|

Name

|

Artificial Quartz Stone

|

|

Model No

|

SS6312

Snow Vein

|

|

Sizes

|

3000x1400mm,3000x1600mm, 3200x1400mm,etc.

|

|

Thickness

|

12mm,

15mm, 18mm, 20mm, 30mm.etc.

|

|

Thickness Difference

|

1.0mm

|

|

Surface finishes

|

polished, honed, or others

|

|

Hardness

|

7 Mohs

|

|

Temperature Resistance

|

≥300ºC

|

|

Quality control

|

Color difference control,Safe packing,

Thickness tolerance: /-1mm

All products are checked by experienced QC piece by piece and then pack

|

|

Packing

|

Strong

wooden crates with fumigation.

|

|

Delivery

|

T/T, irrevocable L/C at sight, Western Union.

|

|

Usage

|

kitchen countertop, bathroom tops, washing

room tops, window sills top,etc.

|

Quartz countertop

offers the natural beauty of quartz with up to six times the strength and

durability of granite. Approximately 93 percent of Quartz countertop is mined

quartz crystals, one of nature’s hardest materials. The quartz is combined with

high-quality polyester resins and pigments producing a engineered stone without

the high-maintenance while making it resistant to heat, scratches, and stains.

The hard surface of

Quartz is non-porous and very resistant to staining, even better than

marble. Quartz counters can resist oil,

coffee, wine, juice and most other common kitchen spills. However, when

cooking, use trivets or heating pads to guard the countertop surface against

direct exposure to hot cookware or coffee pots. Although quartz is resistant to

stains, it is best to wipe up spills immediately to prevent possible stains.

When chopping vegetables, slicing bread or preparing other foods with sharp

utensils, use a cutting board to prevent scratches.

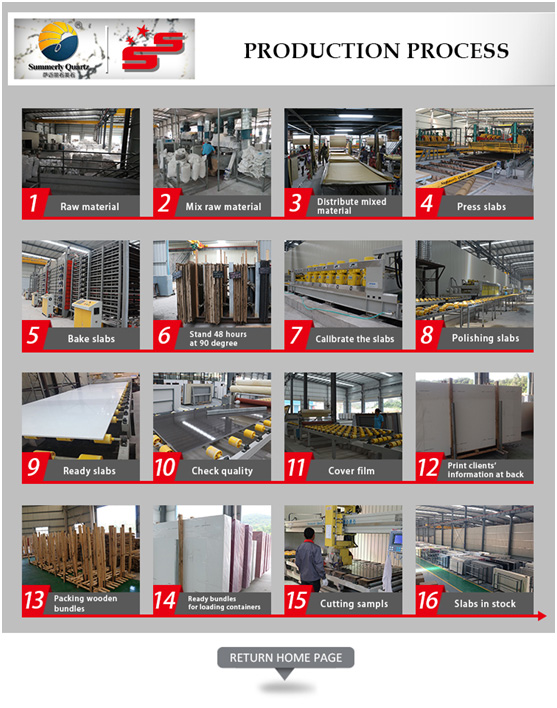

Production Engineering:

1. The process begin with a rigorous

inspection of raw materials.

2. Feeding natural quartz raw material and

polymer resins and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring

them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a

special vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and

heated for a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing

and polishing surface to perfect finished.

7.Finally, the quartz stone slabs passed

through quality inspection and packed with a plastic film.

Packing wooden

crate (slab) wooden box (tiles/

countertop)