- Wear resistance performance

- Outstanding wear reduction effect: The ultra-high hardness lays a solid foundation for its excellent wear resistance. In practical applications, replacing metal components with zirconia ceramic shafts or square bars can significantly reduce wear. For instance, an automobile enterprise once used stainless steel for engine valve guides, which needed to be replaced every 3 months; after switching to zirconia ceramic rods, the wear rate dropped by 90%, and the service life was extended to 2 years.

- Assisted by self-lubrication and toughness: Zirconia ceramic shafts also have self-lubricating properties. When used as transmission and support shafts in mechanical equipment, they can reduce operational resistance and further reduce wear caused by friction. In addition, their fracture toughness reaches 6 - 9MPa·m¹/², which is three times that of traditional alumina ceramics. This avoids brittle fracture and subsequent abnormal wear caused by impact during use, ensuring long-term stable wear resistance.

- Stable in harsh environments: It can withstand a high temperature of 1000℃ and has good thermal shock resistance. Even in high-temperature working conditions where the temperature fluctuates by 30℃ per hour, its structure and performance remain stable without softening or deformation that would lead to increased wear. At the same time, it is resistant to corrosion by acids, alkalis, salts and other media. In corrosive environments such as chemical industry and gold mining, it will not be corroded to cause surface damage and reduced wear resistance, so it can maintain long-term effective operation in harsh and high-wear scenarios such as gold mining conveying systems and chemical fluid transmission equipment.

- Additional advantages of square zirconia ceramic bars

-

-

Square zirconia ceramic bars, as a special-shaped type of zirconia ceramic bars, not only have the above hardness and wear resistance but also have unique advantages in installation and application. Their square structure can achieve more stable positioning and connection when used as components such as guide rails and positioning rods. And after precision processing, their surface roughness can reach Ra 0.1μm. The smooth surface can reduce friction with matching parts, thus reducing wear loss during transmission and movement, and is very suitable for precision mechanical equipment with strict requirements on shape and wear resistance.

Technical Parameters

| Item |

Unit |

Zirconia ceramic |

99% alumina ceramic |

96% alumina ceramic |

95% alumina ceramic |

Steatite ceramic |

Mullite ceramic |

Cordierite ceramic |

| Bulk density |

g/cm3 |

6 |

3.8 |

3.7 |

3.6 |

2.8 |

2.2 |

2.3 |

| Water absorption |

% |

0 |

0 |

0 |

0 |

0 |

12 |

12 |

| Thermal Conductivity |

(w/m.k) |

10 |

19-30 |

16-28 |

14-24 |

2-3 |

2-6 |

1.3-1.8 |

| Resistance to thermal shock,Minimum |

TK? |

70 |

150 |

140 |

140 |

80 |

150 |

300 |

| Withstand voltage,Minimum |

KV |

15 |

20 |

18 |

18 |

20 |

25 |

- |

| Flexural strength |

Mpa |

1000 |

300 |

280 |

240 |

120 |

120 |

30 |

| Sintering temperature |

℃ |

1500 |

1670 |

1600 |

1600 |

1250 |

1250 |

1250 |

| Maximum working temperature |

℃ |

1200 |

1500 |

1200 |

1200 |

800 |

1000 |

1000 |

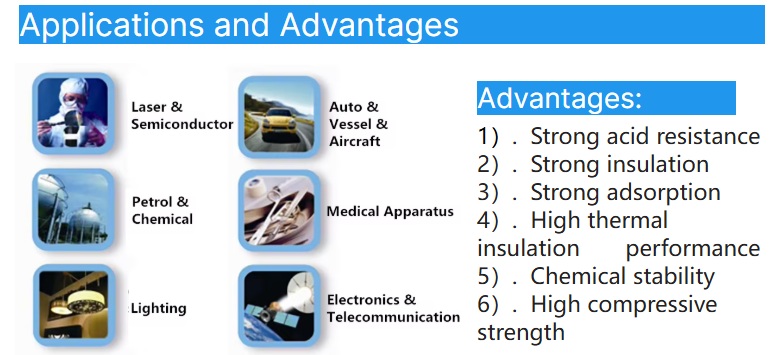

Application

Specifically used for high-temperature and high-voltage insulation parts, circuit substrates, high-temperature devices, etc. As the main representative of precision ceramic materials, it is widely used in industries such as semiconductors, petrochemicals, and electronics.

Advantages

1. we support OEM and ODM;

2. We have a professional R&D team and technical support;

3. We provide real-time logistics update information;

4. We support 24-hour online service;

5. We support T/T,L/c payment;

6. We have a professional QC team to check the quality before delivery.

Certificate

FAQ

1. How can you get quotation?

Please kindly send me your drawing with technic requirement and demand quantity.

If you don't have the drawing, please kindly courier samples to us. we will quote our best price in 24 hours.

2. How can you get samples?

We can supply free samples if we have them in stock. If we haven't produce the products, we can supply some free samples after getting tool fee. Please take note that the courier fee should be at destination.

3. What’s the lead-time for samples and batch orders?

It is 18days for supplying samples. It is around 25days for batch orders.

4. Can I visit you?

Sure. If you're a volume buyer and would like to visit our in-house products and production line, please contact us to make an appointment.