Professional Tube and Pipe Laser Cutting Machine for 20-300mm

|

Model

|

Laser

|

Tube length

|

Cutting range

|

Application

|

|

F6015GE

|

1KW-2KW

|

6 Meters

|

20-150mm

|

SS CS brass, aluminium pipe and tube

|

|

F6020GE

|

1KW-2KW

|

6 Meters

|

20-200mm

|

SS CS brass, aluminium pipe and tube ,U

beam. L beam..

|

|

F6030GE

|

1KW-2KW

|

6 Meters

|

20-300mm

|

SS CS brass, aluminium pipe and tube ,U

beam. L beam..

|

|

Cyptube/Protube

control.WSX or Precitec cutting head.auto materials feeding and finished

parts collection….

|

F6030GE Professional pipe cutter has bigger chuck than the other two. It is more suitable for some big tube cutting application.

Laser cutting tube is a highly productive and

flexible method of tube processing which is now finding applications in all

industries.

Laser tube cutting machines are designed both to cut hole

profiles and end profiles (mitres or cod mouths) on round, square, oval,

triangular and other special section tubes.

Accurate laser cutting of

highly complex shapes within the tube is possible...

The F6030 Laser Tube offers the

following:

·

Max raw material length – 6m

·

Max outside dia. – 300mm

·

5,00kg capacity automatic bundle loader

· 90/45 degree tilting laser head

Tube laser

cutting eliminates all traditional marking out, sawing, drilling, deburring and

shaping operations carried out with conventional tube processing.

Traditional fixed costs of punches, clamps, tools and jigs are also eliminated.

The tube laser

machines are CNC controlled and programmed offline by 3D CADCAM software.

With full automatic loading of tube raw material lengths up to 6 metres,

automatic processing and automatic offload, the process offers very high

productivity. China-made tube laser is more cost-effective .At present ,large amount such tube lasers are used in fabricators' job shops.

Tube Cutting Control System

The laser equipped with professional PA8000 CNC system with a large screen display .

Other software

Lantek’s nesting CAD/CAM software optimizes the material yield and the quality of the results to the maximum.

Lantek Expert provides the most advanced nesting algorithms and mechanization strategies (Thinkingmetal Technology) for any of the existing cutting (laser, plasma, oxy-fuel, water jet technologies) and punching machines.

Lantek Expert achieves an outstanding performance with our Machine Tool Builder Partners, based on our close collaboration with them, but also optimizes the results of machines from manufacturers like Amada, Esab, Ficep, Flow, HK Laser & Systems, Koike, Mazak, Messer, Prima Power, Salvagnini, Trumpf, and many other.

Lantek ensures excellent results, both in nesting and machining, for any cutting or punching machine today and in the future.

In order to facilitate the work of the

operator, a space is reserved below the display for storing consumables and

professional tools. The console has two USB connectors that can be used to

connect U disk and other removable memory to download drawings and programs. In

addition, the machine also has a LAN connector for integrating the machine into

a common network infrastructure.

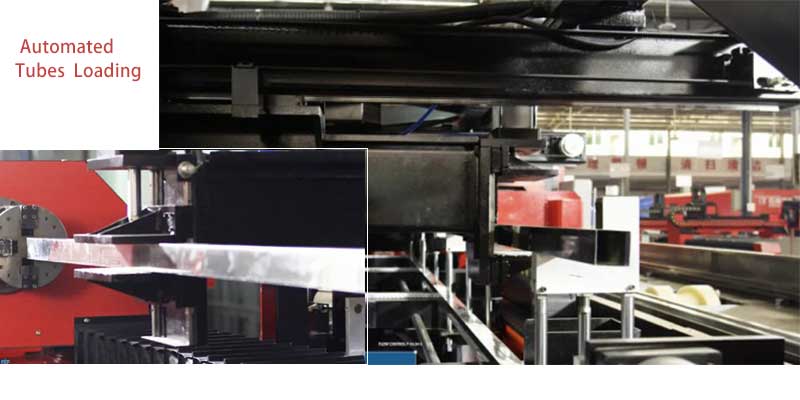

Automated Tubes Loading system

bundle of tubes and pipes can be loaded and feed to the chucks automatically.

Fiber laser has a series of advantages,tube laser cutting machine has gradually been used more and more in tube processing companies.

such as high beam quality, high brightness, high conversion rates, maintenance-free, stable and reliable operation of low cost and small size, etc. Air-assisted cutting is the most advanced level of laser cutting, which is particularly suitable for stainless steel, carbon steel, alloy, brass, copper, titanium and other metal materials precision cutting. It is widely used in metal products, bicycle, metal furniture, fitness equipment, sports equipment, farm machinery, display shelf, fire control.