Product Description:

1. Polytetrafluoroethylene scraping board cater to the body of the blending groove and scrape out viscosity material on the boiler wall.

2. Two set disperser is installed on bottom to increase motor power more thoroughly and strongly. One powder mixer pot, for mixing powder, During a few produce, it can exert dispersing effect fully

3. Mightiness balance isotactic curve rotor is matched with stator with corresponding structure to realize liquid high-capability cut、rubbing, centrifugal to make sure exquisite and slick paste; machine body and pipe surface mirror polishing accords with Daily Chemical and GMP regulation.

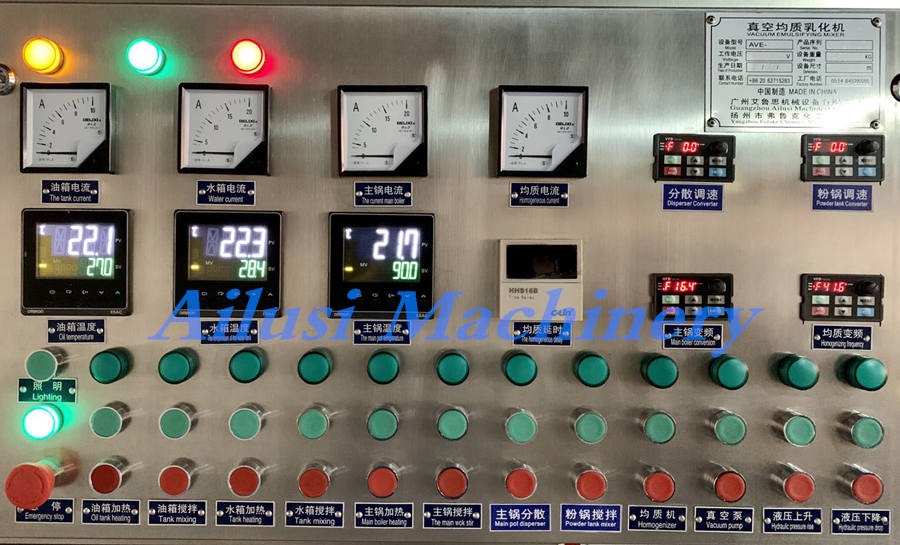

Homogenizer Mixer Type and Liquid Application electric Toothpaste Making Machine is mainly composed of water pot, oil pot, powder pot, emulsifying pot, vacuum system, lifting system(optional), electronic control system (PLC is optional), operation, etc.

Customer can choose frequency conversion timing disperser and highest rotate speed is 1440 r/min.

Product Parameters:

|

Working capacity (L)

|

Agitator power (kw)

|

Speed (rpm)

|

Homogenizer power (kw)

|

Speed (rpm)

|

Oil/Water tank (L)

|

Agitator power (kw)

|

Speed (rpm)

|

Hydraulic (KW)

|

|

50

|

1.5

|

0~75

|

2

|

0~3600

|

20/45

|

0.37/0.37

|

0~1440

|

0.75kw

|

|

100

|

2.2

|

0~75

|

3

|

0~3600

|

40/90

|

0.55/0.55

|

0~1440

|

0.75kw

|

|

200

|

3

|

0~75

|

5.5

|

0~3600

|

80/180

|

0.75/0.75

|

0~1440

|

1.1kw

|

|

300

|

4

|

0~75

|

5.5

|

0~3600

|

120/270

|

1.1/1.1

|

0~1440

|

1.5kw

|

|

500

|

4

|

0~75

|

7.5

|

0~3600

|

200/450

|

1.5/1.5

|

0~1440

|

1.5kw

|

|

1000

|

5.5

|

0~75

|

11

|

0~3600

|

400/900

|

2.2/2.2

|

0~1440

|

2.2kw

|

|

2000

|

7.5

|

0~75

|

15

|

0~3600

|

800/1800

|

2.2/2.2

|

0~1440

|

-

|

|

3000

|

11

|

0~75

|

18.5

|

0~3600

|

1200/2700

|

3/3

|

0~1440

|

-

|

Packing:

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Maintenance service.