|

Item No

|

SS3868 South Africa Dark Brown

|

|

Color

|

Dark Brown

|

|

Product

|

Big slab, Countertop, Table top, Vanity top,

|

|

Thickness

|

12 mm, 15 mm, 18 mm, 20 mm, 30 mm

or custom- made is available

|

|

Size

|

3000x1400mm,3000x1600mm, 3200x1400mm, 3200x1600mm etc.

|

|

Thickness

|

12 mm, 15 mm, 18 mm, 20 mm, 30 mm,etc.

|

|

Finishing

|

Polished, Honed, etc

|

|

Density

|

2364 Kg/M3

|

|

Mohs′ Hardness

|

7

|

|

Tone & Figure

|

< Consistent

|

|

Quality Control

|

Confirm Every Details Before Make the Rough Production

Thickness tolerance: ±0.5mm, ±1mm, 90 degree up polished

All products were checked by experienced QC before packed

|

|

Packing

|

Plastic inside strong seaworthy

wooden bundle outside

|

Artificial

Quartz is made from over 93% of quartz. The natural quartz in Artificial Quartz

delivers distinctive depth, brilliant clarity, glimmering radiance and a cool,

solid feel unique to natural stone.Quartz has begun to top the lists of

countertop options for designers and homeowners alike. Anyone that wants a

durable, low maintenance, and attractive countertop material is likely to

consider quartz. Quartz is a manufactured surface that is made by mixing 93%

ground natural quartz with 7% polymer resins. The result is a material that

still looks natural. If you are remodeling a bathroom or considering using

quartz for your kitchen countertops, quartz is good choice .

Quartz

doesn't just look great, but it can be easy to clean as well. Whether it's a big

spill or everyday dust, there's no trick to cleaning this smooth surface.

Simple soap and water usually does the trick. Material that has hardened

on the surface can be removed with a gentle cleansing scrub. Abrasive scrubs

and cleansers that contain bleach and harsh chemicals should be avoided, as

these can dull the surface and break down the bonds within the quartz stone.

Application:

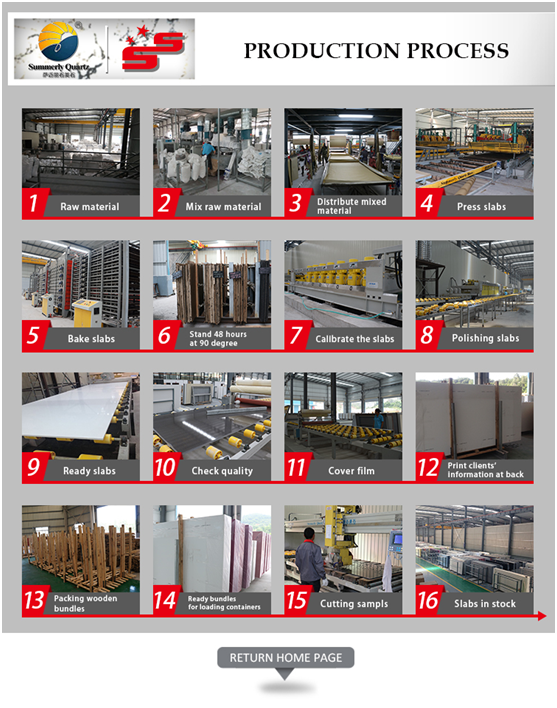

Production Engineering:

1. The process begin with a rigorous inspection of raw

materials.

2. Feeding natural quartz raw material and polymer resins

and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring them into a

mold and form them into slab size.

4. Pressing: Then the slab is compacted by a special

vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and heated for

a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing and polishing

surface to perfect finished.

7.Finally, the quartz stone slabs passed through quality

inspection and packed with a plastic film.

Packing wooden crate (slab) wooden box (tiles/ countertop)