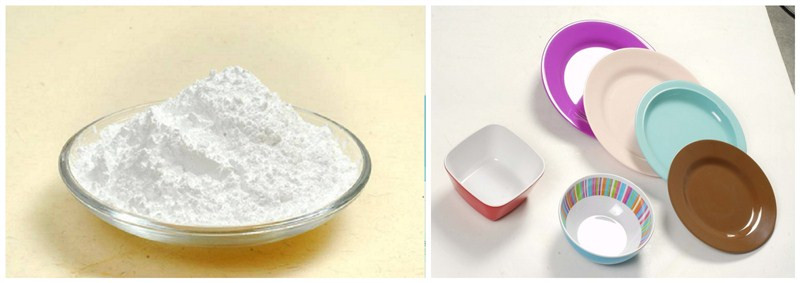

Pure White Melamine Glazing Powder (lg) is also known as glazing powder. The molecular structure of glazing powder is basically the same as melamine resin molding powder. It's a kind of polymer compound. The formaldehyde and melamine reaction resin after drying ball mill into powder raw materials, It is also known as "fine powder" because of no pulp adding. Melamine resin molding powder is avirulent, tasteless, odorless. It is the ideal glazing material for amino mold products with the ability to make products bright, wear-resistant and other characteristics.

Melamine Glazing Powder has three varieties:

1. LG110: shinning powder for urea tableware products (A1 and A3 materials)

2. LG220/LG240: shinning powder for melamine tableware products (A5 material)

3. LG250: glossy powder for foil paper

SGS Report:

The testing result of submitted sample (MELAMINE

DISC)

|

Test Requested

|

Conclusion

|

|

Commission Regulation (EU) No 10/2011 of 14

January 2011 with amendments

-Overall migration

|

PASS

|

|

Commission Regulation (EU) No 10/2011 of 14

January 2011 with

amendments-Specific

migration of melamine

|

PASS

|

|

Commission Regulation

(EU) No 10/2011 of 14 January 2011 and Commission

Regulation (EU) No

284/2011 of 22 March 2011-Specific migration of

formaldehyde

|

PASS

|

|

Commission Regulation (EU) No 10/2011 of 14

January 2011 with amendments

-Specific

migration of heavy metal

|

PASS

|

Physical property:

Glazing Powder: non-toxic, tasteless, odorless, is ideal amino molding plastic material after-Clear, with light to make the product wear, etc. The article coated with melamine resin powder, glazing powder has a shinny and harder surface and resists better to cigarette burns, foodstuffs, abrasion and detergents.

Typical Properties

|

PRODUCT

|

APPLICATION

|

APPERANCE

|

DENSITY

( g / cm2 )

|

MOISTURE

( %free water )

|

DISC FLOW

( MM )

|

CURING

TIME

( at 170 ˚c )

|

|

LG240/LG220

|

- coating

|

White

powder

|

0.38 - 0.44

|

3.0 Max

|

130 - 140 *

|

20 - 30

|

|

LG2501

|

- coating

- Bushing on

decorative foil paper

|

White

powder

|

0.20 - 0.25

|

3.0 Max

|

125 - 140 *

|

15 - 25

|

Molding Condition

|

TYPE

|

ITEM

|

UNIT

|

CONDITION

|

|

COMPRESSION

|

Mold Temperature

|

˚c

|

165 ± 5

|

|

Mold Pressure

|

kg / cm2

|

150 - 200

|

Advantages:

Glazing powder is non-toxic, tasteless, odorless, and it's an ideal amino moulding plastic material.

Glazing powder is used to put on the tableware or on the decal paper to make tableware shinning. When used on tableware surface and decal paper surface, it can increase the degree of surface brightening, makes the dishes more beautiful, generous.

Applications:

It is generally used as glossy material for products and additives for adjusting the fluidity of melamine powder.

Storage:

1. Store in a cool,dry and ventilated storehouse away from moisture

2. Avoid handling or transporting together with acidic or alkaline substances

3. Prevent the material from rain and insolation

4. Load and unload carefully and protect from package damage

5. In the event of a fire,use water,soil or carbon dioxide fire extinguishing media

Factory Tour: