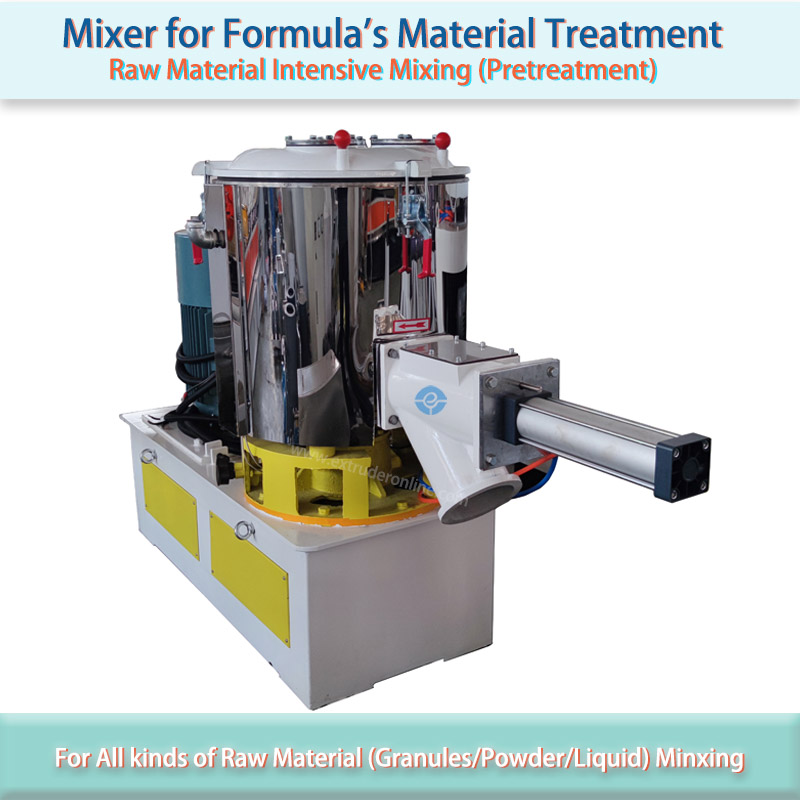

SHR 800A High speed mixer inverter controlled twin screw plastic extruder Auxiliary machine

HS CODE:8479.8200.90

This machine is for large output capacity production lines using for material mixing treatment.

1. Main Technical Parameter:

Model: SHR-800A

Volume:: 800L

Working Valume: 560L

Blade No.:: 3PCS

Blade Speed: 330/660RPM/Min.

Heating Way: Electrical Heating(Power: 12KW), Medium is conduction oil,Max. Temp.:300℃

Mixing Time: 6—10Min./Batch

Motor: Two-Speed AC Motor ( could be equipped chinese brand inverter)

Motor Model:: YD315L-8/4V1

Motor Speed: 740/1485RPM/Min.

Power: 83/110KW

Voltage: 380V/50Hz/3Phase

2、Electronic Controlling

Power Cabinet: 1set

Power: 380V/50HZ, AC;

Weight: 120Kg

3、Pneumatic controlling

Air source: Compressed air (source)0.39—0.49Mpa

Usage:SHR Serial high speed mixer is mainly used to mix, stir, dry and color for plastic material, rubber,

pharmacy, dre, food and commodity industries.

High speed mixer- twin screw plastic compounding extruder spare parts

High-speed-mixer-Production-Large-output-Duo-speed-motor-mixer-100L-1000L-HS-CODE:8479.8200.90

Technical parameters

|

Type

|

Total capacity

Total capacity

|

Effective capacity

|

Motor power

|

Heating power

|

Speed

|

Heating method

|

Material discharging

|

Dimension

|

|

SHR-5A

|

5L

|

3L

|

1.1kw

|

Null

|

1440rpm

|

Self-friction

|

By hand

|

620*300*730

|

|

SHR-10A

|

10L

|

7L

|

3kw

|

Null

|

1440rpm

|

1200*300*830

|

|

SHR-25A

|

25L

|

17L

|

5.5kw

|

Null

|

1440rpm

|

1200*350*850

|

|

SHR-50A

|

50L

|

35L

|

7/11kw

|

3kw

|

750/1500rpm

|

Electricity heating

|

Pneumatic

|

2100*700*1100

|

|

SHR-100A

|

100L

|

75L

|

14/22kw

|

6kw

|

650/1300rpm

|

2100*800*1500

|

|

SHR-200A

|

200L

|

150L

|

30/42kw

|

6kw

|

475/950rpm

|

2400*850*1580

|

|

SHR-300A

|

300L

|

225L

|

40/55kw

|

6kw

|

475/950rpm

|

2800*1080*1680

|

|

SHR-400A

|

400L

|

300L

|

47/67kw

|

9kw

|

430/860rpm

|

3160*1150*1760

|

|

SHR-500A

|

500L

|

375L

|

55/75kw

|

9kw

|

430/860rpm

|

3160*1150*1880

|

|

SHR-800A

|

800L

|

600L

|

83/110kw

|

12kw

|

370/740rpm

|

3385*1380*2750

|

|

SHR-1000A

|

1000L

|

750L

|

110/160kw

|

15kw

|

325/650rpm

|

3460*1380*2900

|

Purpose: It's a pretreatment machine for different raw material in the formula, for plastic granules raw materials mixing. Through different ingradients blading and self-friction let the materials coated each other and reached into the processing request.

Suitable for:

The user use this equipment for the formula’s different raw material mixing, let all kinds of the formula’s material mixed even, as sometimes the use will use different kinds of the raw material, like to say plastic granules, Filling powder(CaCo3/BaSO4/Talcum,Etc.), chips (WAX/Steric Acid and so on) and liquids(oil and others).

Use this device can mix all kinds of the raw material fully, and let them get together or wrap each other, then follow into next step: feeding them into the plastic extrusion machine line.

CAUTION:

WRONG OPERATION WILL DAMAGE THE OPERATOR AND MACHINE, PLEASE READ THE GUIDE CAREFULLY FIRST!

Application & Features:

- For plastics, rubber, daily chemical industry and laboratory materials mixing, stirring, dry blasting, painting and other craft.

- Dual sealing has been set by the pot cover.

- It has various of heating method: self-friction, electric heating (with or without conduction oil added) and other special heating methods.

- Material discharge methods have two kinds: automatic temperature control or manual control.

- Stainless steel casting blade which has refined through the static and dynamic balance test.