Product Description

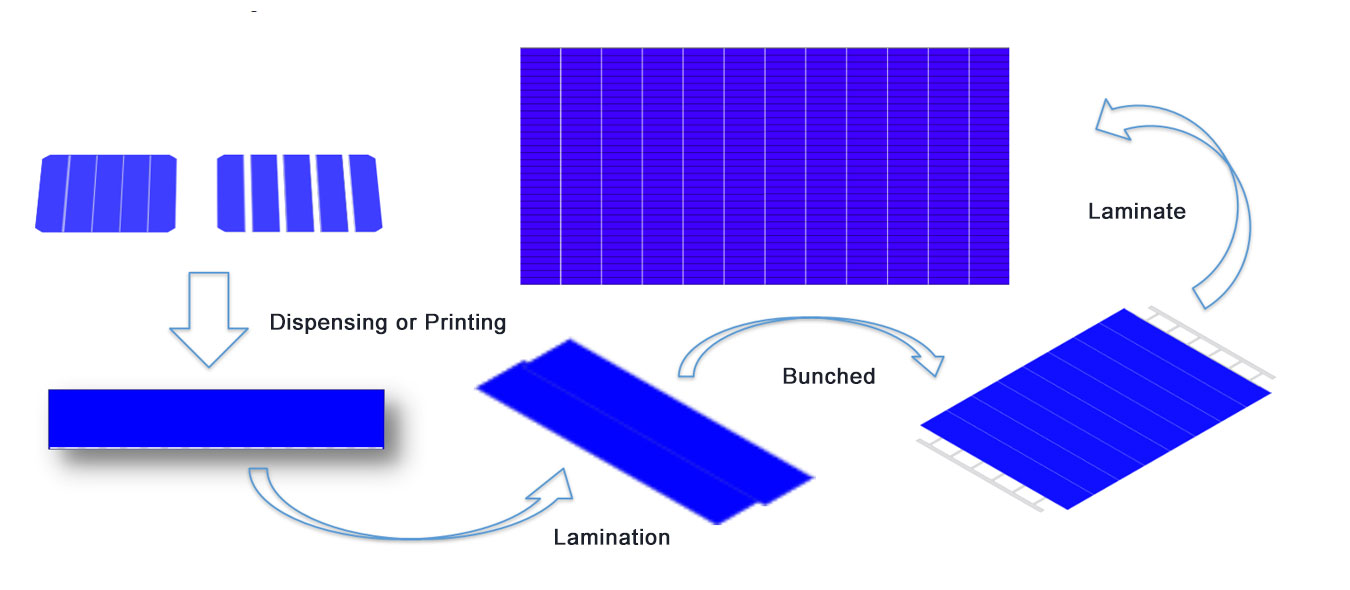

1.Shingled module technology-process

Compared with the normal module process, the shingled process has different interconnect materials, and the process is simpler and more reliable, avoiding defects such as offset welding of the ribbon.

|

Module Type

|

BSM480PM5-72SB

|

BSM485PM5-72SB

|

BSM490PM5-72SB

|

BSM495PM5-72SB

|

BSM500PM5-72SB

|

|

|

STC

|

NMOT

|

STC

|

NMOT

|

STC

|

NMOT

|

STC

|

NMOT

|

STC

|

NMOT

|

|

Maximum Power(Pmax/W)

|

480

|

361

|

485

|

365

|

490

|

369

|

495

|

373

|

500

|

377

|

|

Operating Voltage(Vmpp/V)

|

38.7

|

37.0

|

38.7

|

37.0

|

38.8

|

37.1

|

38.9

|

37.2

|

39.0

|

37.3

|

|

Operating Current(Impp/A)

|

12.40

|

9.77

|

12.53

|

9.87

|

12.63

|

9.95

|

12.72

|

10.02

|

12.82

|

10.11

|

|

Open-Circuit Voltage(Voc/V)

|

46.5

|

44.4

|

46.5

|

44.4

|

46.6

|

44.5

|

46.7

|

44.6

|

46.8

|

44.7

|

|

Short-Circuit Current(Isc/A)

|

13.16

|

10.62

|

13.22

|

10.67

|

13.28

|

10.72

|

13.34

|

10.77

|

13.40

|

10.82

|

|

Module Efficiency(%)

|

21.4

|

21.6

|

21.8

|

22.0

|

22.2

|

STC: Irradiance 1000W/㎡,Cell Temperature 25°C,Air Mass AM1.5 NMOT: Irradiance at 800W/㎡,Ambient Temperatue 20°C,Air Mass AM1.5,Wind Speed 1 m/s

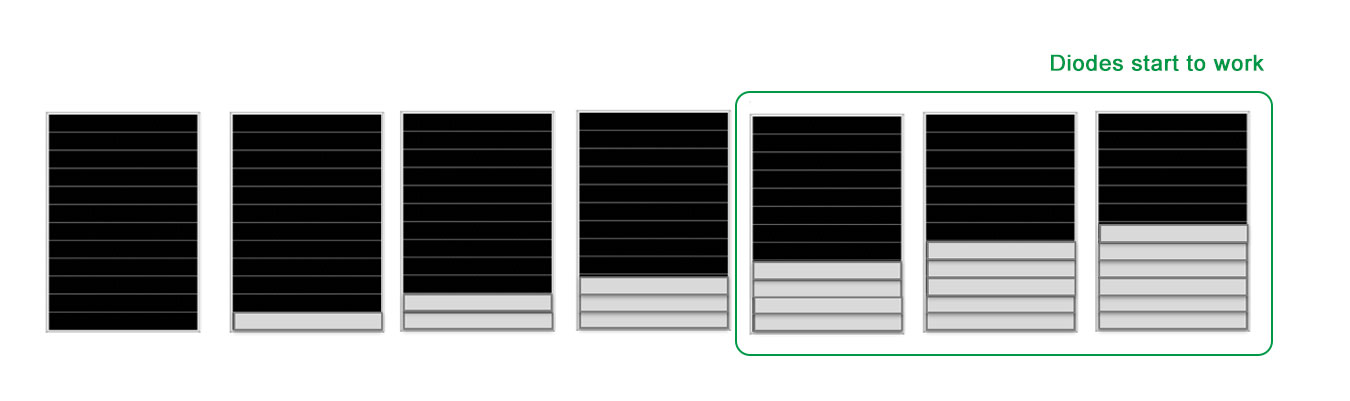

2. When shaded by shadow, shingled modules have the best output power if the shingles modules are installed vertically.

|

The number of cells shaded

by shadow

|

Without occlusion

|

1 row of cells

is shaded

|

Two rows of cells

are shaded

|

Three rows of cells

are shaded

|

Four rows of cells

are shaded

|

Five rows of cells

are shaded

|

Six rows of cells

are shaded

|

|

I(A)

|

10.665

|

9.082

|

7.313

|

5.504

|

10.614

|

10.612

|

10.609

|

|

Pm(W)

|

400.5

|

348.0

|

258.1

|

216.2

|

192.4

|

191.5

|

191.4

|

3. shingled module-Better ability to melt snow

Vertical installation, shingled module cells series and parallel structure, as soon as the snow on one string of cells melts, the module is ready to work, the temperature rise during work further accelerates snow melting. It can effectively increase module power generation time.

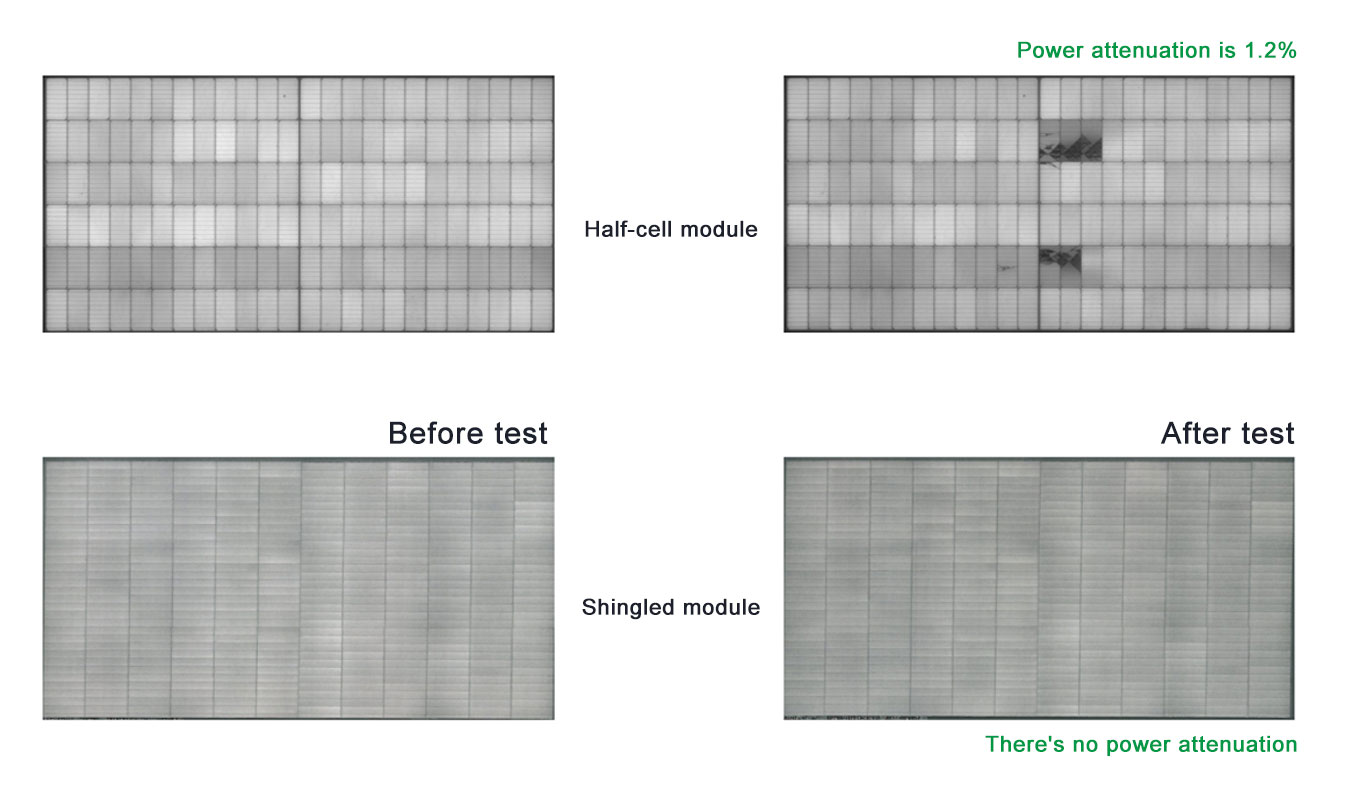

4. shingled module- load-resisting capacity

Under the load of IEC 5400Pa, shingled has no new micro-cracks, although both shingled module and half-cell module passed the test(attenuation < 5%)

High load resisting capacity reduces the production of micro-crack during transportation and power station installation