|

Product Name

|

SS-V007

Sofia

|

|

Slab Size

|

Slabs size:

3000x1400mm,3000x1600mm, 3200x1400mm, 3200x1600mm etc.

Cut-to-size: 1200x600mm, 600x600mm,600x300mm,

600x400mm, 300x300mm,800x800mm;etc.

Counter top: 48*26".

70*26", 78*26", 96"x 26", 108"x 26"

Island: 72"x

36", 96"x 36", 96"x 40", 108"x 44"

Vanity top: 22"x

25", 22"x 31", 22"x 37", 22"x 49",

22"x 61", 22"x 73"

|

|

Thickness

|

12mm,15mm,18mm,20mm,30mm,etc.

|

|

Surface Finish

|

Polished or Honed or

Customized

|

|

Water Absorption

|

<0.05%

|

|

MOQ

|

100 Square meters

|

|

Quality Control

|

Polished degree:90 degree

or up.As customs' requirement

Thickness tolerance:

/-1mm

All products checked by

experienced QC and then pack

|

|

Application

|

Countertop, worktop,

table top, Bar Top, Bathtub, Sink,etc.

|

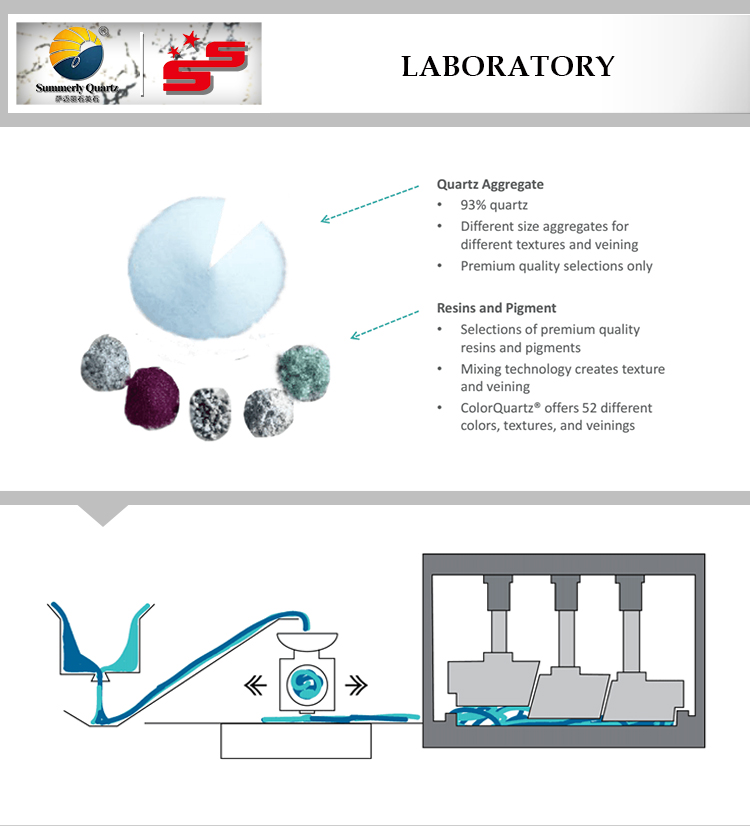

Quartz countertops are manufactured with a

combination of hard quartz crystals and durable resin polymers that make them

extremely resilient. Low maintenance requirements make quartz countertops

appealing to many homeowners. All

designs are custom made since it is an engineered Quartz, so the selections are

diverse, and you are guaranteed to find the colors you are looking for.

Conversely, Granite and Marble you would have to choose from Nature’s menu. But selection is limited

compared to Quartz.

Quartz countertops have grown in popularity

as homeowners discovered what the earliest quartz pioneers knew - when the

natural mineral quartz is improved upon by man's ingenuity, quartz countertops

can compete with other natural stone countertops in every way. As a manmade

material, not only is quartz widely available, it can be easily manufactured

for unique sizing and unique shapes, including circles and curves.

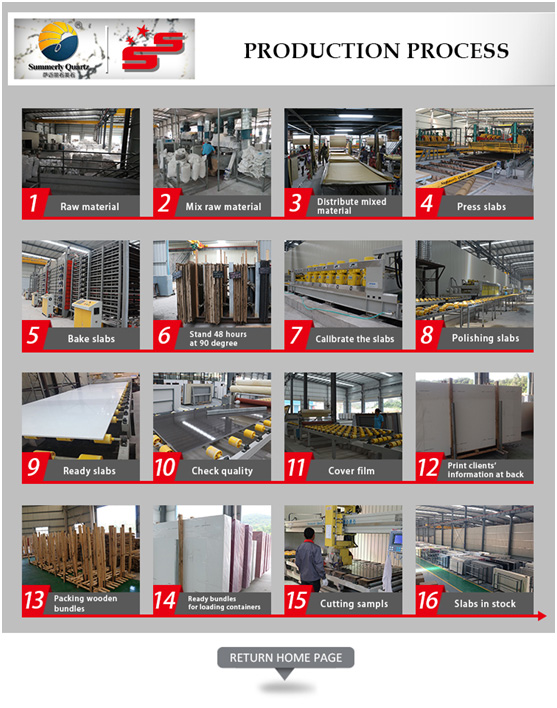

Production Engineering:

1. The process begin with a rigorous

inspection of raw materials.

2. Feeding natural quartz raw material and

polymer resins and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring

them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a

special vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and

heated for a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing

and polishing surface to perfect finished.

7.Finally, the quartz stone slabs passed

through quality inspection and packed with a plastic film.

Packing wooden

crate (slab) wooden box (tiles/

countertop)

Lboratory: