Bonve rotary Lobe Pumps for lube oils

Lube oils are liquid or semi-solid

lubricants used in various types of automobiles and machinery to reduce

friction and protect machines and machined parts. Mainly used for lubrication,

cooling, rust prevention, cleaning, sealing and cushioning.

The problem

Screw pump and gear pump are normal to

see for lube oil transferring. But usually users will face below problems

|

Screw pumps

|

|

Heavy damage might be

caused due to dry run

|

|

Sensitive to the change

of viscosity

|

|

The fluid may leak out of

the pump body and cause pollution to the environment and the pump body.

|

|

Maintenance is

inconvenient

|

|

Gear pump

|

|

The inter-tooth groove of

the end cap and gear constitutes a number of fixed sealing working chambers,

which can only be used as a dosing pump

|

|

Unbalanced radial force,

large flow artery, high noise

|

|

Low efficiency, poor

interchangeability of parts, difficult to repair after wear

|

|

High cost of wearing part

to replace

|

The solution

With the characteristics of low rotation

speed and high output torque, Bonve rotary lobe pump shows his talents to

transfer high viscosity lub oils. Its unique working principle works with a

strong drive system, ensure that the pump can output a strong driving torque at

low speed, can guarantee continuous, non-stagnant transferring.

Advantages of Bonve Lobe Pumps

-

Gap is kept between the

rotors to allow no friction, thus to ensure long service life.

-

Simple installation and

disassembling easy maintenance and cleaning, strong resistance to wearing.

-

High efficiency and energy-

saving, stable transmission, low failure rate, good sealing and low noise.

-

A heat retaining device can

be built in structure.

-

Suitable temperature: 1~250c

degree.

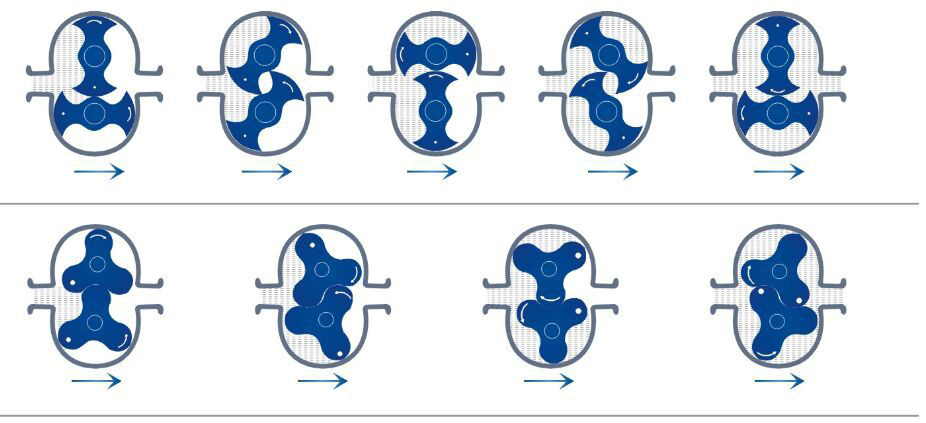

How Bonve Lobe pump works?

The even rotation of the rotor pair creates a vacuum on the

priming side of the pump, which can be defined by the direction of rotation of

the drive. This vacuum draws the liquid into the pump chamber. With further

rotation, the pumped medium is conveyed past the pump wall into the pressure

area. Up to six chamber charges are displaced with each drive rotation– depending on the rotor type. When the rotor is at a

standstill, the pump seals off almost

completely.

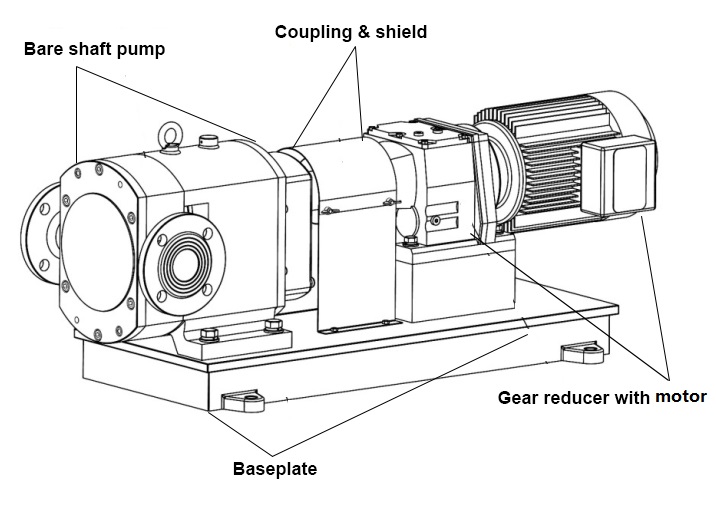

Pump

main structure

Pump

structure advantage

Pump main technical parameters

|

Model

|

Displace

-ment

(L/r)

|

Rotation

speed

(r/min)

|

Flow

rate

(M³/h)

|

Dis.

Pre.

(Mpa)

|

Electrical

power

(Kw)

|

Suc.

Pre.

(Mpa)

|

Dia.

of inlet

and

outlet (mm)

|

|

25BV6 /12-2

|

0.15

|

20-600

|

2

|

0.1-1.2

|

1.1-2.2

|

-0.095

|

25

|

|

40BV6 /12-5

|

0.32

|

20-550

|

5

|

0.1-1.2

|

1.5-4

|

-0.095

|

40

|

|

50BV6 /12-10

|

0.65

|

20-550

|

10

|

0.1-1.2

|

2.2-7.5

|

-0.095

|

50

|

|

65BV6 /12-20

|

1.74

|

20-550

|

20

|

0.1-1.2

|

4-15

|

-0.095

|

65

|

|

80BV6 /12-30

|

2.48

|

20-550

|

30

|

0.1-1.2

|

5.5-22

|

-0.095

|

80

|

|

80BV6 /12-40

|

3.65

|

20-550

|

40

|

0.1-1.2

|

7.5-30

|

-0.095

|

100

|

|

125BV6 /12-50

|

4.60

|

20-550

|

50

|

0.1-1.2

|

11-45

|

-0.095

|

125

|

|

125BV6 /12-70

|

6.10

|

20-550

|

70

|

0.1-1.2

|

15-55

|

-0.095

|

125

|

|

125BV6 /12-80

|

7.63

|

20-550

|

80

|

0.1-1.2

|

18.5-75

|

-0.095

|

125

|

|

150BV6 /12-120

|

11.56

|

20-420

|

120

|

0.1-1.2

|

22-90

|

-0.095

|

150

|

|

150BV6 /12-150

|

14.22

|

20-420

|

150

|

0.1-1.2

|

37-110

|

-0.095

|

150

|

|

200BV6 /12-200

|

18.10

|

20-420

|

200

|

0.1-1.2

|

45-132

|

-0.095

|

200

|

|

250BV6 /12-250

|

22.92

|

20-420

|

250

|

0.1-1.2

|

55-160

|

-0.095

|

250

|

|

300BV6 /12-300

|

32.00

|

20-420

|

300

|

0.1-1.2

|

75-200

|

-0.095

|

300

|

How

to choose Bonve pump?

|

Selection Guideline

|

|

Liquid

name:___________

|

|

Viscosity:_______cp Density:_______ Temperature:_____℃ PH value:________

|

|

Solid content:_______ Max. size of particle:_______

|

|

Capacity: Max. required__________ L/H Working required__________ L/H

|

|

Discharge pressure: Max. required__________Mpa Working required__________ Mpa

|

|

Connection type required: Thread [ ] Clamp [ ]

|

|

Installation type: Fixed [ ] Movable [ ]

|

|

Voltage:____ V Frequency: _____Hz

|

|

Liquid contact material: SS304 [ ] 316 [ ] 316L [ ]

|

|

Special

request_____________________________________

|

|

Order qty.

|

Thanks

for your interest into our lobe pump for lube oil transferring, hope we can

solve your pumping problem. Contact our sales engineer - Mr. Hank Li for a pump

solution.

Email: bvsales1@bonvepumps.com

Tel : 0086-574-87769810

Mobile: 0086-15669501367