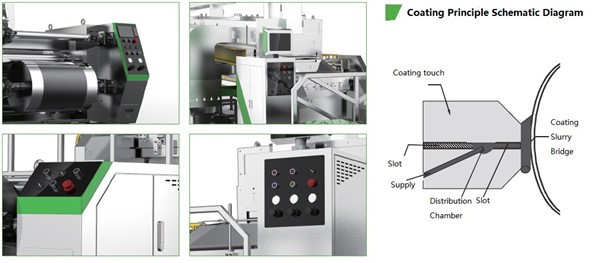

Precision Extrusion Coating Machine for Battery Production Line

Advantage

1. The feeding system and the control system are closely matched to achieve stable high-precision coating, and the weight error is plus or minus 1%.

2. Stable structure, suitable for large-scale production

3. Easy to operate, touch screen interface design

4. 4 Online surface density detection system (optional), online CCD visual inspection system (optional) bad section identification system (optional)

|

No.

|

Project

|

Technical Parameters

|

|

1

|

Process adaptability

|

Lithium battery pole piece coating

|

|

2

|

Coating method

|

Continuous coating / gap coating

|

|

3

|

Rewinding volume configuration

|

Single-axis/two-axis manual roll change, automatic roll change

|

|

4

|

Heating method

|

Electric heating / steam heating / oil heating

|

|

5

|

Oven configuration

|

Active over roller + suspension oven, length optional

|

|

6

|

Mechanical speed

|

Coating speed +10%

|

|

7

|

Coating speed

|

15~10m/min (depending on the model)

|

|

8

|

Coating width

|

500mm / 650mm

|

|

9

|

Coating thickness

|

50~150um

|

|

10

|

Thickness accuracy

|

±0.5μm (when the coating thickness is greater than 1um)

|