- Core Performance Advantages

- Outstanding insulation performance: It has a volume resistivity of over 1×10¹³Ω·cm at 100℃, and its DC breakdown strength can reach 30 - 40KV/mm. This excellent insulation property can effectively prevent leakage risks when the lamp socket is in contact with current during operation, which is especially crucial for high - voltage lighting equipment.

- Strong high - temperature resistance: Its maximum service temperature can reach 1650℃. Even when high - power lamps emit a large amount of heat during long - term operation, the socket will not deform, soften, or lose its performance. Moreover, it has good thermal shock resistance. After being kept at 800℃ for 30 minutes and cooled to room temperature repeatedly for 10 times, there will be no cracks or bursts.

- Excellent mechanical and corrosion resistance: It has a compressive strength of 2100MPa and a flexural strength of not less than 280MPa. It also has a Mohs hardness of 9.0, so it is wear - resistant and not easy to be damaged during installation and use. In addition, it can resist the erosion of strong acids and alkalis. It will not be corroded even when immersed in 10% hydrochloric acid or sodium hydroxide solution at 100℃ for 1 hour, which extends its service life in harsh environments.

- Stable dimensional stability: The 95% alumina ceramic has a low linear expansion coefficient. When the temperature is between 20 - 800℃, the coefficient is only 6.5×10⁻⁶ - 8×10⁻⁶/℃. This ensures that the socket will not have obvious dimensional changes due to temperature fluctuations, so as to maintain a stable fit with the lamp.

Technical Parameters

| Item |

Unit |

Zirconia ceramic |

99% alumina ceramic |

96% alumina ceramic |

95% alumina ceramic |

Steatite ceramic |

Mullite ceramic |

Cordierite ceramic |

| Bulk density |

g/cm3 |

6 |

3.8 |

3.7 |

3.6 |

2.8 |

2.2 |

2.3 |

| Water absorption |

% |

0 |

0 |

0 |

0 |

0 |

12 |

12 |

| Thermal Conductivity |

(w/m.k) |

10 |

19-30 |

16-28 |

14-24 |

2-3 |

2-6 |

1.3-1.8 |

| Resistance to thermal shock,Minimum |

TK? |

70 |

150 |

140 |

140 |

80 |

150 |

300 |

| Withstand voltage,Minimum |

KV |

15 |

20 |

18 |

18 |

20 |

25 |

- |

| Flexural strength |

Mpa |

1000 |

300 |

280 |

240 |

120 |

120 |

30 |

| Sintering temperature |

℃ |

1500 |

1670 |

1600 |

1600 |

1250 |

1250 |

1250 |

| Maximum working temperature |

℃ |

1200 |

1500 |

1200 |

1200 |

800 |

1000 |

1000 |

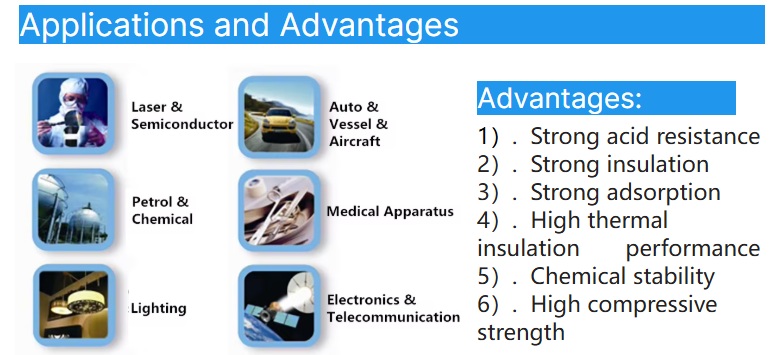

Application

Specifically used for high-temperature and high-voltage insulation parts, circuit substrates, high-temperature devices, etc. As the main representative of precision ceramic materials, it is widely used in industries such as semiconductors, petrochemicals, and electronics.

Advantages

1. we support OEM and ODM;

2. We have a professional R&D team and technical support;

3. We provide real-time logistics update information;

4. We support 24-hour online service;

5. We support T/T,L/c payment;

6. We have a professional QC team to check the quality before delivery.

Certificate

FAQ

1. How can you get quotation?

Please kindly send me your drawing with technic requirement and demand quantity.

If you don't have the drawing, please kindly courier samples to us. we will quote our best price in 24 hours.

2. How can you get samples?

We can supply free samples if we have them in stock. If we haven't produce the products, we can supply some free samples after getting tool fee. Please take note that the courier fee should be at destination.

3. What’s the lead-time for samples and batch orders?

It is 18days for supplying samples. It is around 25days for batch orders.

4. Can I visit you?

Sure. If you're a volume buyer and would like to visit our in-house products and production line, please contact us to make an appointment.