|

Material:

|

High

purity acid-washed 93% quartz stone, 7% polymer material and a small amount

of inorganic pigment.

|

|

Item No:

|

SS5885 Shell White

|

|

Colors

|

white, black, red, beige, blue, and customized

colors. etc.

|

|

Size:

|

Slabs size: 3000x1400mm,

3000x1600mm, 3200x1600mm,etc

Countertop: 48*26".

70*26", 78*26", 96"x26", 108"x26"

Vanity top:

22"x25", 22"x31", 22"x37", 22"x49",

22"x61", 22"x73"

Island: 72"x36",

96"x36", 96"x40", 108"x44"

|

|

Temperature Resistance

|

≥300ºC

|

|

Surface

|

Polished or honed or customized.

|

|

Samples

|

Free

Small Quartz Sample

|

|

MOQ

|

100

Square meters

|

|

Application

|

table

tops, vanity top,worktops, bar tops, bench top, Floor ,etc.

|

With a variety of hues, veining and style there is no doubt you will

find a quartz that will fit your kitchen or bathroom perfectly. With this man-made quartz surface, you can

have your gorgeous kitchen or luxurious bathroom without having to worry

about messing it up. That’s because

quartz provides a high-glamour look and nearly life-long durability. The

benefits of quartz countertops have certainly won us over:

-- One of the benefits of quartz is that there are many color and

texture options available. Consistent, uniform appearance.

-- Quartz stone has the virtue of anti-aging and fastness. Under

room temperature, quartz stone keeps in stable.

--Quartz countertops require limited care and low maintenance. Their

non-porous nature makes them an easy care material.

--Quartz never requires polishing, buffing or sealing.

--Quartz countertops resist stain and corrosion without any need to

seal the top.

--Quartz countertops have a higher heat resistance.

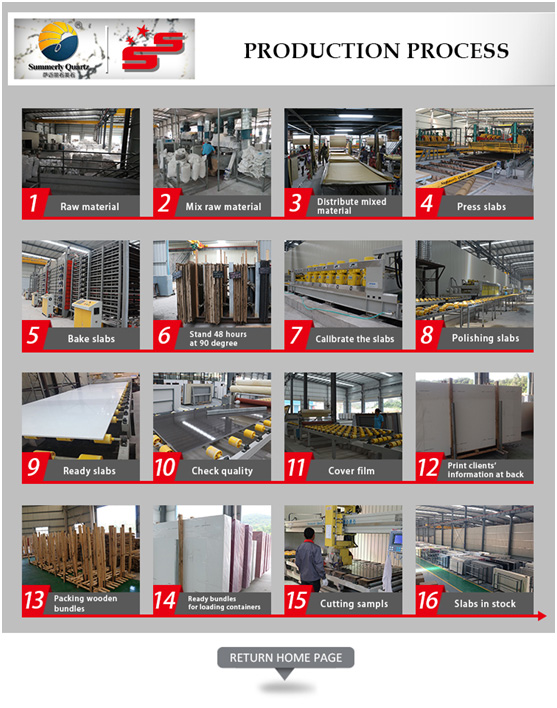

Production Engineering:

1. The process begin with a rigorous

inspection of raw materials.

2. Feeding natural quartz raw material and

polymer resins and inorganic pigments in to mixers and blending them together.

3. After stirring the mixture, then pouring

them into a mold and form them into slab size.

4. Pressing: Then the slab is compacted by a

special vacuum and vibration process at pressure machine.

5. The slab then moved to the curing kiln and

heated for a period time which give them ultimate strength and solidity.

6. Trimming edges, leveling , thicknessing

and polishing surface to perfect finished.

7.Finally, the quartz stone slabs passed

through quality inspection and packed with a plastic film.

Packing wooden

crate (slab) wooden box (tiles/

countertop)