Intelligent 3Ply Corrugated Cardboard Production Line

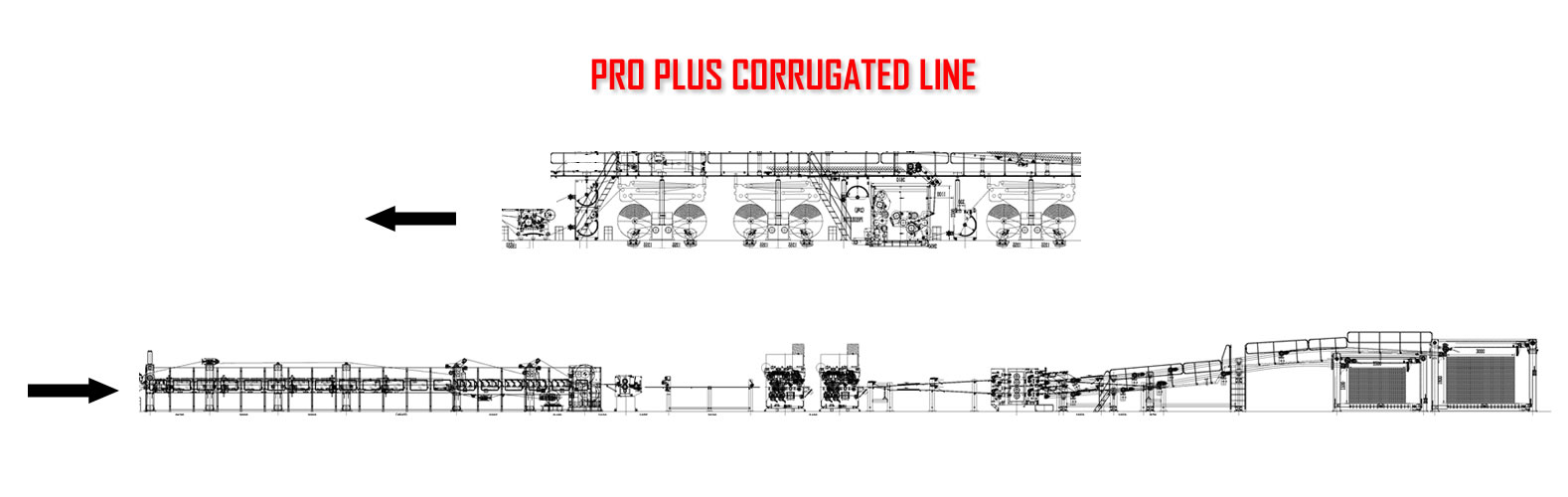

PRO PLUS 3ply corrugated cardboard production line

Cardboard thickness: 3Ply (2ply, 3ply can be made)

Width: 1800-2800mm

Speed: 250-350meters /min

DCS Full Servo Control

Intelligent Control System

Features:

• Fully servo control system, intelligent corrugated cardboard line. Fast change or cassette type single facer for option

• Speed 250-350m/min, width 1800-2800mm.

• Pro Plus design Capacity: Able to handle 1200 order changes with production over 700000m2 in 24 hours

• Order change speed: Single Layer production: 300m/min, Double Layer production: 260m/min

• Digital managerment of the production line, instelligent control system according to the paper, speed, environment, materails, temperature and auto statistics difference. Non stop production with liquid cooling servo motors cutting

• Automatically control the tension, paper temperature, glue making and application, intelligent order arrangement in production of combinations

• DCS center control system with complete integration of electrical, electronic and mechanical manufacturing that truly complies with Germany Industrial 4.0

• Using EtherCat communication technique for logic, simple and high machinery functionality concept for complete line

• Can be customized according to different customer's situation

Product Show

FAQs

1Q: Are you the manufacturer?

A: Yes, we are the professional manufacturer combined with WEST RIVER, KL&Japan Shinko, Nantai & Japan Asahi, Jiayi, Guanwei, Jinshun brand machines.

2Q: Where are your factory located in ?

A: Our factories located in Shanghai, Guangzhou, Foshan, Zhaoqing Cities in China

3Q: How to choose the corrugated machine ?

A: According to your market requirement for the cardboard thickness, your target requirement, raw material size, we will give you the best choice of the corrugated machine.

4Q: What can you do for me?

A: Usually the customer need to choose the corrugated machine, flexo printer, die cutter and other converter machine separately by different supplier, but we will give you the whole plan design solution from A to Z, what you need to do is just tell us your target, then you will get the most suitable proposal from us.

5Q: How to control machine quality ?

A: All material are environmental protection,non-pollution, We have professional technicists to supervising to production, Our professional department to examine about every production process

6Q:What can you do if the machine broken?

A: We provide the machine remote service system, and the warranty period is 1 year. If the broken parts can't repair, we can send the new parts to replace the broken parts for free, but you need to pay the freight. After warranty period, we will charge for the maintanance, and we supply the technical support for the whole life of the equipment.