High Quality Single Flange Track Roller Single Lip Bottom Roller OEM Bulldozer and Harvester Parts

1. Our Advantages

-

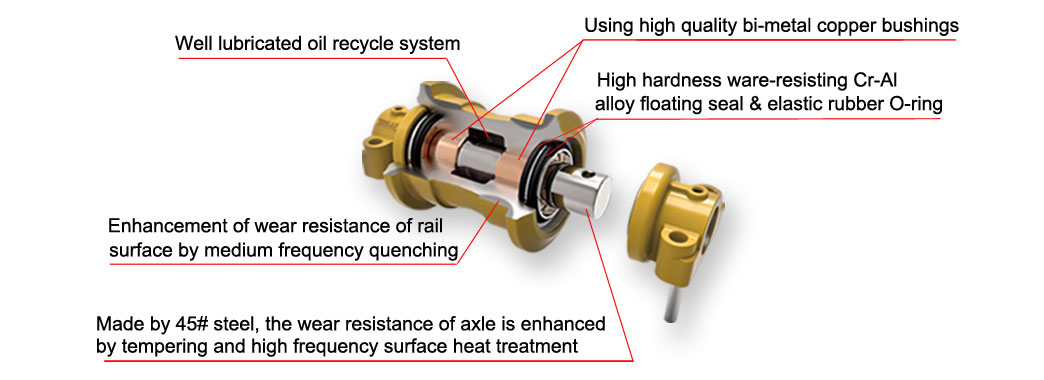

Advanced Germany KUKA automatic machining center, horizontal and vertical CNC machining ensure the accuracy of assembly dimensions. This is to maximize the life span of each component and minimize production cost.

-

Through quench-tempering processes to ensure excellent mechanical properties, high strength and superior wear resistance to bending and breakage.

-

Shaft uses high-quality manganese steel, quenched and tempered, high-frequency processing, it can meet the needs of high-intensity operations.

-

Panasonic automatic welding robot from Japan makes sure we have steady and good welding quality.

-

35 years' experience in Excavator & Bulldozer spare parts manufacturing.

2. Manufacturing Processes

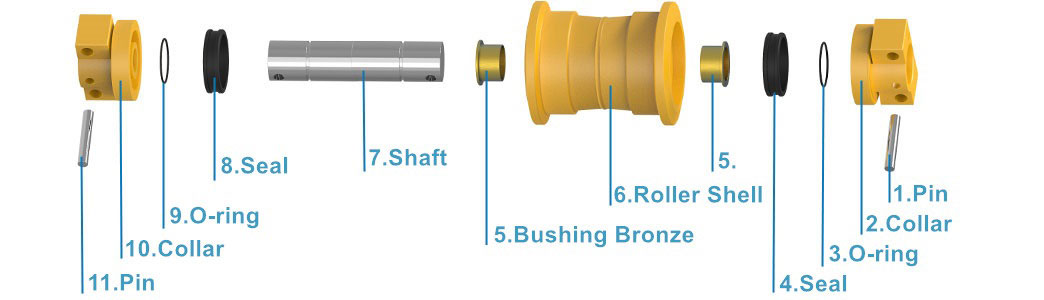

3. Track Roller Structure

4. Hot Sales

5. Compatible Brands