• High Hardness and Wear Resistance: With a Mohs hardness of about 8.5, it has excellent wear resistance and erosion resistance, which can significantly extend the service life.

• High Temperature Resistance: It can withstand high temperatures of up to 1600°C and maintain stable performance in high-temperature environments.

• Good Chemical Stability: It has excellent resistance to acids, alkalis, and solvents, and is not easily corroded by chemical substances.

• Good Thermal Conductivity: It has good thermal conductivity, and is not easy to crack and deform due to thermal cycling.

• High Precision: It can be manufactured with high precision, with an inner hole diameter of more than 0.8mm, and the shape can be customized according to customer needs.

Technical Parameters

| Item |

Unit |

Zirconia ceramic |

99% alumina ceramic |

96% alumina ceramic |

95% alumina ceramic |

Steatite ceramic |

Mullite ceramic |

Cordierite ceramic |

| Bulk density |

g/cm3 |

6 |

3.8 |

3.7 |

3.6 |

2.8 |

2.2 |

2.3 |

| Water absorption |

% |

0 |

0 |

0 |

0 |

0 |

12 |

12 |

| Thermal Conductivity |

(w/m.k) |

10 |

19-30 |

16-28 |

14-24 |

2-3 |

2-6 |

1.3-1.8 |

| Resistance to thermal shock,Minimum |

TK? |

70 |

150 |

140 |

140 |

80 |

150 |

300 |

| Withstand voltage,Minimum |

KV |

15 |

20 |

18 |

18 |

20 |

25 |

- |

| Flexural strength |

Mpa |

1000 |

300 |

280 |

240 |

120 |

120 |

30 |

| Sintering temperature |

℃ |

1500 |

1670 |

1600 |

1600 |

1250 |

1250 |

1250 |

| Maximum working temperature |

℃ |

1200 |

1500 |

1200 |

1200 |

800 |

1000 |

1000 |

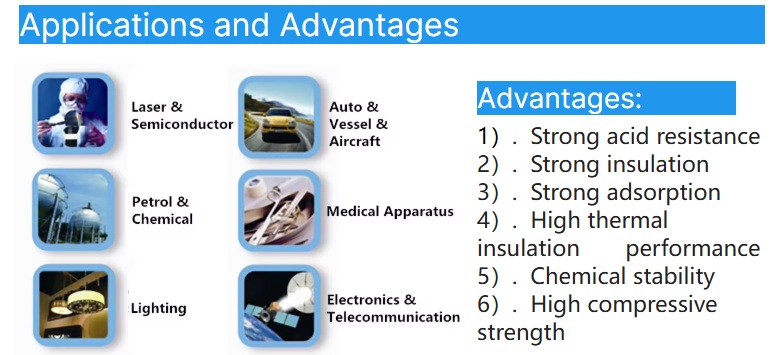

Application

• Chemical Industry: It is suitable for chemical processing applications that require resistance to corrosive substances.

• Metallurgy and Mining: It is used for handling abrasive media such as sandblasting and dust removal in the metallurgy and mining industries.

• Electronics and Electrical Engineering: It is used in electronic and electrical engineering components that require high electrical insulation and thermal stability.

Advantages

1. we support OEM and ODM;

2. We have a professional R&D team and technical support;

3. We provide real-time logistics update information;

4. We support 24-hour online service;

5. We support T/T,L/c payment;

6. We have a professional QC team to check the quality before delivery.

Certificate

FAQ

1. How can you get quotation?

Please kindly send me your drawing with technic requirement and demand quantity.

If you don't have the drawing, please kindly courier samples to us. we will quote our best price in 24 hours.

2. How can you get samples?

We can supply free samples if we have them in stock. If we haven't produce the products, we can supply some free samples after getting tool fee. Please take note that the courier fee should be at destination.

3. What’s the lead-time for samples and batch orders?

It is 18days for supplying samples. It is around 25days for batch orders.

4. Can I visit you?

Sure. If you're a volume buyer and would like to visit our in-house products and production line, please contact us to make an appointment.