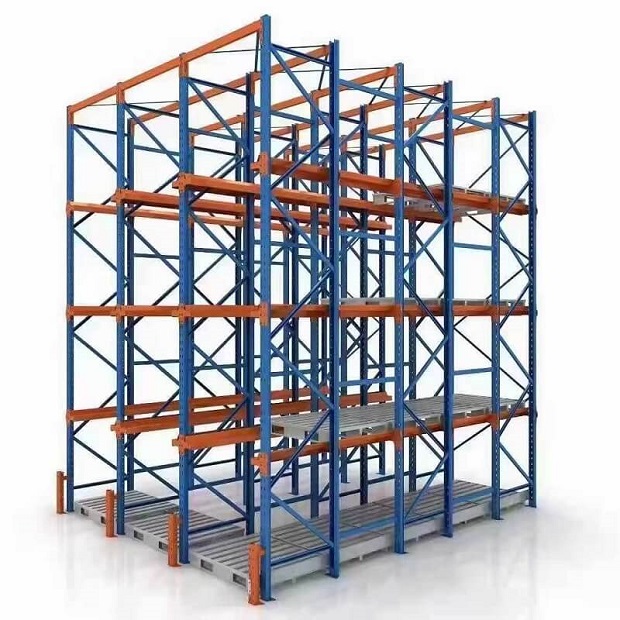

Steel Industrial Warehouse Drive In Racking System

Warehouse Pallet Drive In Rack provides the space efficiency and high volume storage of block stacking, with easy access to pallets.There are no aisles , providing maximum space efficiency. And because each pallet sits on its own support rails, pallets are no longer stacked on top of each other.Stable and highly space efficient, drive-in racking provides maximum use of storage volume together with fast input and retrieval of pallets.The Drive In Rack is tailored to pallet and load size and handling equipment.It can be used with standard handling equipment,rails adjustable optimize space utilization.

Product Feature

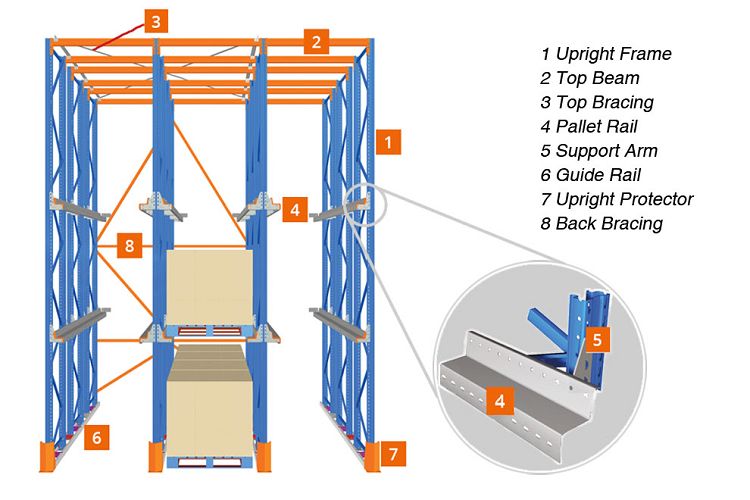

Drive In (Drive Through)Pallet Racking Systems are ideal for facilities that store large amounts of the same items. You can store up to 75% more pallets than with conventional pallet rack and your over square footage needs can be reduced by up to 35%. This pallet racking system is made up of a set of racking units that form inner loading aisles that have support rails for the pallet loads to rest on. The forklifts enter these inner aisles with their loads held higher than the level at which it is to be deposited. Each loading aisle has support rails on both sides. These are arranged on different levels and the pallets are placed on top. Drive In pallet racks - you use the same entry and exit point on each aisle,storage bay to access your loads, creating last-in/first-out storage. Drive-Through pallet racks you can use both the front and back of each aisle,storage bay to access your loads, creating first in,first-out storage. Height and depth can be designed to meet your specific needs.

1 Most cost-effective high-density storage rack

2 Excellent solution for large volume storage of like product

3 May be able to use existing forklift equipment

4 Allows for use of either roll-formed or structural rack materials

5 Forklift has straight access to product loads, allowing for deeper pallet storage

6 Drive In is a LIFO (last in, first out) storage system

How to get a quotation?

In order to provide most appropriate quotation with detail solution, please give us as follow details in advance:

1: The racking dimension and total quantity.

2: Usage areas and layout plan.

3: Loading capacity you expect.

4: Other details such as the temperature of cold storage,the height of warehouse,and so on.

FAQ

Q:Are you a manufacture or just a trading company?

A:We are a manufacturer and exporter,we have 2 factories in Xiamen and Jiangsu,an independent export company --Xiamen Keeptop.

Q: Can you provide the layouts?

A: We have a professional design team to attend your OEM/ODM requests.

Q What is the delivery time?

A: It is about 10-15 days for a 40' container.

Q: What is your after-sales service time?

A: We guarantee after-sale service in 24 hours.