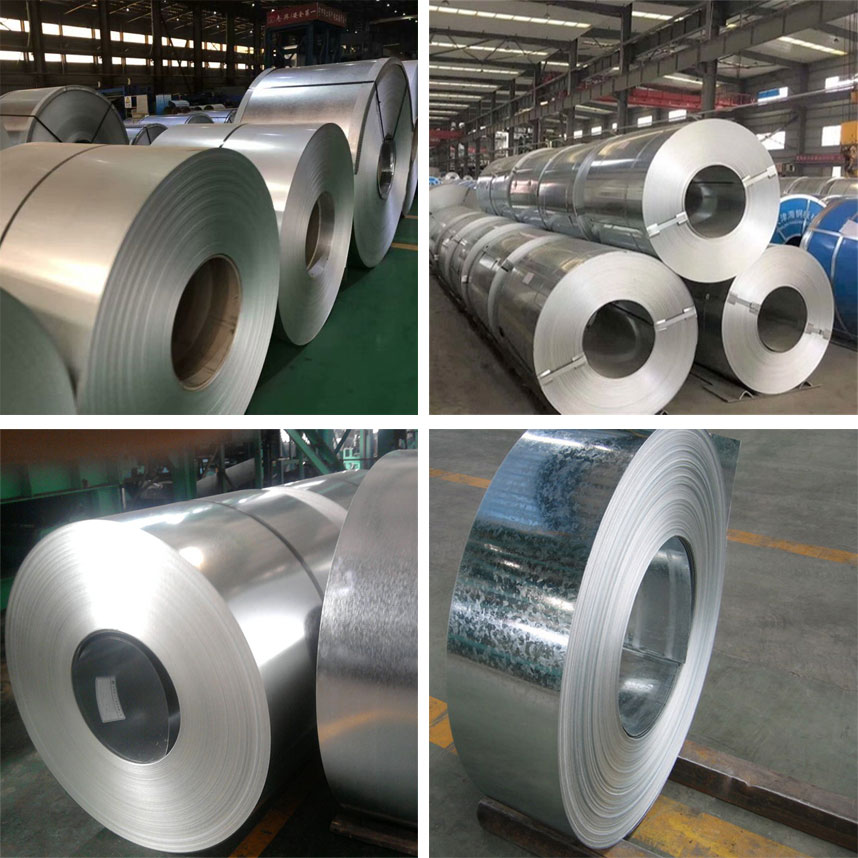

SGHC DX51D Hot Dip Zinc Coating Galvanized Steel Coil

Product Details

|

Type of Coating

|

Hot Dipped Galvanized Steel (HDGI)

|

SurfaceTreatment

|

DRY,OIL,Chromate,Anti-fingerprint,Gr-free,etc

|

|

Surface Structure

|

Normal spangle coating (NS), minimized spangle coating (MS), spangle-free(FS)

|

Thickness

|

0.125mm To 3.5mm

|

|

Zinc Coating

|

40g/m2 To 275g/m2

|

Width

|

600mm To 1500mm

|

|

High Light

|

DX51D PPGI Steel Coil

PGI Steel Coil

3.5mm PPGI Steel Coil

|

|

Standard

|

ISO,JIS,AS EN,ASTM

|

|

Grade

|

Q195 Q235 Q345

|

|

SGCC SGCH SGC340 SGC400 SGC440 SGC490 SGC570

|

|

SGHC SGH340 SGH400 SGH440 SGH490 SGH540

|

|

DX51D DX52D DX53D DX54D DX55D DX56D DX57D

|

|

S220GD S250GD S280GD S320GD S350GD S400GD S500GD S550GD

|

|

SS230 SS250 SS275

|

|

Width

|

600mm to 1500mm

|

|

Thickness

|

0.125mm to 3.5mm

|

|

Zinc coating

|

40g/m2 to 275g/m2

|

|

Coil weight

|

3 tons to 6 tons

|

|

Coil ID

|

508mm or 610mm

|

|

Surface treatment

|

Unoil,Dry,Chromate Passivated, Non-chromate Passivated

|

|

Spangle

|

Regular Spangle, minimum Spangle,Large Spangle, Zero Spangle

|

|

Capacity

|

1,500,000MT/year

|

|

Delivery

|

20-30 Days

|

Features

1. Galvanized steel plate is widely used in various environments and has a long anti-corrosion life. The anti-corrosion life is different in different environments.

2. The treatment cost is low, and the anti-corrosion cost of galvanized steel plate is lower than that of other paint coatings.

3. Durable. In suburban environment, the standard galvanized antirust coating does not need to be repaired and can be maintained for more than 50 years. In urban or offshore areas, the standard galvanized antirust coating can be maintained for 20 years without repair.

Good reliability. The zinc coating and steel are metallurgically combined and become a part of the rigid surface, so the durability of the coating is relatively reliable.

FAQ

why our steel?

We are China well known steel sheet manufacturer and supplier. Cooperated with professional and strength manufacturer,we can provide metal products that meet your requirements.

whats the biggest advantage?

We saves you time and money. With our cold rolled steel sheet you can achieve greater yields, improved equipment usage and fewer work hours to manufacture your parts.

what services do we provide?

We can provide customized service including slitting,steel sheet & plating painting,hot dipped coating,finishing treatment,custom size options. Please feel free to send us your requirements,we will reply very soon.

How do we package the products?

Triple packaging (anti-rust paper + plastic film + corrugated paper), fixed with fumigated wooden pallets, which can effectively protect the product from corrosion during ocean transportation.

When do we deliver the products?

Standard products within 15 days, customized products within 20-30 days.

Our Service

Heavy Gauge Slitting

Steel Coil Slitting

Steel Sheet Cut-to-Length

Electro cold Rolled & Hot Dipped Coating

Steel Sheet & Plate Painting

Finishing Services