Our Strength

With fast-delivery and feasible production, Huafu Chemicals helps more and more cooperative melamine tableware factories become outstanding in their local and abroad market. Our factory has two production lines with a yearly production capacity of 12,000 tons. There are 126 factory workers, including 6 Research and Design personnel, and 2 QC personnel. Besides that, the stable machine, reasonable working structure (5 days working and 2 days off for rest for workers in the factory) are all valuable for the guarantee of production capacity.

The normal delivery time is that the delivery can be made within 7-10 days after the order is confirmed. In the special peak season, the delivery will be within 15 days. If it is a particularly urgent cargo, for example, there is not much stock in the clients' factory. After the reason is stated, it can be processed in priority and delivered according to the specified time to meet the special needs of clients.

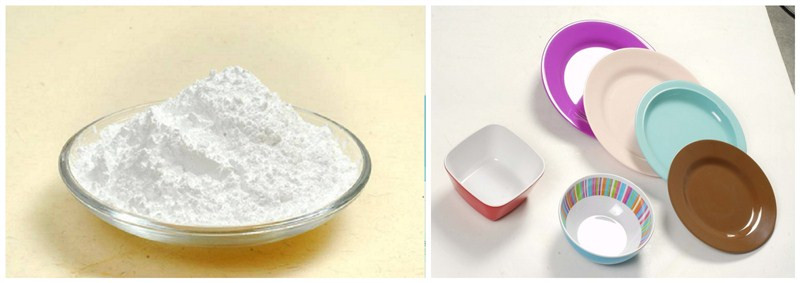

Melamine Formaldehyde Glazing Powder (lg) is also known as glazing powder. The molecular structure of glazing powder is basically the same as melamine resin molding powder. It's a kind of polymer compound. The formaldehyde and melamine reaction resin after drying ball mill into powder raw materials, It is also known as "fine powder" because of no pulp adding. Melamine resin molding powder is avirulent, tasteless, odorless. It is the ideal glazing material for amino mold products with the ability to make products bright, wear-resistant and other characteristics.

Melamine Glazing powder has three varieties:

1. LG110: shinning powder for urea tableware products (A1 and A3 materials)

2. LG220: shinning powder for melamine tableware products (A5 material)

3. LG250: glossy powder for foil papers

SGS Report:

The testing result of submitted sample (MELAMINE

DISC)

|

Test Requested

|

Conclusion

|

|

Commission Regulation (EU) No 10/2011 of 14

January 2011 with amendments

-Overall migration

|

PASS

|

|

Commission Regulation (EU) No 10/2011 of 14

January 2011 with

amendments-Specific

migration of melamine

|

PASS

|

|

Commission Regulation

(EU) No 10/2011 of 14 January 2011 and Commission

Regulation (EU) No

284/2011 of 22 March 2011-Specific migration of

formaldehyde

|

PASS

|

|

Commission Regulation (EU) No 10/2011 of 14

January 2011 with amendments

-Specific

migration of heavy metal

|

PASS

|

Physical property:

Melamine Glazing Powder: non-toxic, tasteless, odorless, is used to make the product tableware bright and shinning.

Typical Properties

|

PRODUCT

|

APPLICATION

|

APPERANCE

|

DENSITY

( g / cm2 )

|

MOISTURE

( %free water )

|

DISC FLOW

( MM )

|

CURING

TIME

( at 170 ˚c )

|

|

LG240/LG220

|

- coating

|

White

powder

|

0.38 - 0.44

|

3.0 Max

|

130 - 140 *

|

20 - 30

|

|

LG2501

|

- coating

- Bushing on

decorative foil paper

|

White

powder

|

0.20 - 0.25

|

3.0 Max

|

125 - 140 *

|

15 - 25

|

Molding Condition

|

TYPE

|

ITEM

|

UNIT

|

CONDITION

|

|

COMPRESSION

|

Mold Temperature

|

˚c

|

165 ± 5

|

|

Mold Pressure

|

kg / cm2

|

150 - 200

|

Applications:

1. Used in the manufacture of melamine tableware and covered on the surface of melamine tableware to play a glazing effect.

2. Used for the production of melamine powder. In the grinding stage of melamine production, glazing powder is a common additive, which can improve the fluidity and processing properties of melamine powder.

Factory Tour: