Why Choose Infrared Medium Wave Lamp Elements?

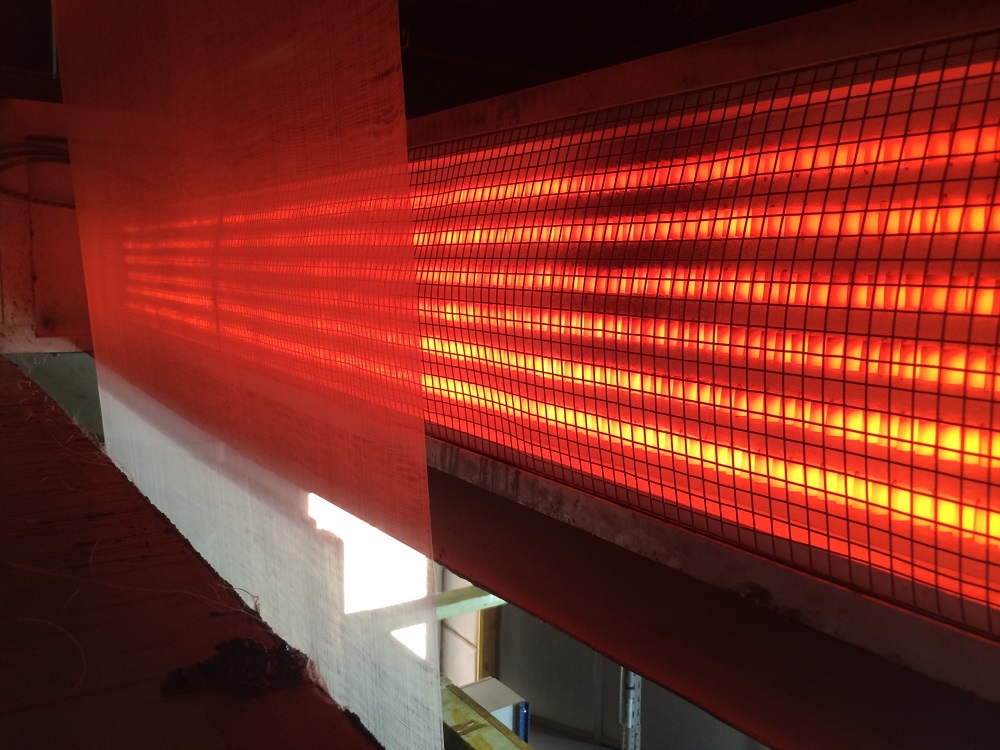

The Infrared Medium Wave Lamp Elements are particularly suitable for the fast heating of surface parts or thin thickness materials. Plastic, water and other solvents absorb particularly well the radiation at this wavelength.

The main characteristics of IR Medium Wave emitters are:

-

Twin tube standard section:23 x11 mm - 33 x15 mm

-

Radiation peak in the range of 2,4 - 2.7µm

-

25 W/cm maximum density of nominal power(to be verified in prototype phase)

-

Filament Response time to Switch on /off between 30 and 70 seconds

-

Long lifetime of the emitter

Basic Description

Quartz Glass Twin Tube Infrared Heating Lamps for Heidelberg Screen Printing Machine Inks Drying IR Paint Curing Element

Medium wave Quartz Infrared Heaters consist of a quartz tube with a nickel or Iron chromium alloy coiled filament. QUICKLY’s MW IR lamps are typically come in diameters of 10 mm,11mm,12 mm,13mm,13.5mm,15 mm,18mm,20mm for Single Tube or with 11 x 23 mm & 15 x 33 mm for Twin Tube. The Lengths of the Medium Wave Quartz Infrared Heaters can vary from 100 mm to 6000 mm as per customers design and specifications. They are available in clear or opaque quartz tube with gold or ceramic reflective coatings that focus the emitted energy onto the substrate. Standard medium wave emitters are not filled with any gases and are not sealed.

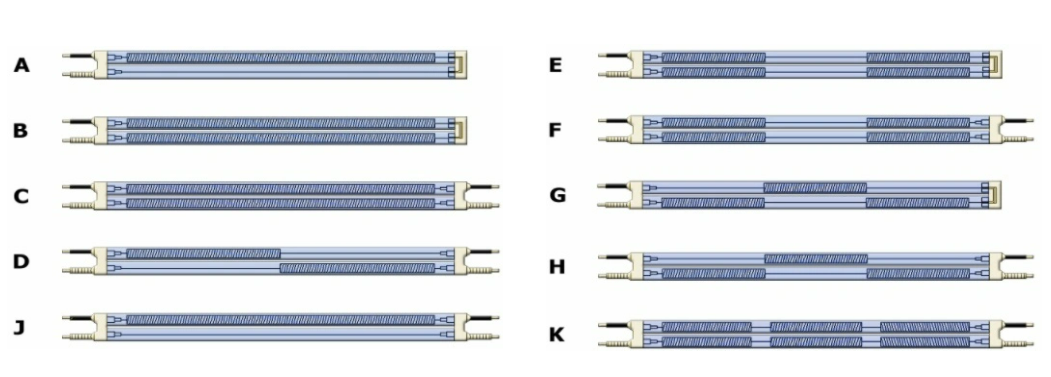

Different construction type for twin tube medium wave IR heaters

Twin Tube IR Element with different filament configuration it can be made single side or two sides cable connection, and different heating channel. this allows an extraordinary flexibility both in term of heated area modularity and cables position. In the picture below there are represented some of the most common filament configuration.

These lamps are available in numerous standard lengths, Wattages, and Voltages for new applications or direct replacement for existing equipment. Contact us for more customized information!

These lamps are available in numerous standard lengths, Wattages, and Voltages for new applications or direct replacement for existing equipment. Contact us for more customized information!

| Glass tube |

99.9% pure fused silica quartz sealed |

| Filament material |

Ni-Cr or Fe-Cr-A1 |

| Filament temperature |

800 – 950°C |

| Peak wavelength |

2.4-2.7um |

| Average working life |

20000 hours |

| Cross section(mm) |

10, 11, 12, 13, 14, 15, 18, 20, 23*11, 33*15 |

| Max unit power |

25w/cm |

| Available length |

100-6000mm |

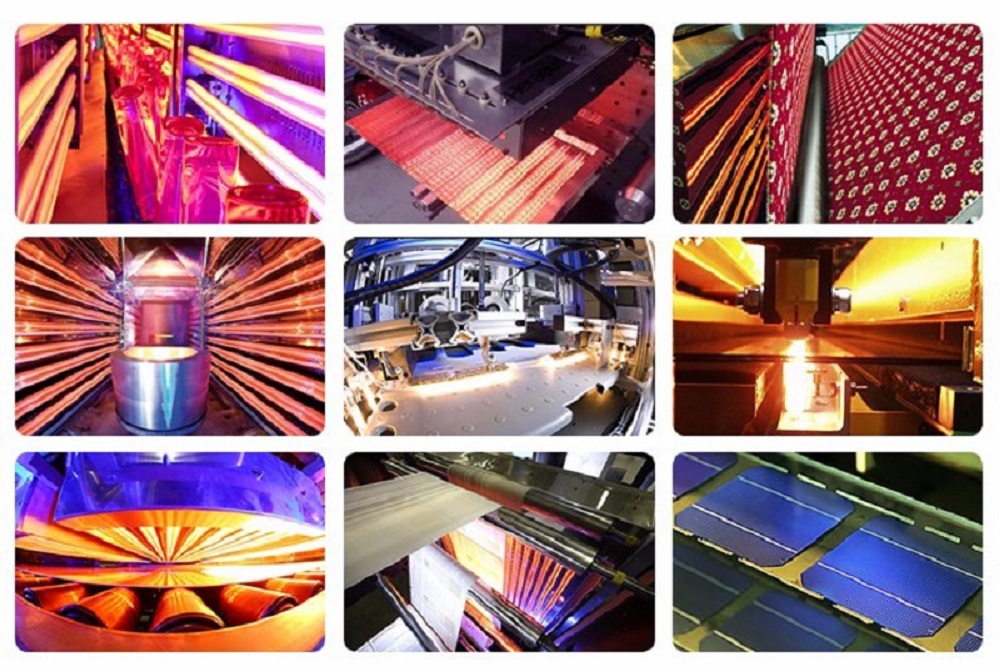

Typicall applications

- screen printing glass

- glass lamination

- laminated glass cutting

- mirror paint drying

- Curing Painted Surfaces

- Preheating Plastics

- Curing Powder Coatings

- Drying / heat setting textiles after dyeing or printing

- Supplemental heating

- Drying or inks for printing and silk-screening

- Preheating and curing wood coating

- Glass Curing

- Shrink Packaging Machines.

- Drying Textiles.

- Rubber Curing.

- Drying of paints

- Processing Plastic foils and sheet

ABOUT US

Anhui Quickly Industrial Heating Technology Co., ltd is a family of privately-owned companies focused on the development of infrared heating technology which dramatically reduces the time and space required for industrial heating and drying processes and provides quantum leaps forward in efficiencies for our global customers.

QUICKLY has experience in meeting the needs of a broad range of industries. Applications include paper, printing, textiles, non-woven products, liquid coating, powder coating, adhesives, laminating, welding, thermoforming, and annealing. We will continue to provide excellent process heating solutions for today's industrial needs, and for the challenges of tomorrow.

QUICKLY locates in Hefei, Anhui, China,with more than 70 Skilled workers with over 5 years of working experience on average. Dozens of our production employees have been in QUICKLY since the company was first established until today.

Why Choose US

Our IR Heater Lamps are under standard in CE & ROHS, we have strict quality control to make sure each IR lamp is perfect!By the way,we support the best service for you:

A:Sample Service

Some samples are free of charge, buyer shoulder the fright cost.

B:Customized Service

1. All of our Infrared Heater Elements are customized according to your unique practical request, professional technicians do one-to-one service for you and can customize 1pc Infrared Heater for your quality testing at the beginning.

2. We offer OEM services, we can print your logo on Infrared heating lamps as your requirements.

C:After-sale Service

Warranty Time of Short wave Infrared heat lamp: 5,000 hours

Warranty Time of Carbon Fiber Infrared heat lamp: 10,000 hours

Warranty Time of Medium wave Infrared heat lamp: 20,000 hours

During the warranty time, any non-man-made quality issue, once confirmed, we will sent the new replacement immediately without any charge.

FAQ

1. Are you a factory or trading company?

Quickly is a factory, we are professional manufacturer of infrared heater for more than 10 years.

2. Where is your factory? Can I visit your factory?

We're in Hefei city,Anhui Province of China. You are warmly welcome to our factory, we will be happy to show you our production, QC, warehouse, etc.

3. Can I have samples? Is it free?

Yes, we are happy to offer samples for you to check and test. Depends on sample quantity and product model, we will

confirm with you whether it's free sample or not.

4. What is your term of delivery?

We accept FOB, CIF, EXW etc. Please choose the one which is the most convenient and cost effective for you.

5. What about the lead time for mass production?

It depends on the order quantity and the season you place the order. Generally speaking, the lead time of MOQ is about

7-15 days. We suggest that you start inquiry at least two months before the date you would like to get the products at your country.

6. Do you offer guarantee for the products?

Yes, it must be. We guarantee 2 years for heaters and 5000-8000 hours for infraraed heater.

7. What type of payment do you accept?

T/T.WEST UNION.PAYPAL.CREDIT CARD.

8. Is it OK to print my logo on product?

Yes, it's possible. But please kindly note we have MOQ request for different products.

9. Can you do the design for us?

Yes. We have a professional team having good experience in box design and manufacturing. Just tell us your idea and

we will help to carry out your ideas into perfect packing boxes. It does not matter if you do not have someone to complete

files. Send us high resolution images, your logo and text and tell us how you would like to arrange them. We will send you

finished files for confirmation.