1 Product Parameters

|

Specifications

|

|

Type

|

Rock Wool Sandwich Wall Panel

|

|

Density

|

50~200 kg/m³

|

|

Thickness

|

50/75/100/120/150mm

|

|

Metal skin thickness

|

0.4~0.8mm

|

|

Panel Effective Width

|

1000mm for wall and 950/1000mm for roof

|

|

Skin material

|

PPGL, PPGI, Stainless, Steel, Aluminum coil

|

|

Pre-painted

|

PE/SMP/HDP/PVDF etc.

|

|

Fireproof Grade

|

A

|

|

Thermal Conductivity

|

0.04~0.055

|

|

Temperature Range

|

800℃

|

|

Length

|

Max 11.9m or Customized.

|

|

Customized design is welcomed.

|

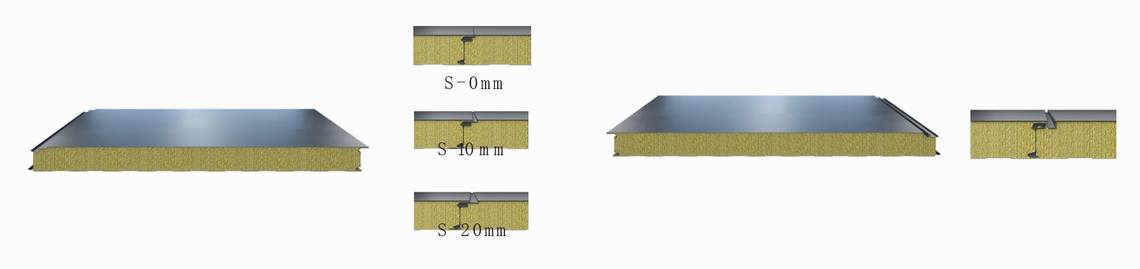

2 Product Features

Fire protection: As A class A non-combustible material, the rock wool core made of natural rock has a fire resistance limit of more than 4 hours, adding a layer of solid fire protection shield to the building. High density and high strength: Density between 80kg/m³ -150kg /m³, commonly used 120kg/m³, compressive strength ≥150KPa, and two layers of steel closely combined, cope with extreme weather calmly.

Excellent thermal insulation effect: Slender and flexible rock wool fiber, pure rock wool core material thermal conductivity ≤0.043W/ (m · K), high-quality PU edge can be ≤0.025W/ (m · K), keep indoor warm in winter and cool in summer.

Good sound insulation performance: Rockwool composite board has a porous structure, effectively absorb and reflect sound waves, reduce the interference of external noise to the room. Suitable for places with high sound insulation requirements, such as hospitals, schools, conference rooms, recording studios and so on

Green environmental protection: Inorganic materials are pollution-free, green production process, recyclable

Easy installation: Prefabricated components, an average of 600㎡ -800 ㎡ per day, the construction period is greatly shortened.

Allowable vertical load and heat transfer coefficient of PROPANEL new model fireproof rock wool wall sandwich panel with pu sealing (allowable deflection f ≤ L/240)

|

Thickness (mm)

|

Heat transfer (W/m2k)

|

Weight (kg)

|

Load P=KN/m2

|

0.60

|

0.80

|

1.00

|

1.20

|

1.50

|

|

50

|

0.75

|

15.74

|

L(m)

|

3.78

|

3.31

|

2.98

|

2.71

|

2.41

|

|

75

|

0.53

|

18.68

|

L(m)

|

4.83

|

4.21

|

3.76

|

3.42

|

3.01

|

|

100

|

0.41

|

21.62

|

L(m)

|

5.77

|

5.02

|

4.47

|

4.04

|

3.55

|

|

150

|

0.31

|

27.51

|

L(m)

|

7.53

|

6.54

|

5.82

|

5.26

|

4.61

|

Note:0.5mm outer steel sheet and 0.4mm inner steel sheet.

3 Production Procedure of Rock Wool Sandwich Wall Panel

The Rock Wool Sandwich Wall Panel is crafted through a precise production process, delivering exceptional product features like fire resistance, thermal insulation, and durability. Starting with stainless steel coils and color-coated galvanized coils as upper and lower substrates, the panels gain corrosion resistance and a sleek finish. These coils are decoiled efficiently, followed by film application to protect the steel sheets from scratches. The sheets are then corrugated for enhanced strength and load-bearing capacity, making them ideal for structural use.

Next, the steel sheets are preheated to ensure strong adhesion, while rock wool strips—the core material—are prepared for their superior fireproofing, insulation, and soundproofing properties. The rock wool is cross-butted to form a seamless core, maximizing thermal efficiency. A spraying section enhances surface durability, followed by an optional polyurethane side sealing for airtightness and moisture resistance, or no sealing based on project needs.

The panels undergo double-crawler curing, ensuring a robust bond between layers with even heat and pressure. They are then cut into pieces with precision for perfect sizing, stacked carefully to avoid damage, and automatically packaged for secure shipping. This process creates a high-performance panel suited for industrial, commercial, and residential applications, offering energy efficiency, safety, and longevity in a single solution.

4 Project cases of Rock Wool Sandwich Wall Panel

Project cases of Rock wool Wall Sandwich Panel--6000 square meters of BD project in the United States in 2018

Project cases of Rock wool Wall Sandwich Panel--Indonesian electronics factory in 2005 9000 square meters

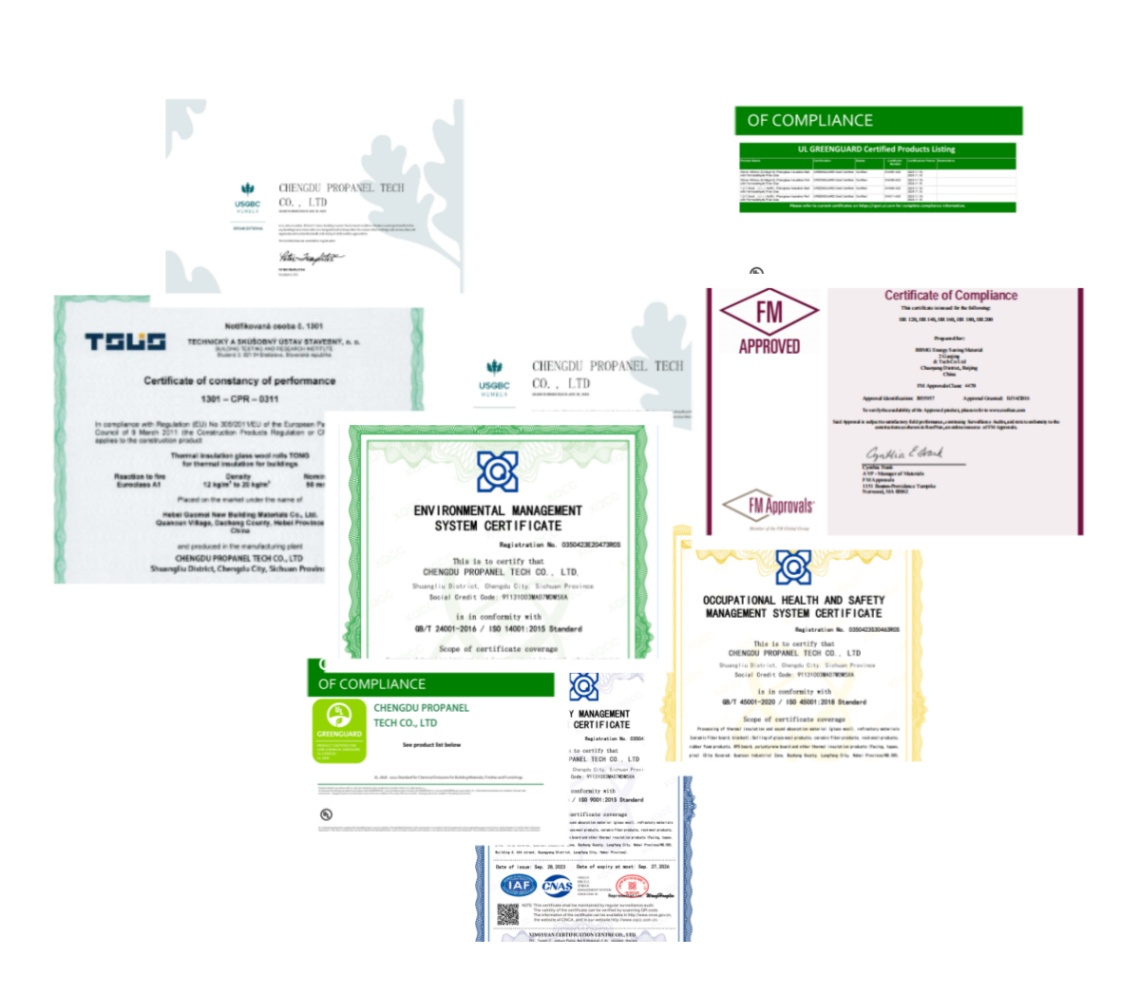

5 Propanel's Honors and Certification

Propanel's rock wool sandwich panel has successfully obtained international authoritative certifications such as CE, FM, and UL with its excellent quality. Certified by CE, it complies with the safety, health, and environmental protection standards of the European Union and can freely circulate in the European market. FM certification indicates outstanding performance in fire resistance and wind resistance, and can effectively cope with challenges in various industrial and commercial environments. UL certification further confirms that the product meets the standards in electrical safety, fire resistance, and material stability, meeting stringent requirements. These certifications are a testament to strength, highlighting the reliability and high quality of rock wool sandwich panels on a global scale. Whether in the field of building insulation or fire safety, it can provide customers with reliable protection.