Radio Shuttle System

HUAYIDE Radio Shuttle Pallet Rack System is a semi-automated system conjunction with forklift trucks for storage of goods with low variety but high volumes per SKU. This system is highly recommended in manufacturing businesses, especially those fast moving consumer goods, food, beverage and cold chain industries.

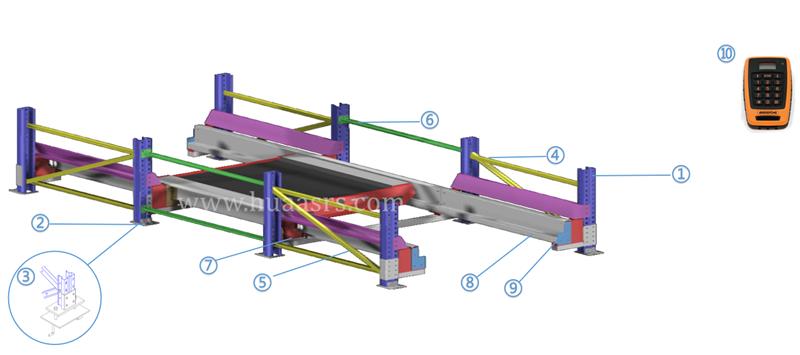

System Components:

① Upright

② Footplate

③ Adjustable Foot Stand

④ Horizontal Strut

⑤ Diagonal Strut

⑥ Row Spacer

⑦ HUADE Beam with Rail Bracket

⑧ Rail

⑨ Back Stop

How does it works?

The shuttle rack system consists of two major components: High Density Open Face Pallet Racking System and Battery-powered radio shuttles. Forklift places a shuttle at the end of lane before selecting an operation mode by using the remote controller. The lanes are fed pallets by the programmable mobile shuttles. The number of shuttles can be adjusted to match throughput demand. Shuttle retrieves, deposits, and reshuffles the pallet in the racking storing lanes and moved by means of traditional forklift.This system solution is also available for cold storage with temperatures of up to -30°C.

High Density Pallet Racking System

An important group of storage solutions used for warehouse fulfillment tasks, apart from those allowing direct access to each pallet. This high-density rack group includes solutions with Drive-In/Drive-Thru Rack, Gravity Flow Rack, Shuttle Storage Rack System, Mobile Racking.

Although each of these rack systems naturally has its own unique features, they do share a number of common characteristics.

The fact that they are compact systems means they make better use of space. However, they are best used though when there are a large number of pallets with the same SKU, which means one channel should contain only one SKU.

Raido Shuttle (HUADE Pallet Shuttle)

The radio shuttle (also known as pallet shuttle) system is based on both FIFO and LIFO inventory management principles. It is equipped with rechargeable iron ion battery, if the racks are open on one end, the storing and picking of the pallets is done from the same end which means that the first pallet to go in will be the last one to come out (LIFO). If the racks are open from opposite ends, then the storing and picking will be done on opposite ends without any interference. This means that the first pallet to go in will be the first one to come out (FIFO).

Shuttle Technical Specifications:

| Item |

Basic Parameters |

| Applicable Pallet Size |

1×1.2m, 1.1×1.2m, 1.2×1.2m |

| Loading Capacity |

1000kg / 1500kg |

| Driving |

Speed: Empty 50m/min, Full Load 40m/min |

| Acceleration: ≤0.3m/s² |

| Motor: Brush servo motor 24VDC 650W |

| Servo Drive: AB50A100 |

| Lifting |

Hoisting Height: 40mm |

| Motor: Brush motor 24VDC370W |

| Position Method/ Accuracy |

Driving: Photoelectric sensor

Pallet positioning: Photoelectric sensor

Lift positioning: Proximity switch |

| Power Supply |

Lithium iron phosphate power battery |

| Battery |

24V, 55A, using time 8H, charging time 4H, Charging time: 1000 |

Add-on

Charging Station

Re-charge the battery by placing it into our special box, which automatically connects the battery to the power

Maintenance Cart

Manual truck for maintenance or recovery of shuttle from rack lane

Remote Controller

Multi function

Multi language

Resistant up to -30℃

Features of Radio Shuttle System

- Increase storage density & Optimize all available storage space: Storage, loading and unloading stages

- Lower level of risk to warehouse equipment: reduce damage to products and the system

- Stock rotation according to established FIFO or LIFO criteria.: allow for off-shift staging, so pallets can be sequenced for loading

- Suitable for all industrial sectors, particularly recommended for the Food & Beverages with few varieties and large batches

- No more rely on specialized forklift trucks

- Able to be Managed by WMS: smart positioning & inventory control system ensure elimination of labour errors

-

Applications

- Food Production: Goods of low SKU count but high volumes per SKU

- Beverage Production and Distribution: Goods of low SKU count but high volumes per SKU

- Meat Processing

- Cold & Frozen Storage: Decrease low temperature operation time, improve working efficient and safety

-

Contact Us Today

There are a number of pallet shuttle system providers out there. The biggest advantage of us is we were the first one to import Italy brand AutoSAT shuttle to China market, provided racking system and special rails for them. We started our own shuttle mass production since 2003.

Whether your next step is to gather more information or request a quote, consider HUAYIDE LOGISTICS TECHNOLGY. We are a highly experienced system integrator, the rack manufacturing business since 1993.

As a highly knowledgeable and experienced supplier in designing, engineering, and installing such semi-automated racking solution. We will make sure your system is the best fit for your SKU profiles and space. We work with you to provide a turnkey system. From engineering, design, products procurement, subcontractor management, install, and permitting after-sale support, HUAYIDE handles it all for you.

We’d appreciate the opportunity to help you further, whether that be more information or a quote. Fill in the contact form or call +86 18652003451 to get in touch with a HUAYIDE representative.