Core Performance Advantages

- Exceptional High-Temperature Resistance: Withstands continuous operating temperatures of 300–800℃ (varies by purity), adapting to UV lamp’s heat generation during long-term use.

- Superior Electrical Insulation: High breakdown voltage and insulation resistance, isolating electrodes from external components to prevent leakage and ensure safe operation.

- Corrosion Resistance: Resists erosion from ozone (a byproduct of UV lamp operation) and chemical vapors, avoiding material degradation and extending service life.

- Dimensional Stability: Low thermal expansion coefficient, maintaining precise fit with the lamp tube and electrodes even under temperature fluctuations.

- Good Thermal Conductivity: Quickly dissipates heat from electrodes to the external environment, protecting the lamp’s core components from overheating.

Technical Parameters

| Item |

Unit |

Zirconia ceramic |

99% alumina ceramic |

96% alumina ceramic |

95% alumina ceramic |

Steatite ceramic |

Mullite ceramic |

Cordierite ceramic |

| Bulk density |

g/cm3 |

6 |

3.8 |

3.7 |

3.6 |

2.8 |

2.2 |

2.3 |

| Water absorption |

% |

0 |

0 |

0 |

0 |

0 |

12 |

12 |

| Thermal Conductivity |

(w/m.k) |

10 |

19-30 |

16-28 |

14-24 |

2-3 |

2-6 |

1.3-1.8 |

| Resistance to thermal shock,Minimum |

TK? |

70 |

150 |

140 |

140 |

80 |

150 |

300 |

| Withstand voltage,Minimum |

KV |

15 |

20 |

18 |

18 |

20 |

25 |

- |

| Flexural strength |

Mpa |

1000 |

300 |

280 |

240 |

120 |

120 |

30 |

| Sintering temperature |

℃ |

1500 |

1670 |

1600 |

1600 |

1250 |

1250 |

1250 |

| Maximum working temperature |

℃ |

1200 |

1500 |

1200 |

1200 |

800 |

1000 |

1000 |

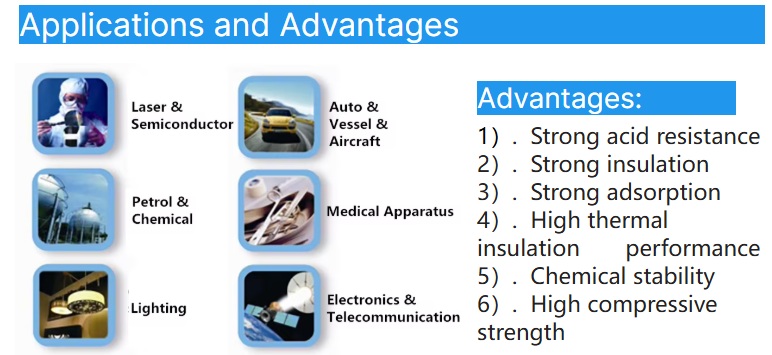

Application

- Water & Air Purification: Used in UV water purifiers, air disinfection equipment, and sewage treatment UV lamps, providing stable support and insulation.

- Industrial Curing: Applied in UV curing lamps for coatings, inks, and adhesives (e.g., printing, electronics manufacturing), adapting to high-temperature curing environments.

- Medical & Sanitation: Supporting components for UV disinfection lamps in hospitals, laboratories, and food processing plants, meeting strict hygiene and safety requirements.

- Semiconductor & Electronics: Used in UV cleaning lamps for wafer processing and circuit board manufacturing, ensuring pollution-free and reliable operation.

Advantages

1. we support OEM and ODM;

2. We have a professional R&D team and technical support;

3. We provide real-time logistics update information;

4. We support 24-hour online service;

5. We support T/T,L/c payment;

6. We have a professional QC team to check the quality before delivery.

Certificate

FAQ

1. How can you get quotation?

Please kindly send me your drawing with technic requirement and demand quantity.

If you don't have the drawing, please kindly courier samples to us. we will quote our best price in 24 hours.

2. How can you get samples?

We can supply free samples if we have them in stock. If we haven't produce the products, we can supply some free samples after getting tool fee. Please take note that the courier fee should be at destination.

3. What’s the lead-time for samples and batch orders?

It is 18days for supplying samples. It is around 25days for batch orders.

4. Can I visit you?

Sure. If you're a volume buyer and would like to visit our in-house products and production line, please contact us to make an appointment.