Standard / Customized Current transformer for GFCI, RCD Application

The GFCI component must consist of ZCT and GNT coils. The ZCT coil is used to detect a small ground Sult difference current between the live line and the earth line The GNT coil is used to detect an over-current caused by arcing or short circuit of the cable fire or

excessive current change. It is mainly used in GFCI sockets or plugs used in near-water environments such as kitchens, bathrooms, car washes, and arc fault breaker sockets or plugs for air condrtionera.

Features

√ Precision and steady output

√ Close to zero load shift

√ Excellent balance characteristics

√ Superior temperature stability

Items & Specification

|

Model No.

|

Electrical Characteristics

|

Dimension(Unit:mm/inch)

|

Standard PN

|

|

Ip(A)

|

I(mA)

|

Rl(Ω)

|

ZCT:V(mV)

|

A

|

B

|

C

|

D

|

E

|

F

|

Pin

|

|

f(Hz)

|

u(V)

|

GNT:Ls(mH)

|

|

523

|

20

|

5

|

1K

|

3.5-4.2

|

16

|

17.85

|

11.5

|

5

|

11

|

1.5

|

0.64

|

Z/G523P100

|

|

1.0K

|

1.0V

|

90-140

|

0.630

|

0.703

|

0.453

|

0.197

|

0.433

|

0.059

|

0.025

|

|

524

|

20

|

5

|

1K

|

3.5-4.2

|

17.2

|

11

|

3.6

|

14

|

18.6

|

7

|

0.64

|

Z/G524P100

|

|

1.0K

|

1.0V

|

90-140

|

0.677

|

0.433

|

0.142

|

0.551

|

0.732

|

0.276

|

0.025

|

|

530

|

30/50

|

5

|

1K

|

4.1±0.5

|

38.00

|

19.80

|

16.50

|

42.60

|

2.12

|

6.18

|

0.640

|

Z/G530P100

|

|

1.0K

|

1.0V

|

100±25

|

1.496

|

0.780

|

0.650

|

1.677

|

0.083

|

0.243

|

0.025

|

|

537

|

20/30

|

5

|

1K

|

3.5-4.2

|

16

|

20.5

|

15.8

|

13.3

|

15.2

|

3.2

|

0.640

|

Z/G537P100

|

|

1.0K

|

1.0V

|

90-140

|

0.630

|

0.807

|

0.622

|

0.524

|

0.598

|

0.126

|

0.025

|

|

542

|

20/30

|

5

|

1K

|

3.5-4.2

|

17.465

|

5.5

|

23.4

|

11.1

|

19.9

|

7.5

|

0.8

|

Z/G542P100

|

|

1.0K

|

1.0V

|

90-140

|

0.688

|

0.217

|

0.921

|

0.437

|

0.783

|

0.295

|

0.031

|

|

556

|

20

|

5

|

1K

|

3.5-4.2

|

16.9

|

5.21

|

10.5

|

3.18

|

6.36

|

17.4

|

0.64

|

Z/G556P100

|

|

1.0K

|

1.0V

|

90-140

|

0.665

|

0.205

|

0.413

|

0.125

|

0.250

|

0.685

|

0.025

|

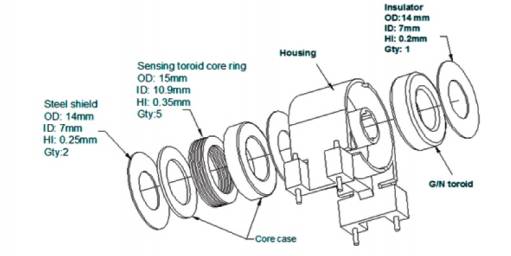

Typical structure of GFCI Current Transformer

Production Process

Implement ISO9001 / 14000 / IATF16949 to meet electrical and electric manufacturing and automobile industry requirement.

Testing

A series incoming and outcoming inspection ensure our products have high quality to meet customers requirement and outcoming pass rate less then 10PPM.

Packing and Shipping

We are specialized in current transformer for GFCI / RCD, providing customized service and expertise in consulting, design and manufacturing of current transformers for GFCI.

Contact us today to discuss your project!